Cfm Pipe Size Chart

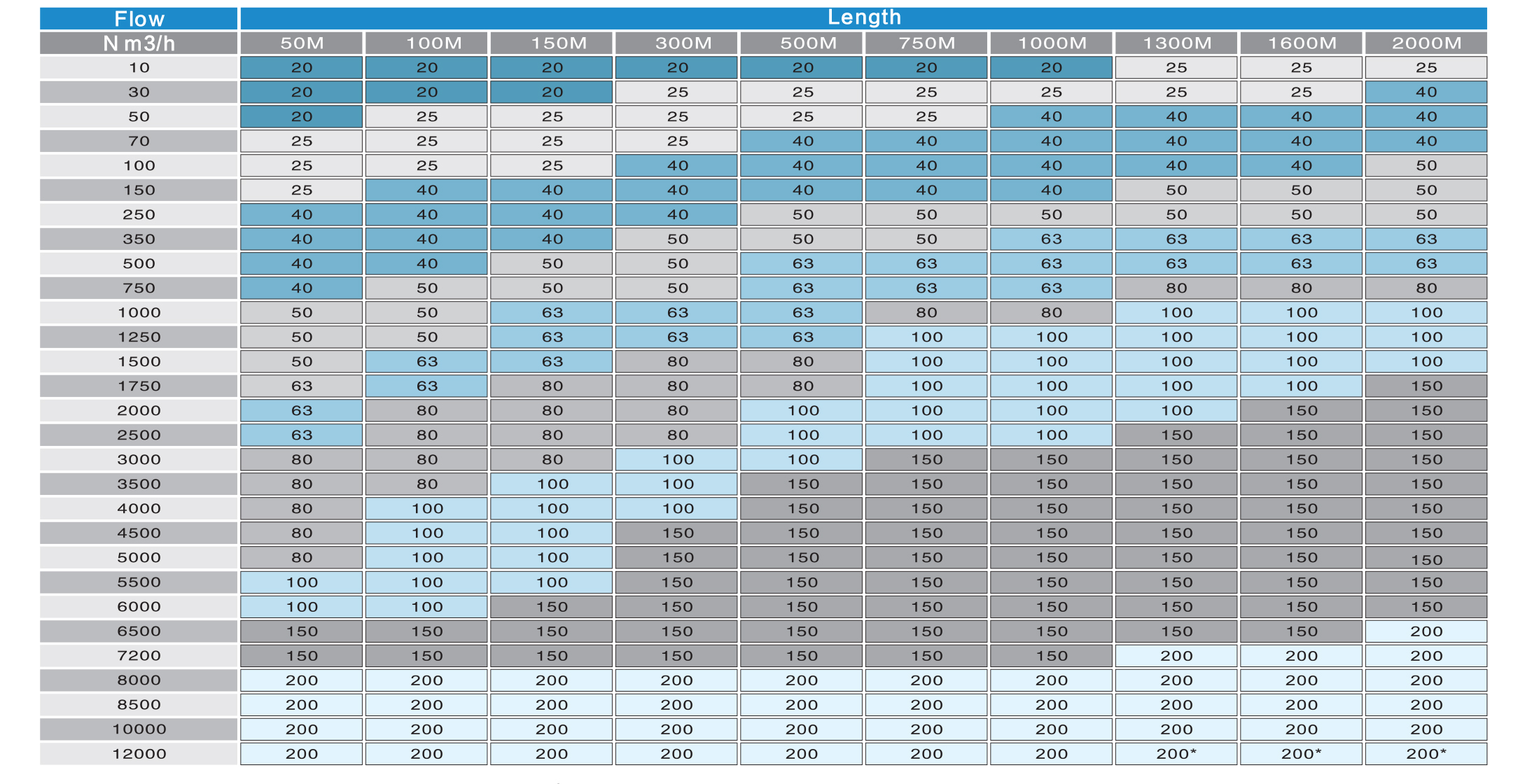

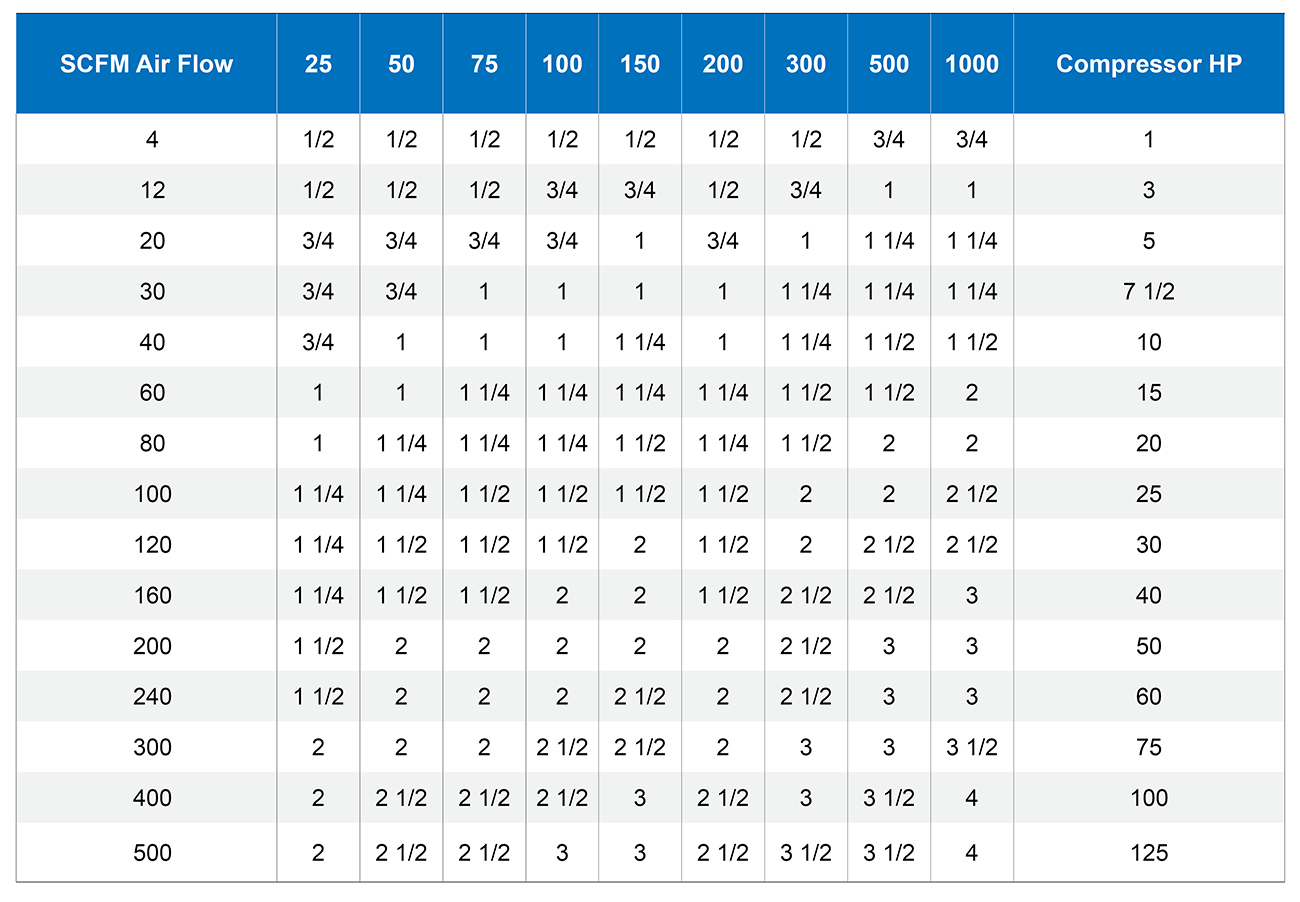

Cfm Pipe Size Chart - [ninja_tables id=”3644″] the table above measures airflow in cfm (cubic feet per minute) and measures the length of the pipe in feet. Web recommended sizes for compressed air pipe lines: Web the flow values in the table below are based on a pressure drop of 10% of the applied pressure per 100 feet of pipe for 1/8, 1/4, 3/8, and 1/2 pipe sizes; What cfm do i need for my hvac system to do its job? The generally accepted practice of 10% pressure drop for pipes up to 1/2 and 5% for 3/4 and larger should be used. Different materials need to be conveyed at different velocities to prevent the material from falling out of the air stream. 1 scfm = 0.472 nl/s. 1 inch = 25.4 mm. 12,000 btus = 1 ton. Web round flex duct: Keep in mind that the pipe size is measured in inches. Many manufacturers provide pipe sizing charts that help you select the appropriate pipe diameter based on cfm and pressure drop criteria. Refer to pipe sizing charts: Web most import tools and chip collectors are outfitted with 4 diameter ports, 4 pipe is common, 4 pipe is inexpensive, 4 pipe. Refer to pipe sizing charts: Let’s get straight into it, the following chart will help you gain a better understanding of the pipe size you need depending on the volume of airflow you have running through it, and its length! None of these reasons means that 4 pipe is the right size to run for optimal performance. Air flow (cfm). Web to make a realistic estimate of air flow volume, the far right column of the chart showing compressor hp may be used. Web using table 1, find your compressor’s cfm number on the far left column, and then go to the right until you see the column header with nearest length in feet to your total pipe length. On. Web most import tools and chip collectors are outfitted with 4 diameter ports, 4 pipe is common, 4 pipe is inexpensive, 4 pipe is the most common size of pvc pipe. What cfm do i need for my hvac system to do its job? Web factors that determine sizing in compressed air piping. Turns out this isn’t all that easy. Calculate the correct pipe size for your compressed air system. Turns out this isn’t all that easy to figure out using the math, yet i’ve tried to help as much as possible below. Web knowing the air compressor output at 90 psi output is good since many air tools are rated on their air consumption at that pressure. Web to. Web check for pressure drop: But, what if you want to know how much air your compressor puts out at 55 psi or 20 psi? Different materials need to be conveyed at different velocities to prevent the material from falling out of the air stream. Web compressed air pipe size cfm chart. For example, wood chips and saw dust flow. 1 psig = 6.9 kpa = 0.069 bar. That’s the answer to the question: Ensure that the pipe size selected can deliver the required cfm without causing excessive pressure drop. It's easy, i'll explain how. Web the flow values in the table below are based on a pressure drop of 10% of the applied pressure per 100 feet of pipe. Keep in mind that the pipe size is measured in inches. Web the flow values in the table below are based on a pressure drop of 10% of the applied pressure per 100 feet of pipe for 1/8, 1/4, 3/8, and 1/2 pipe sizes; Web round flex duct: 1 ft (foot) = 0.3048 m. Many manufacturers provide pipe sizing charts. Design elements in a compressed air pipe network. Web knowing the air compressor output at 90 psi output is good since many air tools are rated on their air consumption at that pressure. Draw a piping schematic that includes all of the lengths of pipe and all of the fittings, valves and bends in your piping system. Web this chart. Web this chart allows you to choose the correct pipe size for the cfm that is required. None of these reasons means that 4 pipe is the right size to run for optimal performance. Design elements in a compressed air pipe network. Air flow (cfm) pipe length (feet) 25. Web check for pressure drop: Friction rate and ductwork length. Web knowing the air compressor output at 90 psi output is good since many air tools are rated on their air consumption at that pressure. Web this chart allows you to choose the correct pipe size for the cfm that is required. Find where the cfm & pipe length intersect on the chart and it will show the recommended pipe size for that length. Lower pressure drop by installing the right compressed air pipe size. What is the best pipe for compressed air? Web factors that determine sizing in compressed air piping. 1 inch = 25.4 mm. Draw a piping schematic that includes all of the lengths of pipe and all of the fittings, valves and bends in your piping system. Web using table 1, find your compressor’s cfm number on the far left column, and then go to the right until you see the column header with nearest length in feet to your total pipe length. To correctly size your ductwork, you can reference the cfm sizing chart here: Based on line presssure 90 psig (620 kpa, 6.2 bar). [ninja_tables id=”3644″] the table above measures airflow in cfm (cubic feet per minute) and measures the length of the pipe in feet. Web to make a realistic estimate of air flow volume, the far right column of the chart showing compressor hp may be used. Summary of ductwork sizing factors. 1 ft (foot) = 0.3048 m.

Pipe Size Cfm Chart

CFM Pipe Size Chart Guide To Selecting Pipe Sizes, 53 OFF

Review Of How Many Cfm Per Ton Of Cooling References Fab Flow

Duct Incorporated Sizing information

Pipe Size Cfm Chart

Compressed Air Pipe Size CFM Chart Garage Sanctum

Cfm Chart For Duct Sizing

Requirements for HVAC Return Air with a Duct Sizing Chart ZoobleDigital

npt pressure rating table

Compressed Air Pipe Size CFM Chart PDF Foot (Unit) Metrology

Air Flow (Cfm) Pipe Length (Feet) 25.

Web Here Are The Steps To Determine Correct Compressed Air Pipe Sizing Using The Chart.

Design Elements In A Compressed Air Pipe Network.

Web Recommended Sizes For Compressed Air Pipe Lines:

Related Post: