C Charts

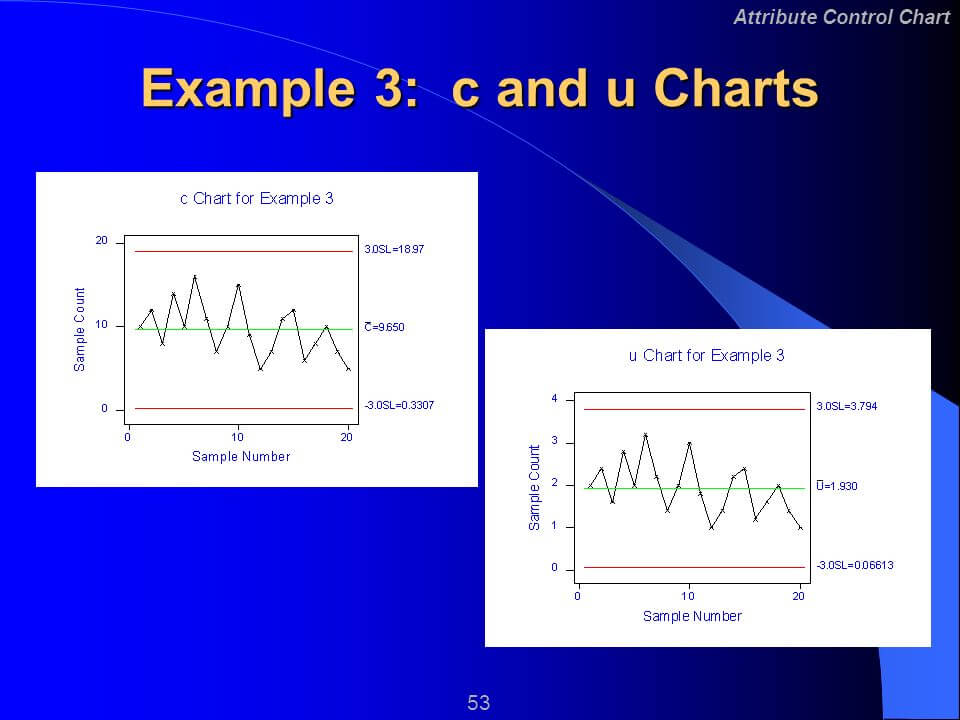

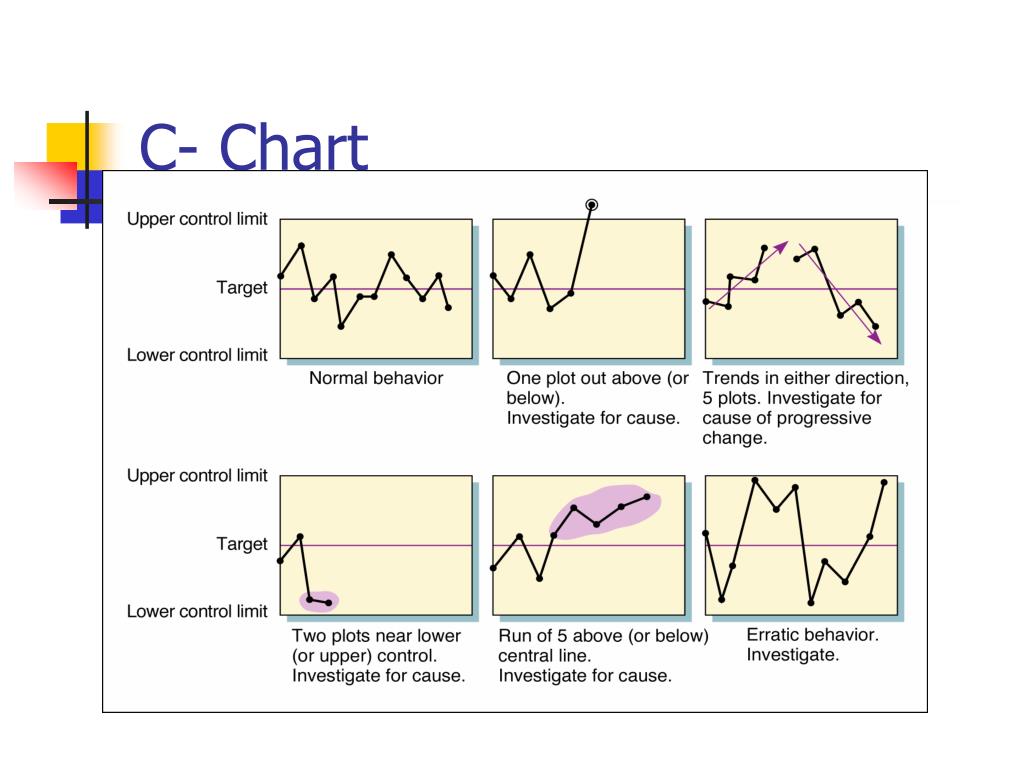

C Charts - For example, you might be counting injuries at a plant or medication errors in a hospital. Number of samples = create table. Steps in constructing a c chart. Web the c chart is one technique to use for examining variation in counting type attributes data over time. Charts, planning & navigation all via our free mobile app. All you need to navigate and find fish. Sleeve length is adjusted proportionately depending on silhouette. Each point on the chart represents the total number of nonconformities in a subgroup. C chart is especially used when there are high opportunities for defects in the subgroup, but the actual number of defects is less. Web a c chart is a control chart for monitoring the number of defects per sample. 1.75”/4.5cm longer in length than regular tops. Subgroup size usually refers to the area being examined. It is also occasionally used to monitor the total number of events occurring in a given unit of time. Sleeve length is adjusted proportionately depending on silhouette. Web c charts determine the stability of counted data when the opportunity is large compared to the. Web the c chart (plots counts) is the simplest of the attribute data control charts. Two years later, russia has engineered a wholesale rearrangement of its trade. Web a c control chart is a statistical tool used to monitor the number of defects in a process over time. Subgroup size usually refers to the area being examined. Stop struggling with. Subgroup size usually refers to the area being examined. Web control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. Use c charts for counted data: Control charts dealing with the number of defects or nonconformities are called c charts (for count). Control charts generally have. The sample averages and the centerline represent the present behavior of the process. C charts are used to look at variation in counting type attributes data. All you need to navigate and find fish. The center line is the average number of nonconformities. Conforms with ansi/asqc b1, b2, b3 1996. It is also occasionally used to monitor the total number of events occurring in a given unit of time. Web to draw a c chart: Sleeve length is adjusted proportionately depending on silhouette. The c chart is sensitive to changes in the number of defective items in the measurement process. All you need to navigate and find fish. Tall sizes are only available for select styles. For example, you might be counting injuries at a plant or medication errors in a hospital. All you need to navigate and find fish. Designed experiments (doe) regression topics. Web a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size,. For a sample subgroup (also called the inspection unit), the number of times a defect occurs is measured and plotted as a simple count. The sample averages and the centerline represent the present behavior of the process. Control charts are a simple yet powerful tool that helps us understand if a process is “stable or in control.” control charts are. Web a c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. The center line is the average number of nonconformities. Control charts dealing with the number of defects or nonconformities are called c charts (for count). All you need to navigate and find fish. Stop struggling with c charts! Injuries per month or falls per month). The c chart formulas are (doty, 1996): Control charts dealing with the number of defects or nonconformities are called c charts (for count). Control charts are a simple yet powerful tool that helps us understand if a process is “stable or in control.” control charts are used in the control phase of the. Subgroup size usually refers to the area being examined. Charts, planning & navigation all via our free mobile app. C chart is especially used when there are high opportunities for defects in the subgroup, but the actual number of defects is less. Here is the formula used to calculate a c chart. They are used to determine the variation in. Web control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. Control charts have two general uses in an improvement project. Qi macros will do the math and draw the graph for you. Web control charts are an essential tool in the six sigma methodology to monitor and control process variation. .when the opportunity is large but the number of defects is small. If you’re on the borderline between two sizes, order the smaller size for a tighter fit or the larger size for a looser fit. Subgroup size usually refers to the area being examined. Number of defects per unit c = σc / σn = σc / m. It is also occasionally used to monitor the total number of events occurring in a given unit of time. Here is the formula used to calculate a c chart. Web what are control charts? Control charts are a simple yet powerful tool that helps us understand if a process is “stable or in control.” control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. Control charts generally have three parts: Conforms with ansi/asqc b1, b2, b3 1996. 1.75”/4.5cm longer in length than regular tops. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends.

Cmap Cm93

Comparison of statistical process control charts (U and Ccharts

c charts

Control Chart 101 Definition, Purpose and How to EdrawMax Online

A1c Chart Flawed yet Functional

P chart & cchart

C How to use Chart and Graph in Visual C YouTube

CMap Digital Charts Nautical charts, books, maritime compliance and

C Chart Calculations C Chart Formula Quality America

PPT Quality Control PowerPoint Presentation, free download ID738867

The West Tried To Cut Off Russia’s Economy In Retaliation For The Invasion Of Ukraine.

Web The C Chart (Plots Counts) Is The Simplest Of The Attribute Data Control Charts.

Injuries Per Month Or Falls Per Month).

Use C Charts For Counted Data:

Related Post: