Anodize Chart

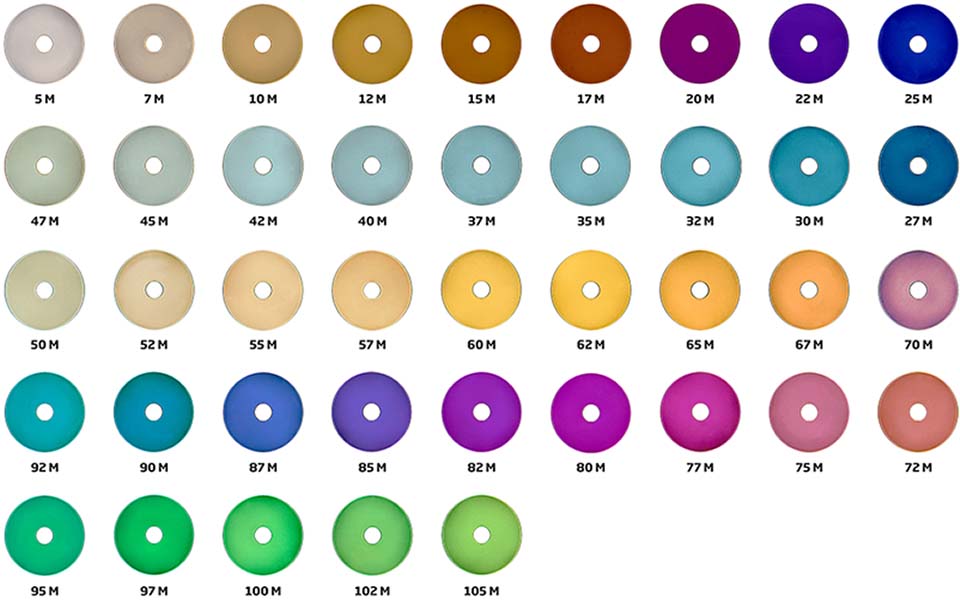

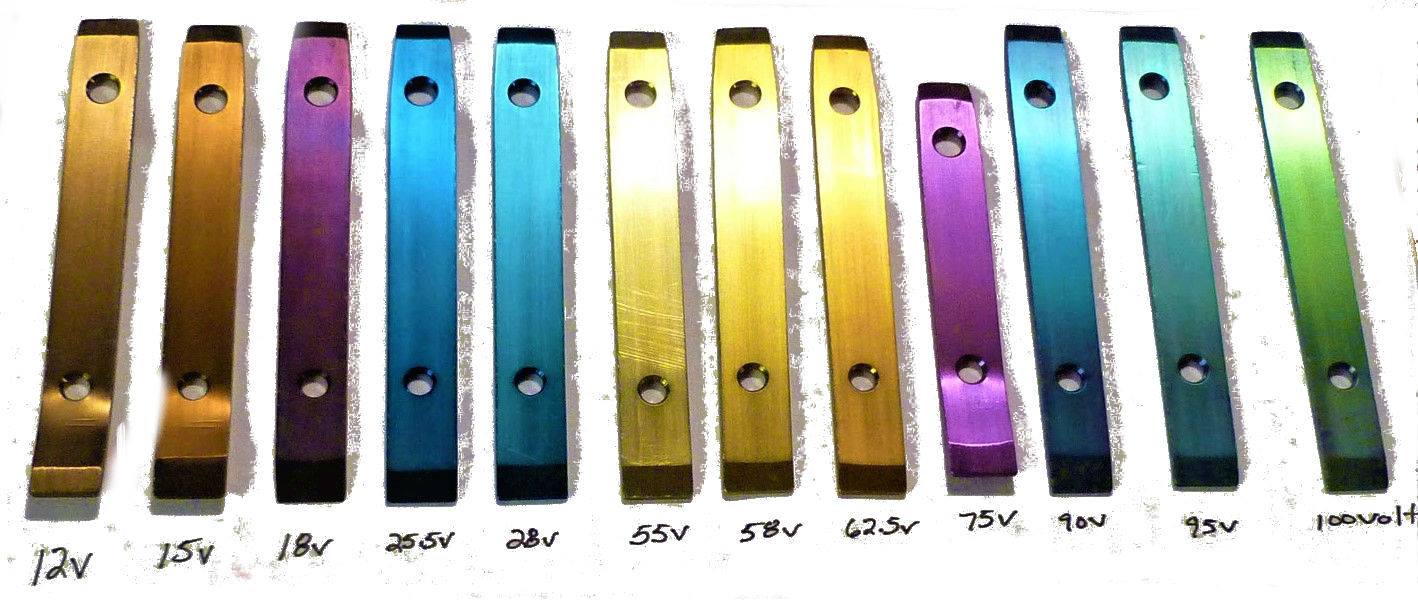

Anodize Chart - 11†(w) x 17†(h) identifies all anodized colors for titanium and niobium jewelry. Web below is a anodized titanium color chart along with voltage used to produce the color. Mechanical finishes (m), chemical finishes (c), and coatings (e.g. This layer makes it more resilient to corrosion and can also accept custom surface coloration. A very similar process can be done with aluminum, however, aluminum anodizing requires. Anodizing provides surface corrosion protection along with an excellent substrate for decorative finishes. Any titanium fasteners we sell can be custom anodized for our customers. The range here is from 0 volts to 100 volts. Web visit our titanium anodize color selector chart to explore tfc’s specific color designations. Higher voltages will build up on top of lower voltages. This oxide layer acts as an insulator and can be dyed in a wide variety of colors. Web anodized aluminum is aluminum that has been subjected to an electrochemical process called anodization, creating a protective oxide layer on its surface. Web below is a anodized titanium color chart along with voltage used to produce the color. Therefore, in this guide,. This oxide layer acts as an insulator and can be dyed in a wide variety of colors. Anodizing provides surface corrosion protection along with an excellent substrate for decorative finishes. This pdf guide from omw corp explains the basics of anodizing, the different types and specifications, and the advantages and limitations of this coating method. Anodizing is only applied commercially. Web visit our titanium anodize color selector chart to explore tfc’s specific color designations. The color obtained in the anodizing process is dependent on many factors such as aluminum alloy, temper, shape, etc., therefore it is not possible to produce an exact color match. 11†(w) x 17†(h) identifies all anodized colors for titanium and niobium jewelry. Web linetec. Web titanium anodizing color selection guide 2450 deelyn dr. Mil spec 8625 f and test methods for type ii anodized aluminum. Parts to be dyed must be completely submerged. If you’re not sure what voltage to use, start low! Web the anodizing color samples image below illustrates the saf range of anodized bronze finishes available, as well as our class. Anodizing is only applied commercially to metals, such as: Web titanium anodizing is a process in which titanium oxides are artificially grown on top of an underlying titanium base metal using electrolysis. Web anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. 11†(w) x 17†(h). Parts to be dyed must be completely submerged. Web anodizing is a popular surface treatment for aluminum parts, but how much do you know about its process, properties and applications? It is always better to have a. However, be aware that setup is a major factor in planning for any anodizing run. Mil spec 8625 f and test methods for. The beauty of aluminum anodizing dye colors is the almost infinite number of colors available. Anodizing provides surface corrosion protection along with an excellent substrate for decorative finishes. This pdf guide from omw corp explains the basics of anodizing, the different types and specifications, and the advantages and limitations of this coating method. How does anodizing work with titanium? Mechanical. Mechanical finishes (m), chemical finishes (c), and coatings (e.g. Therefore, in this guide, we’ll take you through everything you need to know about anodizing aluminum. The beauty of aluminum anodizing dye colors is the almost infinite number of colors available. To learn more, see our guide on how to anodize aluminum. This pdf guide from omw corp explains the basics. Anodizing is only applied commercially to metals, such as: How to do type 3 color. At the end of the manufacturing process, the next stage is applying the surface finish. Parts to be dyed must be completely submerged. The beauty of aluminum anodizing dye colors is the almost infinite number of colors available. Learn how to choose the right anodizing option for. Aluminum, titanium, zinc, magnesium, niobium, zirconium, and hafnium, whose oxide. Web anodizing is a popular surface treatment for aluminum parts, but how much do you know about its process, properties and applications? However, be aware that setup is a major factor in planning for any anodizing run. Full resolution version (4k. Higher voltages will build up on top of lower voltages. How does anodizing work with titanium? However, be aware that setup is a major factor in planning for any anodizing run. Any titanium fasteners we sell can be custom anodized for our customers. Please note that the colors shown in the titanium anodize color selector chart are for general reference only and may be affected by your computer screen. This oxide layer acts as an insulator and can be dyed in a wide variety of colors. Anodizing provides surface corrosion protection along with an excellent substrate for decorative finishes. Turn on your anodizing machine and set your voltage based off your desired color. This pdf guide from omw corp explains the basics of anodizing, the different types and specifications, and the advantages and limitations of this coating method. Web anodizing is a popular surface treatment for aluminum parts, but how much do you know about its process, properties and applications? Web anodized titanium color chart along with the corresponding voltage used to produce the color. Learn how to choose the right anodizing option for. Web below is a anodized titanium color chart along with voltage used to produce the color. Web titanium anodizing is a process in which titanium oxides are artificially grown on top of an underlying titanium base metal using electrolysis. Web anodized aluminum is aluminum that has been subjected to an electrochemical process called anodization, creating a protective oxide layer on its surface. It is always better to have a.

ANODIZING JSP Grow Luxuriant

Titanium Anodizing Chart — 11 X 17 Poster ubicaciondepersonas.cdmx.gob.mx

Titanium Anodizing Voltage Color Chart

Types of Anodizing Mechanical design, Non ferrous metals, Anodized

Titanium Anodizing Voltage Color Chart — Titanium Anodizing

Anodized titanium color chart 9 thru 90 volts Oakley Forum Anodized

Anodized titanium color chart 9 thru 90 volts Oakley Forum

bob_titanium Titanium welding, Titanium, Titanium color

Toronto Cycles Titanium Anodizing at set Voltages

Titanium Anodization (See Color Chart) EDC Specialties Every Day

Full Resolution Version (4K Uhd) Of Colors Available Here:

Web Anodizing Is An Electrolytic Passivation Process Used To Increase The Thickness Of The Natural Oxide Layer On The Surface Of Metal Parts.

The Process Is Called Anodizing Because The Part To Be Treated Forms The Anode Electrode Of An Electrolytic Cell.

Parts To Be Dyed Must Be Completely Submerged.

Related Post: