C Chart

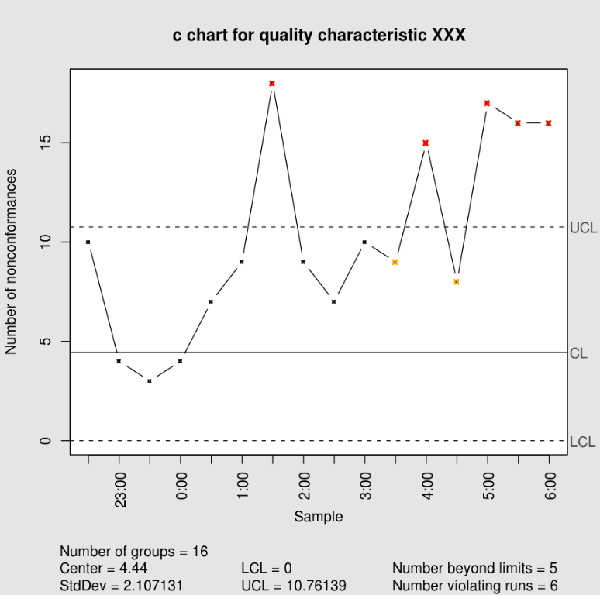

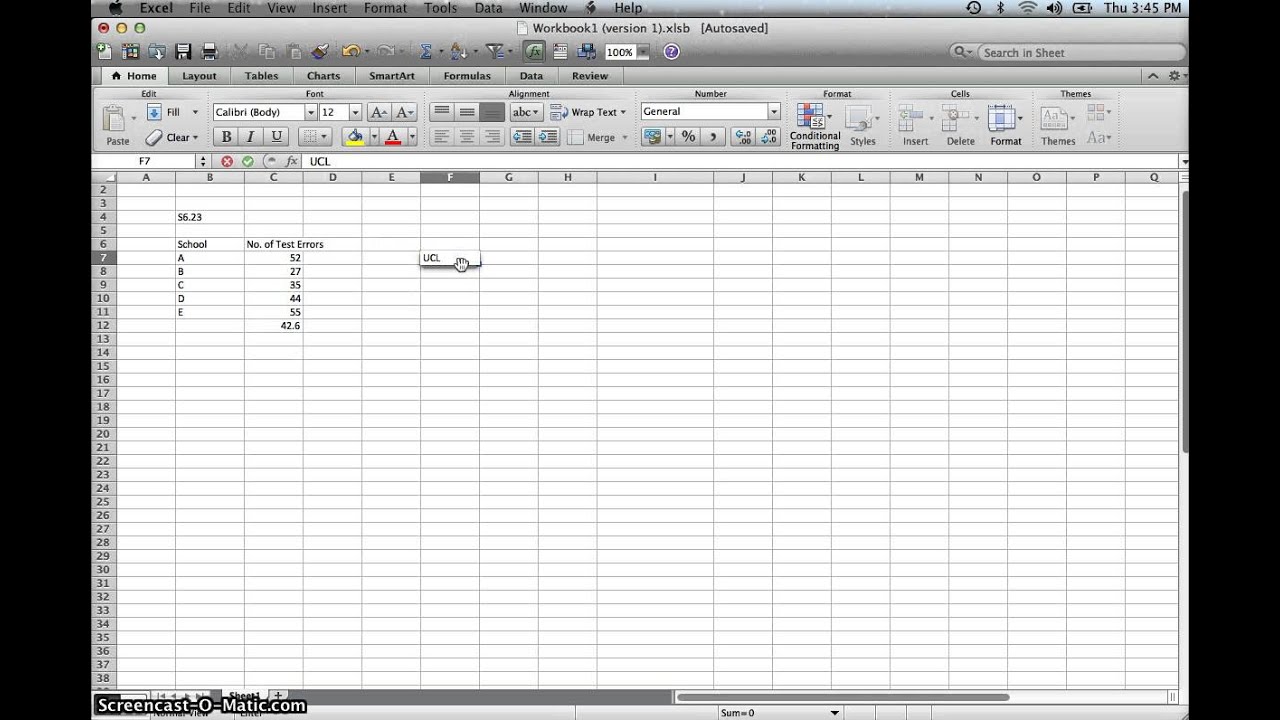

C Chart - Cᵢ = number of nonconformities found conforms with ansi/asqc b1, b2, b3 1996 stop struggling with c charts! Steps in constructing a c chart determine cbar. The sample averages and the centerline represent the present behavior of the process. Web c charts determine the stability of counted data when the opportunity is large compared to the actual number of defects ( e.g. This “unit” is commonly referred to as an inspection unit and may be “per day” or “per square foot” of some other predetermined sensible rate. The “c” in c control chart stands for “counts” as in defectives per lot. Number of defects per unit c = σc / σn = σc / m; Web a c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. It is also occasionally used to monitor the total number of events occurring in a given unit of time. The c chart is sensitive to changes in the number of defective items in the measurement process. Control charts generally have three parts: The c chart is sensitive to changes in the number of defective items in the measurement process. A quality engineer for a wallpaper manufacturer wants to assess the stability of the printing process. \({c \approx \bar{c} =}\) estimate (or average) of the number of nonconformities (defects) m = number of samples per subgroup. Steps. Web example of c chart. Web a c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. It is also occasionally used to monitor the total number of events occurring in a given unit of time. \({c \approx \bar{c} =}\) estimate (or average) of the number of nonconformities (defects) m =. It is also occasionally used to monitor the total number of events occurring in a given unit of time. \({c \approx \bar{c} =}\) estimate (or average) of the number of nonconformities (defects) m = number of samples per subgroup. The “c” in c control chart stands for “counts” as in defectives per lot. Web c charts determine the stability of. \({c \approx \bar{c} =}\) estimate (or average) of the number of nonconformities (defects) m = number of samples per subgroup. Cᵢ = number of nonconformities found conforms with ansi/asqc b1, b2, b3 1996 stop struggling with c charts! Number of defects per unit c = σc / σn = σc / m; The c chart formulas are (doty, 1996): Web. Upper control limit (ucl) = c + 3√c; Control charts generally have three parts: Every hour, the engineer takes a sample of 100 feet of wallpaper and counts the number of printing defects, which include print smears, pattern distortions, and missing ink. Web a c chart is a data analysis technique for determining if a measurement process has gone out. The c chart formulas are (doty, 1996): \({c \approx \bar{c} =}\) estimate (or average) of the number of nonconformities (defects) m = number of samples per subgroup. Control charts generally have three parts: This value is not actually used in any of the formulas. Number of defects per unit c = σc / σn = σc / m; Steps in constructing a c chart determine cbar. Number of defects per unit c = σc / σn = σc / m; This “unit” is commonly referred to as an inspection unit and may be “per day” or “per square foot” of some other predetermined sensible rate. The c chart is sensitive to changes in the number of defective items. The c chart is sensitive to changes in the number of defective items in the measurement process. The sample averages and the centerline represent the present behavior of the process. C chart is especially used when there are high opportunities for defects in the subgroup, but the actual number of defects is less. Number of defects per unit c =. Web c charts determine the stability of counted data when the opportunity is large compared to the actual number of defects ( e.g. A quality engineer for a wallpaper manufacturer wants to assess the stability of the printing process. Control charts generally have three parts: Here is the formula used to calculate a c chart. This “unit” is commonly referred. Upper control limit (ucl) = c + 3√c; The c chart formulas are (doty, 1996): A quality engineer for a wallpaper manufacturer wants to assess the stability of the printing process. Here is the formula used to calculate a c chart. Web a c chart is a control chart for monitoring the number of defects per sample. Web a c chart is a control chart for monitoring the number of defects per sample. Every hour, the engineer takes a sample of 100 feet of wallpaper and counts the number of printing defects, which include print smears, pattern distortions, and missing ink. Here is the formula used to calculate a c chart. The c chart is sensitive to changes in the number of defective items in the measurement process. Web c charts determine the stability of counted data when the opportunity is large compared to the actual number of defects ( e.g. Upper control limit (ucl) = c + 3√c; Injuries per month or falls per month). Web a c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. Number of defects per unit c = σc / σn = σc / m; The “c” in c control chart stands for “counts” as in defectives per lot. The c chart formulas are (doty, 1996): This value is not actually used in any of the formulas. The sample averages and the centerline represent the present behavior of the process. Web the c chart measures the number of nonconformities per “unit” and is denoted by c. It is also occasionally used to monitor the total number of events occurring in a given unit of time. Web a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken from a process (misra, 2008).

a1c chart Diabetes Advocacy

Pengertian C Chart & U Chart

C Chart PDF Host

SPC 4 c chart (Control Chart for number defective) YouTube

C Chart Definition, Formulas LaptrinhX

C Chart

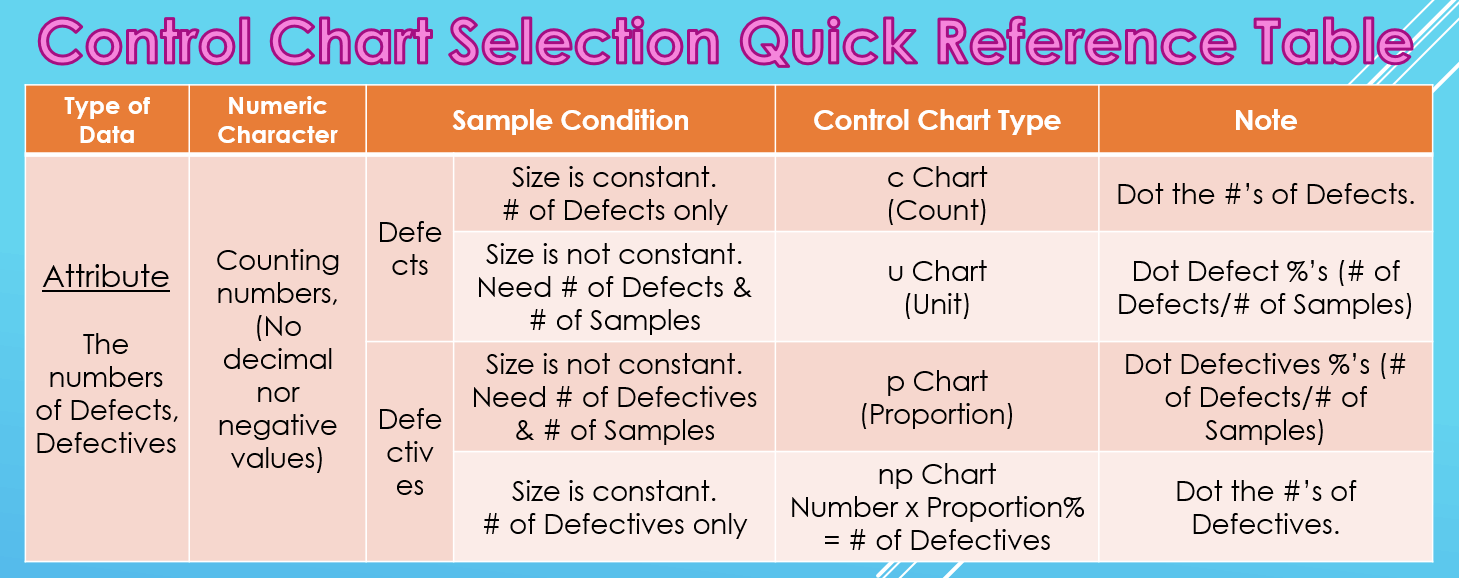

Control Chart Types You’ll understand Xbar, c, u, p, np with this

High Dose Oral Vitamin C Chart....and get 15 off your IV treatment

C Chart YouTube

c Chart Example YouTube

\({C \Approx \Bar{C} =}\) Estimate (Or Average) Of The Number Of Nonconformities (Defects) M = Number Of Samples Per Subgroup.

Sample Averages, A Centerline, And Control Limits.

A Quality Engineer For A Wallpaper Manufacturer Wants To Assess The Stability Of The Printing Process.

Steps In Constructing A C Chart Determine Cbar.

Related Post: