Aluminum Tig Welding Settings Chart

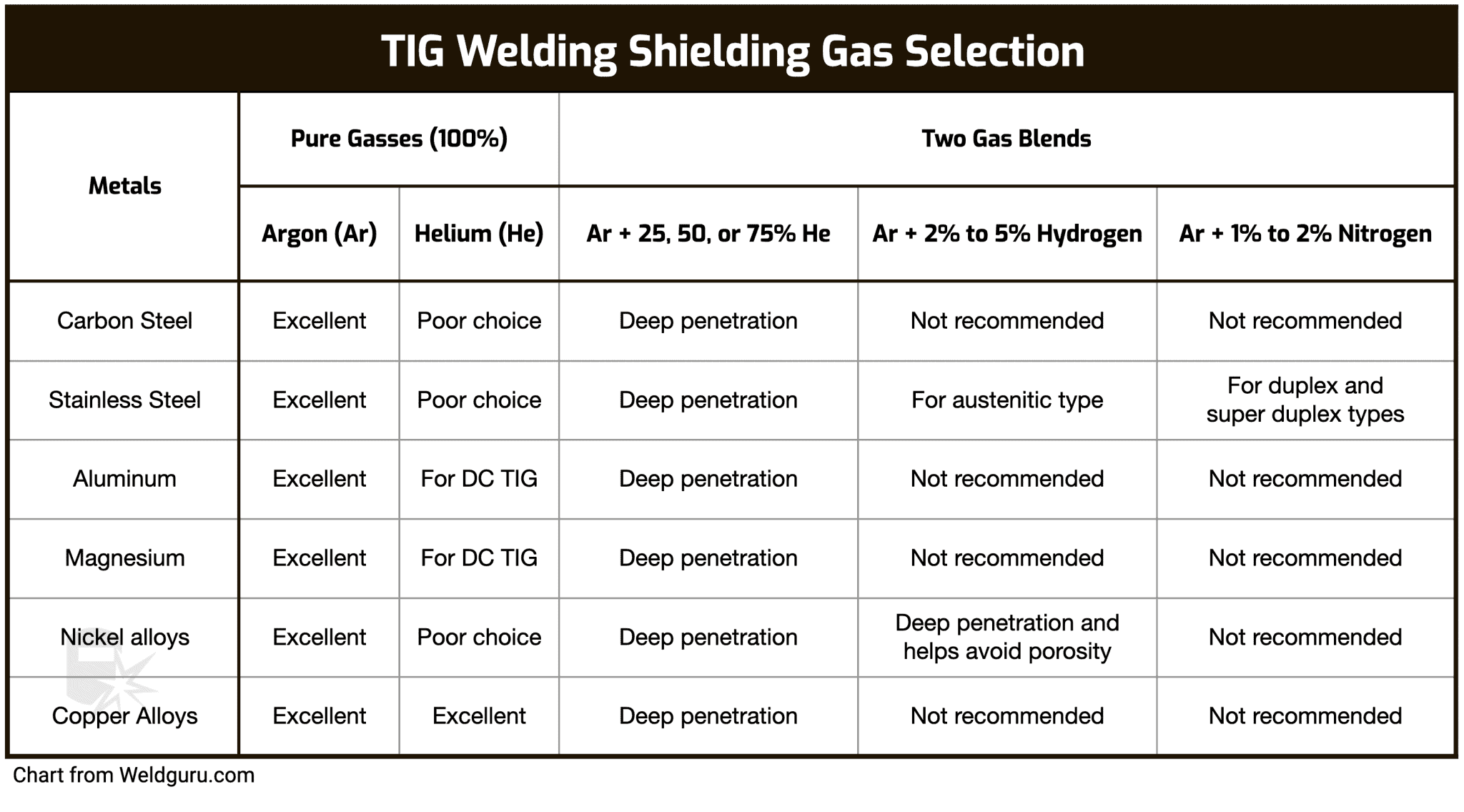

Aluminum Tig Welding Settings Chart - Tap the bottom row buttons. Many operators, especially those new to aluminum welding, may not. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. Browse suggested weld parameter settings for tig welding. 3 applications of tig welding with aluminum. Web in addition to properly controlling heat, consider these seven tips to optimize results when welding aluminum with gtaw. Web this guide contains extremely valuable information to anyone who starts this kind of welds on aluminum for the first time, from current settings to weldability with other materials. (tig) welding parameters aluminum titanium magnesium stainless steel deoxidized copper Web the standard in tig welding 2 toll free: Choosing the right equipment (right type of tig welder) selecting the right tungsten electrode; Shield gas selector chart 4guide for shield gas flows, current settings, cup selection. Web the standard in tig welding 2 toll free: A filler rod is often fed into the weld pool by the operator to create a weld. Web tig welding chart based on material and shielding gas. Tap the bottom row buttons. View full size chart here. Tig (gtaw) welding is one of the cleanest and best ways to weld aluminum. Carbon steel, stainless steel and aluminum can all be welded using pure argon shielding gas. For aluminum welding, switch your amperage setting on the front panel to ac. It outlines the optimal settings based on material thickness and joint type. Turn on the machine and the rear panel. Choosing the right gas & connecting the gas supply; Important questions to ask before tig welding aluminum. Web for tig welding www.ckworldwide.com toll free ordering tel: Web tig welding chart based on material and shielding gas. Download the app version of the weld setting calculator for easy reference! The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. 2 what parameters are important in tig welding? Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Navigate the difficulties unique to aluminum. (for stick welding, switch your amperage setting to dcep.) 5. Aluminum tig welding for beginners: Turn on the machine and the rear panel. Navigate the difficulties unique to aluminum welding. Important questions to ask before tig welding aluminum. Choosing the right wire, shielding gas & gun. Shield gas selector chart 4guide for shield gas flows, current settings, cup selection. What current setting to use for tig welding aluminum? Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web what are the tig welding parameters for aluminum? 2 what parameters are important in tig welding? Tig (gtaw) welding is one of the cleanest and best ways to weld aluminum. What are the tig welding parameters for aluminum? Web what are the tig welding parameters for aluminum? Choosing the right wire, shielding gas & gun. The issue with tig welding aluminum is that it can be daunting for beginner welders. For steel and steel alloy welding, switch your amperage setting to dcen. Whether you’re new to pulsed tig welding or trying to get the stacked dimes look, selecting the right settings is the key to success. Web below is a quick guide for selecting the. A filler rod is often fed into the weld pool by the operator to create a weld. It outlines the optimal settings based on material thickness and joint type. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. It caters to different material types and thicknesses for effective welding. Tap the bottom row buttons. Tig (gtaw) welding is one of the cleanest and best ways to weld aluminum. The aluminum settings require you to use pure tungsten or thoriated tungsten with a green, red and yellow band. Web tig welding chart based on material and shielding gas. What current setting to use for tig welding aluminum? Important questions to ask before tig welding aluminum. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Choosing the right equipment (right type of tig welder) selecting the right tungsten electrode; The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. Quick pointers to refine your skills and results. For aluminum welding, switch your amperage setting on the front panel to ac. View full size chart here. This is basic set up information, if you have questions please leave it in the comments sections. Web aluminum settings for tig welding. (for stick welding, switch your amperage setting to dcep.) 5. The tig welding parameters for aluminum are set forth in the table below. Many operators, especially those new to aluminum welding, may not. Watch hand and torch placement. Turn on the machine and the rear panel. What metal are you welding? For steel and steel alloy welding, switch your amperage setting to dcen. Choosing the right wire, shielding gas & gun.

Imagen de Nora Thompson de DC para recortar Loca Tel

Step By Step For How To Tig Welding Aluminum Welding Discussion

Tig Welder Settings For Aluminum Thin, Thick, horizontal, vertical

Tig parameters chart MIG Welding Forum

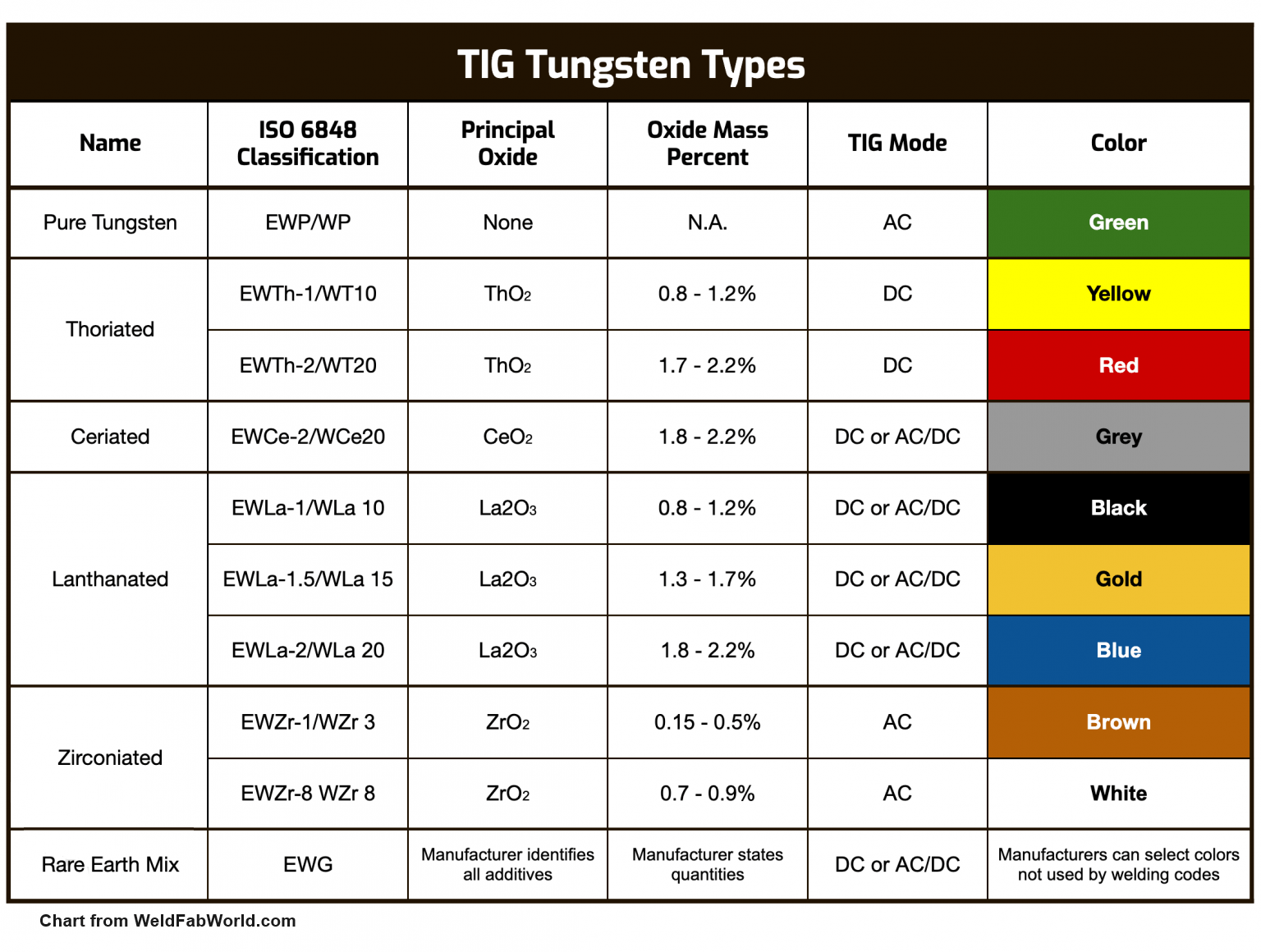

Tungsten Electrodes For TIG (with Color Chart) Welding Fabrication World

Tig Welding Settings Chart

Tig Weld Amp Chart

![Tungsten Electrode Journey to the Center of TIG Welding [2020]](https://vietmfg.com/wp-content/uploads/2020/08/tig-welding-current-ranges-for-tungsten-electrodes-1018x1024.png)

Tungsten Electrode Journey to the Center of TIG Welding [2020]

Pin by Ben on Shop Tips in 2020 Welding and fabrication, Welding

Search Result Details Welding rods, Welding tips, Welding videos

Tap The Bottom Row Buttons.

A Filler Rod Is Often Fed Into The Weld Pool By The Operator To Create A Weld.

Download The App Version Of The Weld Setting Calculator For Easy Reference!

3 Applications Of Tig Welding With Aluminum.

Related Post: