Conduit Bending Chart 90 Degree

Conduit Bending Chart 90 Degree - This type of bender is a step up from hand benders. Web bending a forward 90. For offsets, saddles and those special situations. Web gardner models are made of die cast aluminum and have built in spirit levels to indicate 45 and 90 degree angles. The lengths/sides of the triangle are labeled “a,” “b,” and “c”. Provided by elliott electric supply, distributor of emt benders, emt conduit, and other electrical supplies. Preparing the conduit for bending. Web when the time comes to bend the conduit (perhaps a 90° bend in each conduit), they will not align well with each other during the bend or when the bend is completed when the conduits all use a different bending radius. Web in this video i will be teaching you how to lay out, measure and bend 90 degree stub, 90 degree back to back bends. Also in the video i will educate you on how to find the gain of any bender. Web simple set radius bends: For offsets, saddles and those special situations. The red triangle represents the triangular geometry this offset creates. Web how to use an emt conduit bender to bend conduit 90 degrees, bend an offset, bend back to back 90 degree bends, bend a 3 point saddle bend, and how to straighten a bend. For offsets, saddles. Indicates the back of a 90° bend. Place a pencil mark on the conduit at the measurement where the corner should be. For offsets, saddles and those special situations. Web national electrical code or nec limits the total number of bends in one continuous run to 360 degrees or four 90 degree bends. When appearance counts, concentric bends may be. Indicates the back of a 90° bend. Web the angle d is the angle at which the conduit is bent. The “d” represents the angle at which the pipe is bent. Web most bends other than 90° can be calculated using the geometry of a triangle. When appearance counts, concentric bends may be the only way to go. Look at the head of the conduit bender. Locates the center of a saddle bend. Web the angle d is the angle at which the conduit is bent. A forward 90 is a 90 degree bend made by measuring from the front side of a pipe (front being the side you’re looking at if you’re kneeling at the half way. The “d” represents the angle at which the pipe is bent. Web for more information on using a hand bender, see my comprehensive guide to bending conduit. Web 90 degree conduit bend. These letters represent the length of each side. Step by step guide on how to bend steel conduit back of bend to back of bend (am2 am2s) gsh. These letters represent the length of each side. Master conduit bending techniques, , and calculations with our comprehensive cheat sheet. The red triangle represents the triangular geometry this offset creates. High strength ductile iron or light weight aluminum. Web a conduit bending guide for bending a 90 degree bend in electrical conduit. Web bending a forward 90. This method is also used in back to back. Step by step guide on how to bend steel (metal) conduit to 90. Web 90 degree conduit bend. For extremely tight radii, you would use a hickey bender. Work the bender onto the conduit with the conduit mark at the arrow of the bender. The national electric code (nec) specifies the minimum size for cable tray systems which includes ladder, ventilated trough, ventilated channel, solid bottom and other similar structures. Web 90 degree conduit bend. It specifically states, “there shall not be more than the equivalent of four. Step by step guide on how to bend steel (metal) conduit to 90. Step by step guide on how to bend steel conduit back of bend to back of bend (am2 am2s) gsh electrical. Web simple set radius bends: To be used with stub, offset and outer marks of saddle bends. Preparing the conduit for bending. Web how to use an emt conduit bender to bend conduit 90 degrees, bend an offset, bend back to back 90 degree bends, bend a 3 point saddle bend, and how to straighten a bend. Web a conduit bending guide for bending a 90 degree bend in electrical conduit. Start from a corner or other orienting point, then measure from. Radius and deduct figures for conduit size of conduit radius of bend deduct for 90 degrees 1/2 4 5 3/4 4 1/2 6 1 5 3/4 8 multipliers for conduit offsets degree of bend multiplier 10 degrees 6.0 22 degrees 2.6 30 degrees 2.0 45. Web to use the deduct figure, measure the distance to the far edge of the 90 and subtract the deduct figure. Place a pencil mark on the conduit at the measurement where the corner should be. Web simple set radius bends: This method is also used in back to back. Web the angle d is the angle at which the conduit is bent. The stub bend is made by bending a piece of conduit into an l shape or 90° bend by placing the free end (short end) of the tube to a predetermined length as indicated in the diagram below. Start from a corner or other orienting point, then measure from the corner to where the conduit will end (usually a converter box). The reverse method for bending a 90 is an alternative that addresses this type of situation. Work the bender onto the conduit with the conduit mark at the arrow of the bender. High strength ductile iron or light weight aluminum. This type of bender is a step up from hand benders. Reverse method to bend a 90 degree with emt. Web 90 degree conduit bend. Indicates the back of a 90° bend. To be used with stub, offset and outer marks of saddle bends.

Nec Conduit Bend Radius Chart In 2023 What You Need To Know

Conduit Bending Radius Chart Ofertasvuelo

EMT Conduit Bending Guide Elliott Electric Supply PDF

Bending Conduit Orange County

Nec Conduit Bend Radius Chart In 2023 What You Need To Know

How To Bend Conduit change comin

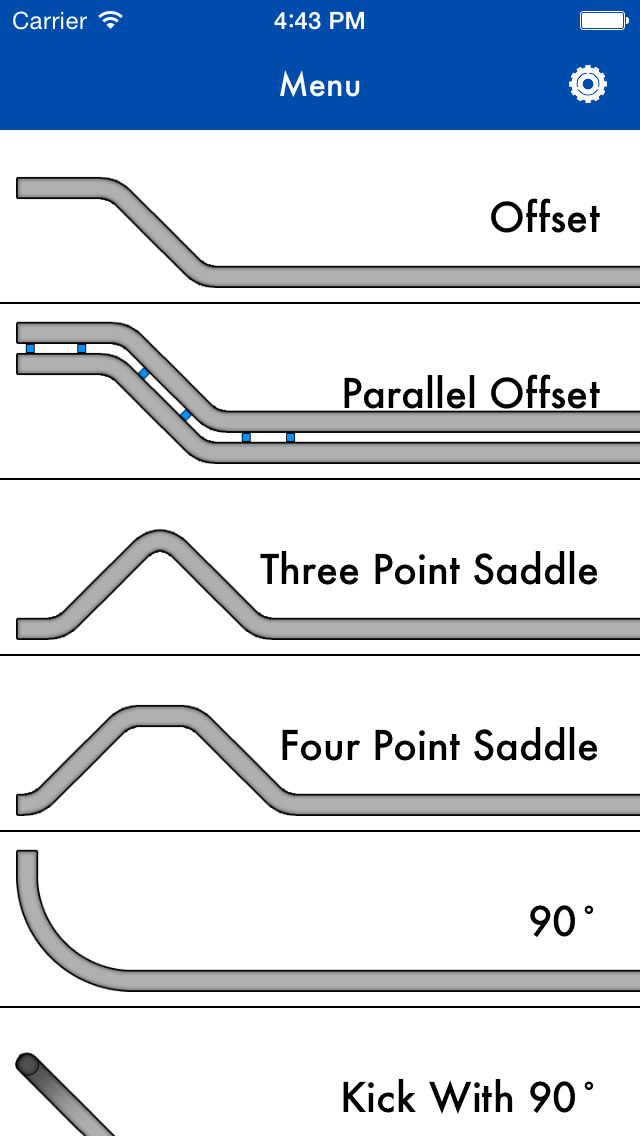

iPhone iPad

.png)

Conduit Bending Cheat Sheet ubicaciondepersonas.cdmx.gob.mx

Electrical Conduit Math Math Encounters Blog

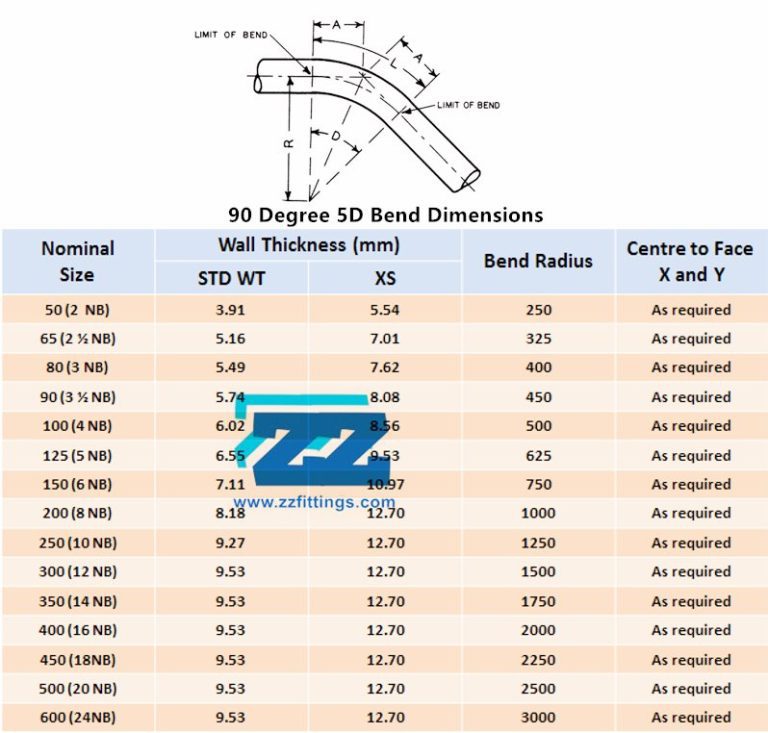

5D Bend Steel Pipe Elbow & Bend 3D / 6D / 7D / 8D / 9D / 10D ZIZI

One Of The Remaining Angles Of The Triangle Is Always 90 Degrees, While The Third Angle Always Depends On The First, Being 90 Degrees Minus Angle D.

Locates The Center Of A Saddle Bend.

Step By Step Guide On How To Bend Steel (Metal) Conduit To 90.

Mark The Stub Height That You Calculated In Step 2 From The “Up” Free End Of The Conduit.

Related Post: