Cone Temp Chart

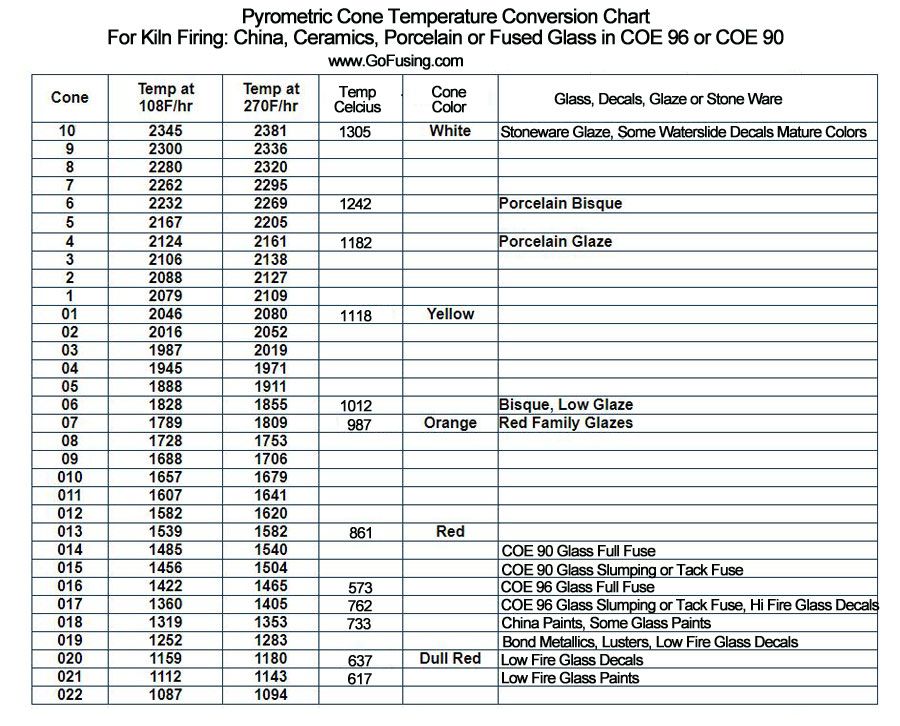

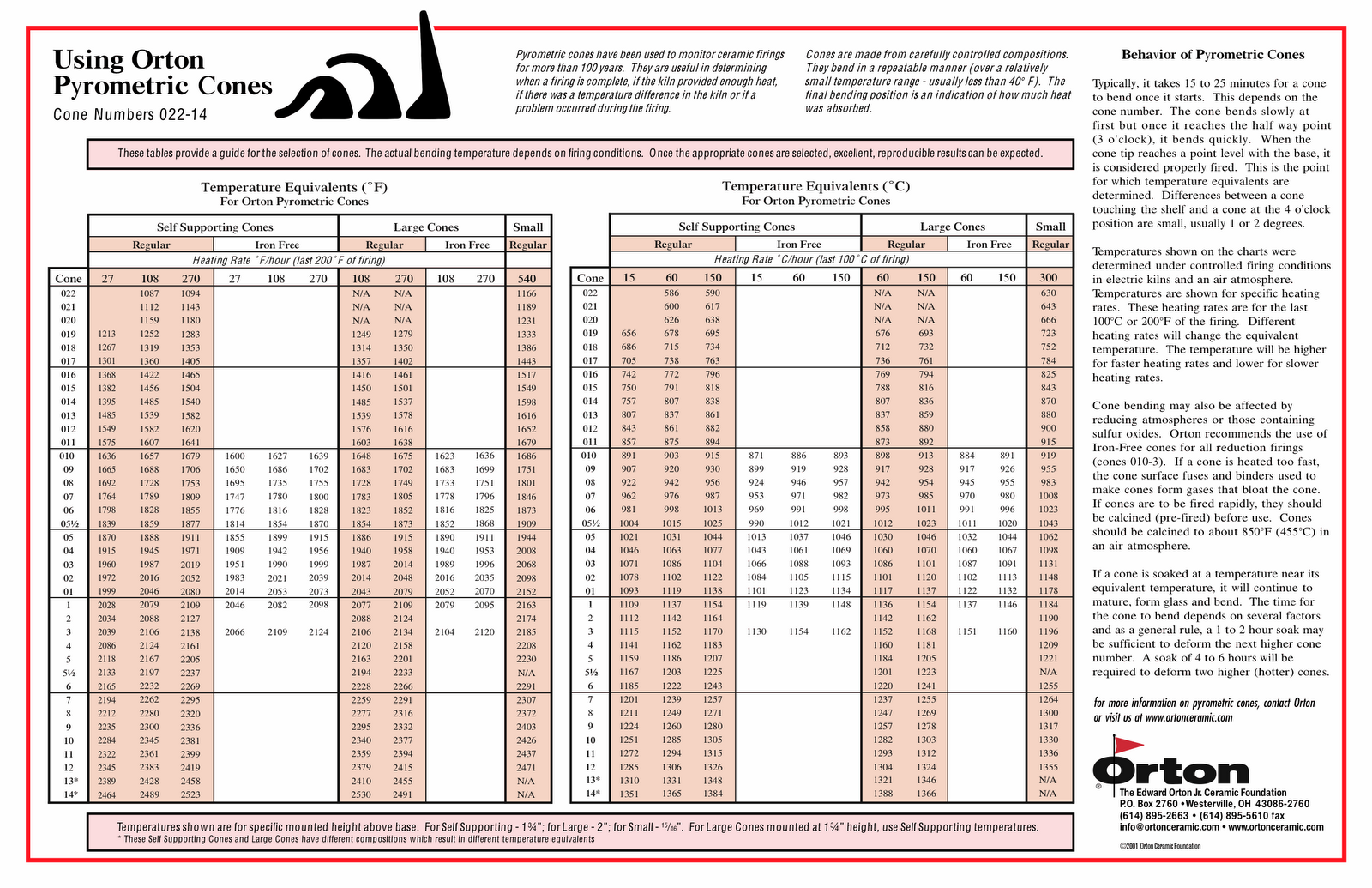

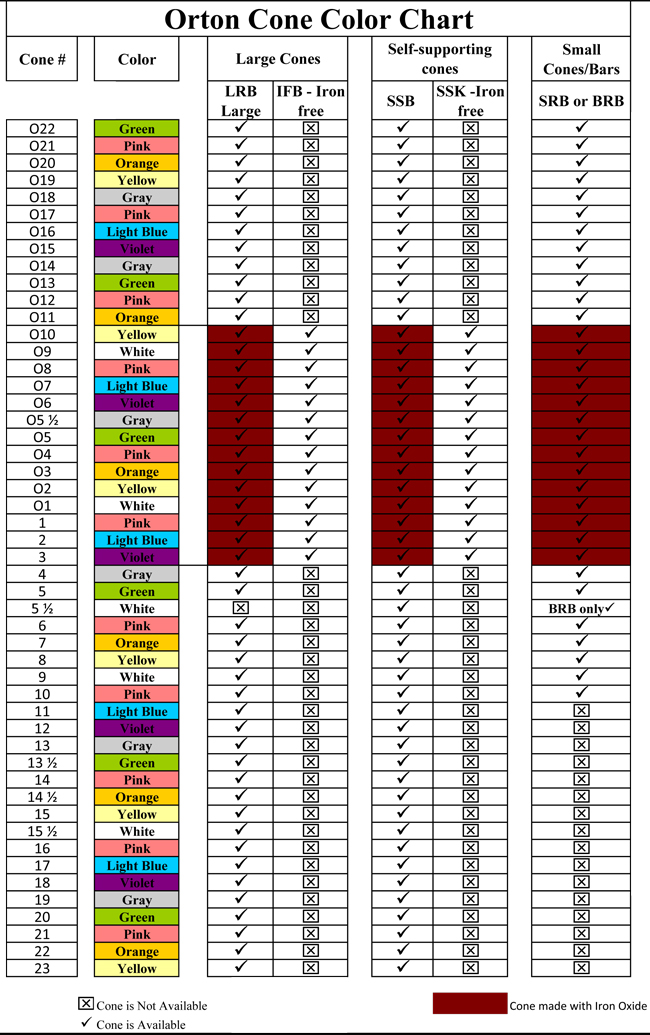

Cone Temp Chart - They are useful in determining when a firing is complete, if the kiln provided enough heat, if there was a temperature difference in the kiln or if a problem occured during the firing. This ensures that time is taken into account when calculating when the kiln shuts off. Web all of our resources for orton's pyrometric cones. Web with a cone chart, you can simply convert the cone number to a temperature in fahrenheit or celsius. This is because they contain a lot of iron. If you go slower, or hold to long at that temperature, the ware will be overfired. Stoneware glaze, *some decals fire to cone 10: Web cones should be calcined to about 850°f (455°c) in an air atmosphere. Once the appropriate cones are s elected, excellent, reproducible results can be expected. As discussed above, the equivalent cone temperature depends upon how fast one gets to it. Web differences between a cone touching the shelf and a cone at the 4 o’clock position are small, usually 1 or 2 degrees. Web generate cone temperature chart and see the conversion between kiln cones in fahrenheit and celsius based on selected heat rate increase. Temperatures shown on the charts were determined under controlled firing conditions in electric kilns and. Very low kiln cone temperature ranges. This is because they contain a lot of iron. As discussed above, the equivalent cone temperature depends upon how fast one gets to it. In other words, during the first 1500 degrees of firing (fahrenheit), how fast you fire won't affect the end temperature very much. Web use our kiln fire temperature chart to. Once the appropriate cones are selected, excellent, reproducible results can be expected. This is a table describing cone temperatures in celsius. If you go slower, or hold to long at that temperature, the ware will be overfired. October 15, 2021 by ed shears. What are the different cones used in pottery? What are the different cones used in pottery? Web the following link contains a chart of temperatures assuming a certain temperature rise. Partial cone temperature chart for large cones (fahrenheit) As discussed above, the equivalent cone temperature depends upon how fast one gets to it. For more than a century, pyrometric cones or pyrometric devices have been used to monitor. In other words, during the first 1500 degrees of firing (fahrenheit), how fast you fire won't affect the end temperature very much. Web utilize the orton cone temperature equivalents chart to select the correct cone numbers you will need. Web cone temperature conversion chart: Temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an. If you go slower, or hold to long at that temperature, the ware will be overfired. Partial cone temperature chart for large cones (fahrenheit) This is a table describing cone temperatures in celsius. What are the different cones used in pottery? This range is most commonly used in firing enamels, decals, and overglaze decorations. Web pyrometric cones are designed to melt at certain temperatures in a kiln. What does a cone do in a kiln? Web cone temperature conversion chart: You need to gently separate them by snapping the block in two. A digital pyrometer can give an accurate temperature, but pyrometric cones are useful for determining how the firing went for your ceramic. Web please note that the cone chart gives 3 different temperatures for each cone number. The actual bending temperature depends on firing conditions. October 15, 2021 by ed shears. A digital pyrometer can give an accurate temperature, but pyrometric cones are useful for determining how the firing went for your ceramic ware, and they can b If you go faster,. If you go slower, or hold to long at that temperature, the ware will be overfired. During the last 200 °f of the firing. October 15, 2021 by ed shears. This ensures that time is taken into account when calculating when the kiln shuts off. Web cones should be calcined to about 850°f (455°c) in an air atmosphere. This is a table describing cone temperatures in celsius. When you buy them they are joined together in blocks of two. The first chart here is in fahrenheit, the second is in celcius. Partial cone temperature chart for large cones (fahrenheit) This range is most commonly used in firing enamels, decals, and overglaze decorations. October 15, 2021 by ed shears. Cones indicate whether the ware received an adequate amount of heatwork to properly mature the clay or glaze. Web cones are made from carefully controlled compositions. If a cone is soaked at a temperature near its equivalent temperature, it will continue to mature, form glass and bend. A digital pyrometer can give an accurate temperature, but pyrometric cones are useful for determining how the firing went for your ceramic ware, and they can b The time for the cone to bend depends on several factors and as a general rule, a 1 to 2 hour soak may be sufficient to deform the next higher cone number. What does a cone do in a kiln? This range is most commonly used in firing enamels, decals, and overglaze decorations. The final bending position is an indication of how much heat was absorbed. Web differences between a cone touching the shelf and a cone at the 4 o’clock position are small, usually 1 or 2 degrees. Web utilize the orton cone temperature equivalents chart to select the correct cone numbers you will need. The actual bending temperature depends on firing conditions. Temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. Web with a cone chart, you can simply convert the cone number to a temperature in fahrenheit or celsius. Temperatures are shown for specific heating rates. If you go slower, or hold to long at that temperature, the ware will be overfired.

Cone 6 Temperature Chart

1000+ images about Kiln knowledge on Pinterest Design files, Sodas

Kiln Cone Temp Chart A Visual Reference of Charts Chart Master

Ceramic Curiosity Cones

Orton Cone Chart Cone Temperature Chart

What is a Cone? A Guide to Pyrometric Cones and Kilns Soul Ceramics

Pyrometric Cone Chart for Kiln Firing

Pyrometric Cone Temperature Conversion Chart Pottery

Cone 5 Temp

Orton Cone Chart Fahrenheit 2019 in 2020 Cones, Cone, Orton

They Measure “Heat Work” During A Firing, Or Time Plus Temperature.

Web Please Note That The Cone Chart Gives 3 Different Temperatures For Each Cone Number.

Once The Appropriate Cones Are Selected, Excellent, Reproducible Results Can Be Expected.

When You Buy Them They Are Joined Together In Blocks Of Two.

Related Post: