5S Chart

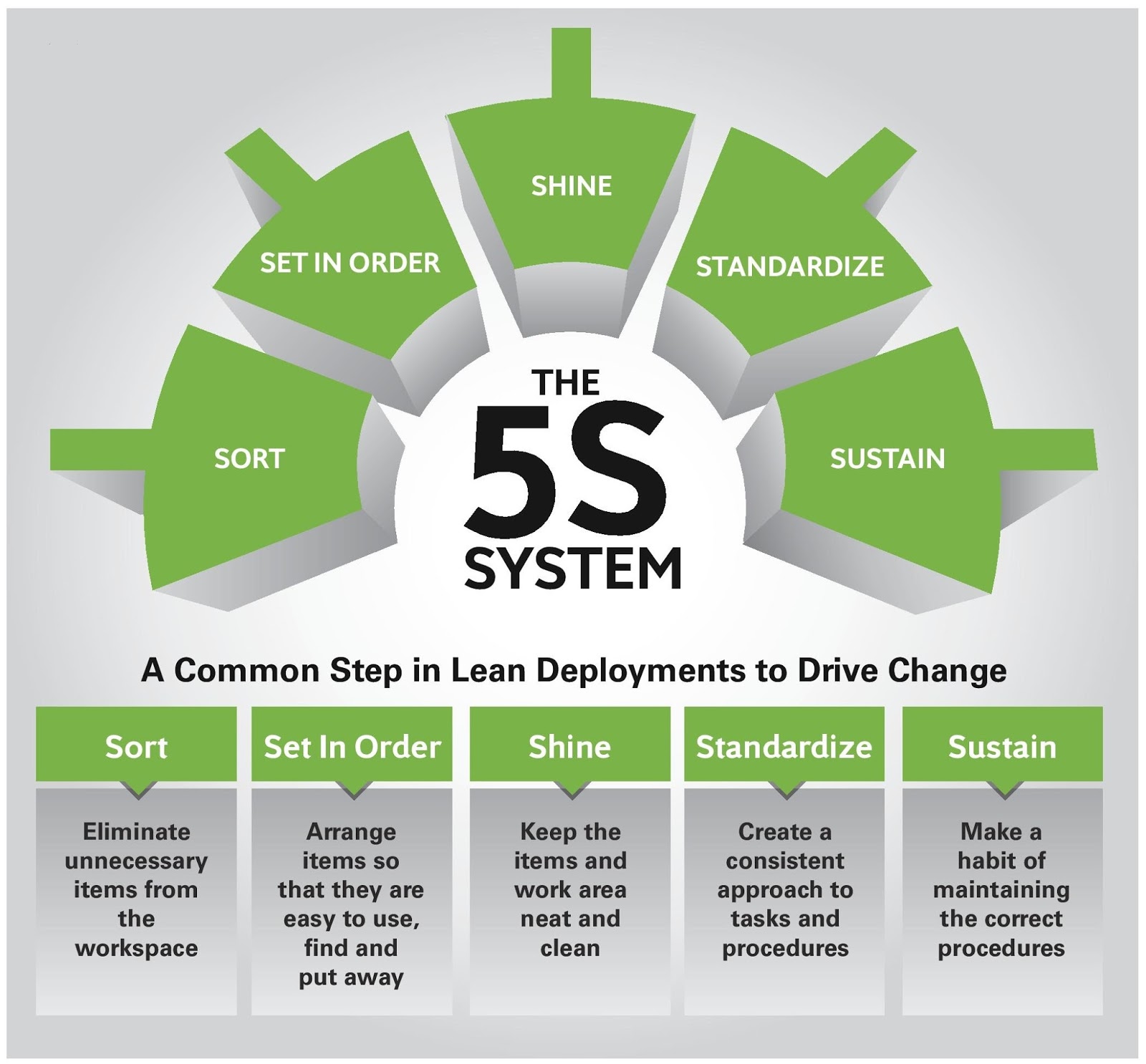

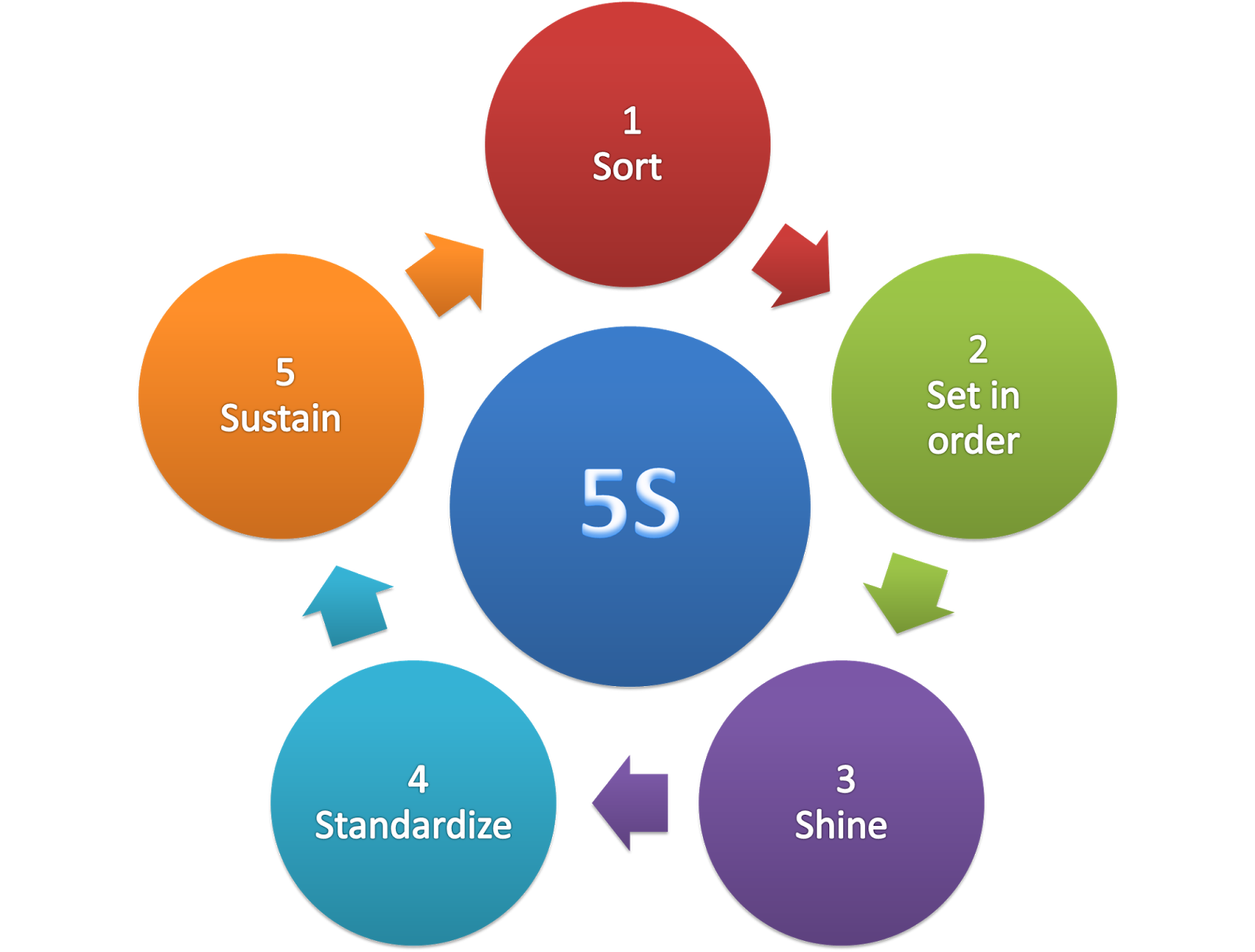

5S Chart - What is a radar chart? In english, the 5s’s are: Web some of the tools used in standardizing the 5s procedures are: Web 5s is a systematic way of organizing workplaces by eliminating waste, improving flow, and reducing the number of processes where possible. 5s was originally a japanese organization method composed of the terms: This 5s management template can be used in many industries including manufacturing, environemental sectors and more. Download a variety of lean. Ensure 5s is a way of life by making the first four ss habits. Missing a deadline can send ripples of chaos throughout an entire project. 1 sort 2 set in order 3 shine What does 5s stand for? Web 5s is sometimes called the five pillars because just like the physical pillars that hold up a structure, 5s has five elements that support the effectiveness of the system. There are a number of benefits to using the 5s system to reorganize your workplace: What is the purpose of 5s? 5s is a process. What is the 6th s? Web visual workplace and 5s go hand in hand. In each of the 5s stages namely: This simple and easy to read chart depicts common colors used by the 5s method and what each color should be used for. Rich the content of this template with more details fo the five steps to maintain a. Missing a deadline can send ripples of chaos throughout an entire project. How does 5s relate to kaizen? 5s was originally a japanese organization method composed of the terms: And just like the pillars of a building, if one was to weaken or fail, the entire structure would fall. Web some of the tools used in standardizing the 5s procedures. From that perspective, 5s is a method, while creating a visual workplace is the goal. Standardize your organizational method by color with this free 5s color chart. 5s is a mnemonic for remembering the five pillars of the visual workplace. Rich the content of this template with more details fo the five steps to maintain a good organizational productivity. One. Rich the content of this template with more details fo the five steps to maintain a good organizational productivity. This simple and easy to read chart depicts common colors used by the 5s method and what each color should be used for. In each of the 5s stages namely: What are the five s's (5s) of lean. Web 5s management. Web 5s is a systematic way of organizing workplaces by eliminating waste, improving flow, and reducing the number of processes where possible. Web 5s is a system for organizing spaces so work can be performed efficiently, effectively, and safely. 5s is a mnemonic for remembering the five pillars of the visual workplace. What is the purpose of 5s? This 5s. Download a variety of lean. 5s is the foundation for continuous improvement, zero defects, cost reduction, and a safe work area. Sort (seiri), set in order (seiton), shine (seiso), standardize (seiketsu), and sustain (shitsuke). Seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). This method is simply done using a radar chart. Sort, straighten, shine, standardize, and sustain. One of the main purposes of 5s is to prepare the work environment to hold visual information. Standardize your organizational method by color with this free 5s color chart. Web 5s management chart template. 5s is a mnemonic for remembering the five pillars of the visual workplace. Make cleaning a part of everyday life. Benefits of the 5s system. This method is simply done using a radar chart. What are the five s's (5s) of lean. There’s also an additional sixth “s.” considering that a large benefit of 5s is eliminating waste, the inclusion of this extra “s” makes perfect sense. 5s is the foundation for continuous improvement, zero defects, cost reduction, and a safe work area. In each of the 5s stages namely: Web 5s is a workplace organization method that uses a list of five japanese words: Keeping track and grading 5s accomplishments is the essence of 5s metrics. 5s was originally a japanese organization method composed of the. 5s enables anyone to distinguish between normal and abnormal conditions at a glance. Sort, straighten, shine, standardize, and sustain. Seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). Web visual workplace and 5s go hand in hand. 5s is the foundation for continuous improvement, zero defects, cost reduction, and a safe work area. Missing a deadline can send ripples of chaos throughout an entire project. Web 5s is a system for organizing spaces so work can be performed efficiently, effectively, and safely. There’s also an additional sixth “s.” considering that a large benefit of 5s is eliminating waste, the inclusion of this extra “s” makes perfect sense. Web 5s color chart quick guide. Ensure 5s is a way of life by making the first four ss habits. One of the main purposes of 5s is to prepare the work environment to hold visual information. There are a number of benefits to using the 5s system to reorganize your workplace: What is the 6th s? And safety guides for free. Sort (seiri), set in order (seiton), shine (seiso), standardize (seiketsu), and sustain (shitsuke). What does 5s stand for?

HSE Insider The 5S System

5S methodology management chart diagram with Sort. Set in order. Shine

What is 5S? 5S System is explained including tips on getting a 5S

Lean Laboratory 5S for the Laboratory

5S Templates Free To Print

Free 5S Management Chart Template

Explained 5S Framework Beginner's Guide L6S

5S Methodology Management With Circle Arrow Roll Chart. Sort. Set In

Article Understanding the 5S's of Kaizen 6 Sigma

The 5S Cycle Creative Safety Supply

Make Cleaning A Part Of Everyday Life.

5S Serves As A Foundation For Deploying More Advanced Lean Production Tools And Processes.

From That Perspective, 5S Is A Method, While Creating A Visual Workplace Is The Goal.

This Simple And Easy To Read Chart Depicts Common Colors Used By The 5S Method And What Each Color Should Be Used For.

Related Post: