Die Size Chart

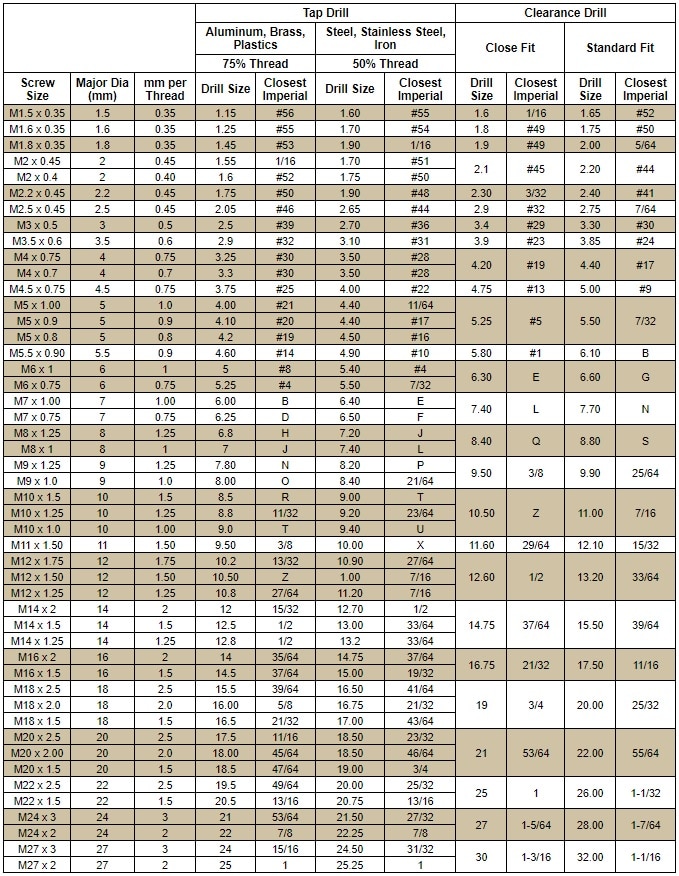

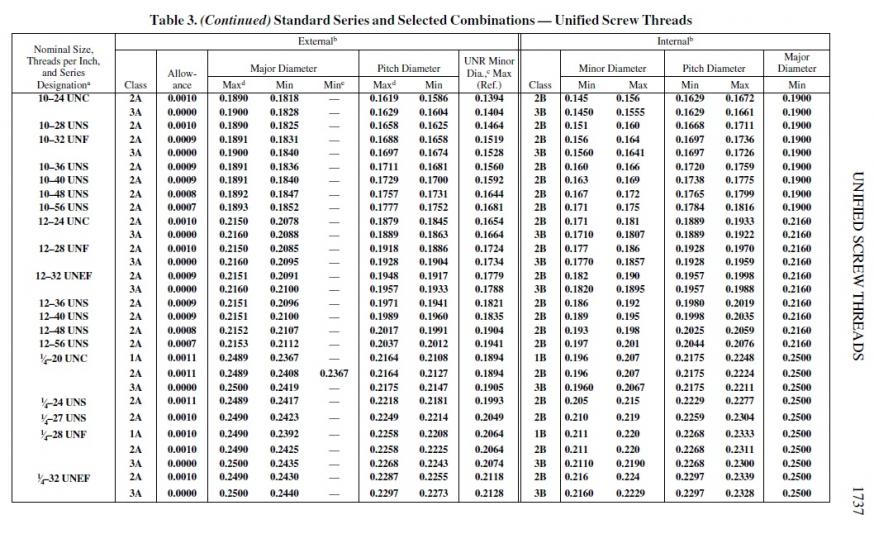

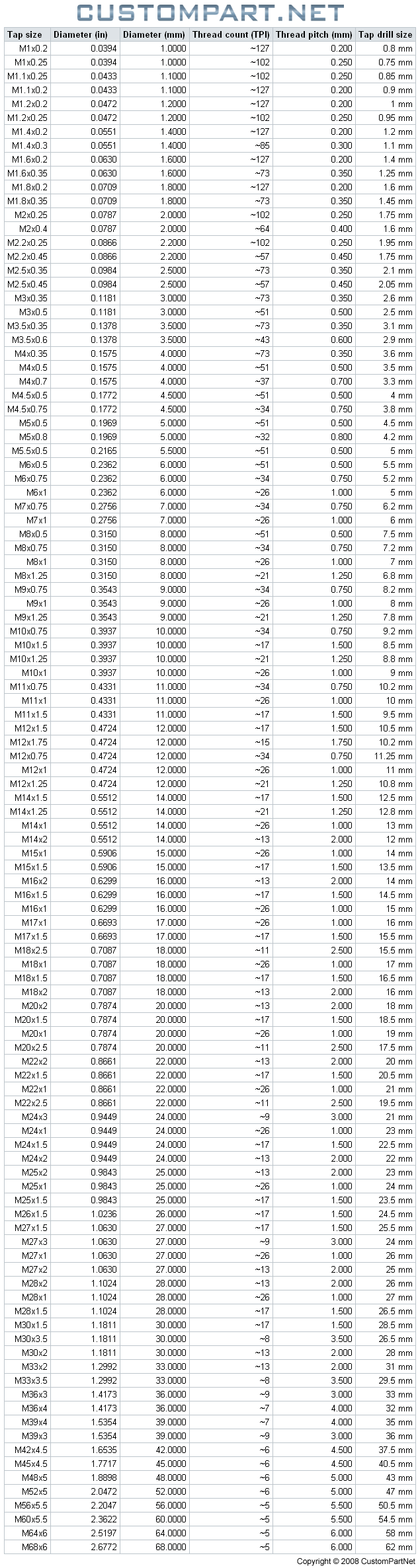

Die Size Chart - Just find the thread on the chart and go by the major diameter. Wiremike™ tooling installation system chart. It is a visual reference guide that metalworkers consult to ensure accurate and precise bends in the fabrication process. Web for more information on sizes and drilling holes for tapping a thread, see our tap drill size chart. Compatible with cordless and small electric saws. Die blank size is the major diameter less 10% of the pitch. Npt tap & die chart drill this hole size In contrast, the metric system showcases the distance between two threads in mm units. Below are the various standards that taps, dies, and the different related tools need to abide by. In stock and ready to ship. Web the sae (standard) system measures the external or internal threads of a tap/die (the thread pitch) by a unit named tpi (threads per inch). This is about the same as common bolts. It is a visual reference guide that metalworkers consult to ensure accurate and precise bends in the fabrication process. Web dies are 13/16 outside diameter and are. It is a visual reference guide that metalworkers consult to ensure accurate and precise bends in the fabrication process. Just find the thread on the chart and go by the major diameter. Web a die chart is a valuable tool used in the metalworking industry to determine the appropriate die size and angle for bending sheet metal using a press. Use our table of contents to navigate between the respective standards. Web the size rod you will need is the major diameter of the thread you will be cutting with the die. In contrast, the metric system showcases the distance between two threads in mm units. Web imperialsupplies.com tap & die chart tap & die chart drill this hole size. It is a visual reference guide that metalworkers consult to ensure accurate and precise bends in the fabrication process. Web for more information on sizes and drilling holes for tapping a thread, see our tap drill size chart. Web the size rod you will need is the major diameter of the thread you will be cutting with the die. Just. It is a visual reference guide that metalworkers consult to ensure accurate and precise bends in the fabrication process. Web choose from our selection of metric dies in a wide range of styles and sizes. Web a die chart is a valuable tool used in the metalworking industry to determine the appropriate die size and angle for bending sheet metal. Web for more information on sizes and drilling holes for tapping a thread, see our tap drill size chart. Wiremike™ tooling installation system chart. Web dies are 13/16 outside diameter and are adjustable for thread fit allowance. Web the size rod you will need is the major diameter of the thread you will be cutting with the die. Compatible with. Web for more information on sizes and drilling holes for tapping a thread, see our tap drill size chart. Npt tap & die chart drill this hole size Web the size rod you will need is the major diameter of the thread you will be cutting with the die. Web imperialsupplies.com tap & die chart tap & die chart drill. Just find the thread on the chart and go by the major diameter. Web the sae (standard) system measures the external or internal threads of a tap/die (the thread pitch) by a unit named tpi (threads per inch). Wiremike™ tooling installation system chart. Web choose from our selection of metric dies in a wide range of styles and sizes. Web. It is a visual reference guide that metalworkers consult to ensure accurate and precise bends in the fabrication process. Die blank size is the major diameter less 10% of the pitch. Web choose from our selection of metric dies in a wide range of styles and sizes. In contrast, the metric system showcases the distance between two threads in mm. Web for more information on sizes and drilling holes for tapping a thread, see our tap drill size chart. Die blank size is the major diameter less 10% of the pitch. Npt tap & die chart drill this hole size A tap drill chart determines what size hole to drill before tapping. Web dies are 13/16 outside diameter and are. Compatible with cordless and small electric saws. Wiremike™ tooling installation system chart. Web imperialsupplies.com tap & die chart tap & die chart drill this hole size drill this hole size has universal knockout to fit most saws. You’ll find plug taps, taper taps, and bottom taps in both systems. Web the size rod you will need is the major diameter of the thread you will be cutting with the die. Below are the various standards that taps, dies, and the different related tools need to abide by. In contrast, the metric system showcases the distance between two threads in mm units. Web a die chart is a valuable tool used in the metalworking industry to determine the appropriate die size and angle for bending sheet metal using a press brake. Web the sae (standard) system measures the external or internal threads of a tap/die (the thread pitch) by a unit named tpi (threads per inch). Web choose from our selection of metric dies in a wide range of styles and sizes. In stock and ready to ship. This is about the same as common bolts. Use our table of contents to navigate between the respective standards. Web dies are 13/16 outside diameter and are adjustable for thread fit allowance. Web for more information on sizes and drilling holes for tapping a thread, see our tap drill size chart. Die blank size is the major diameter less 10% of the pitch.

Metric Tap And Die Chart

Veracious Crimping Dies Chart Cable Lugs Selection Chart Crimping Die

Hydraulic Crimp Die Size Chart vlr.eng.br

Tap and Die sizes

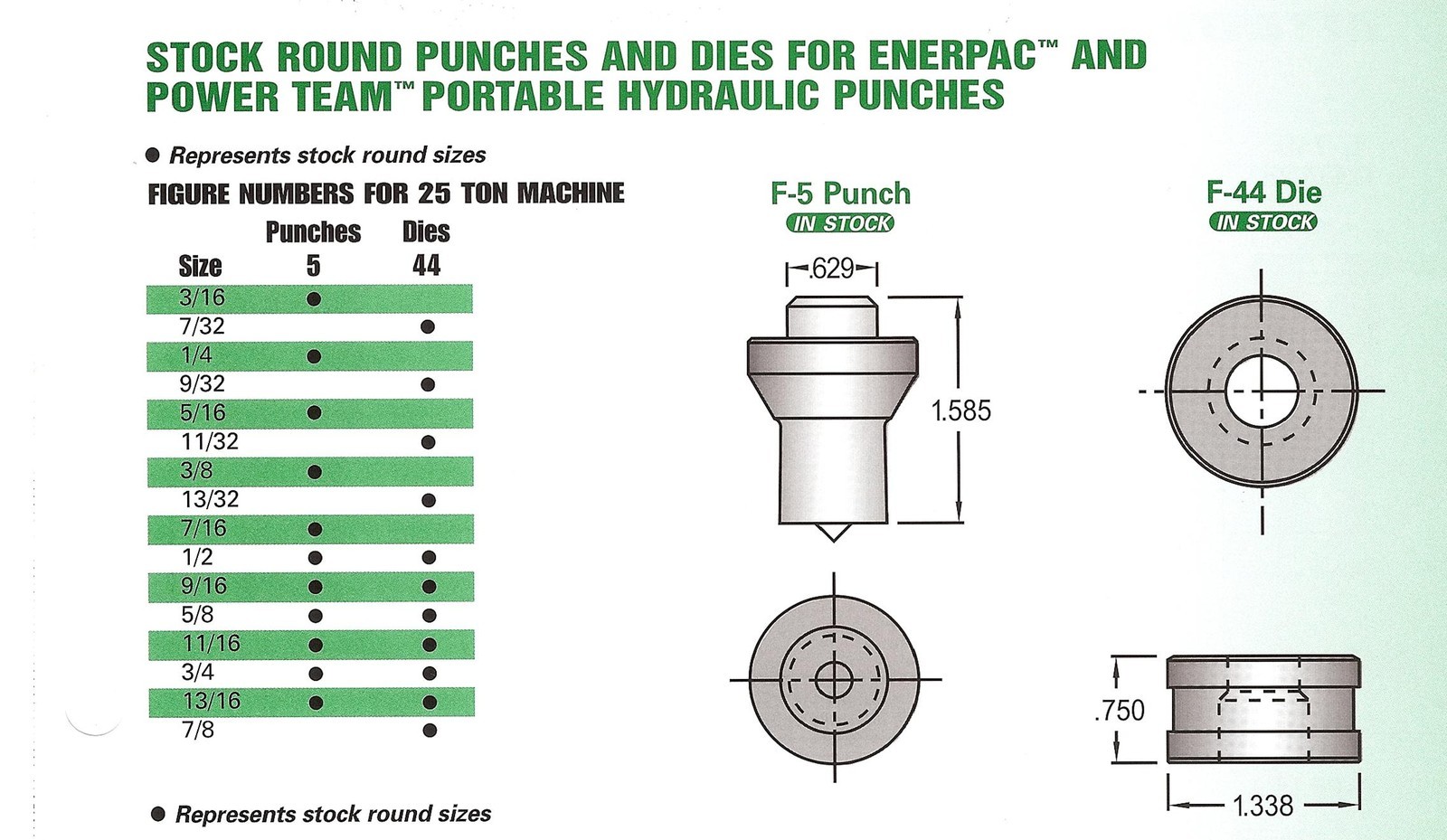

Punch And Die Size Chart ubicaciondepersonas.cdmx.gob.mx

Tap Size Chart Machining

9697822 Crimper and associated dies for size10mm² 185mm

301 Moved Permanently

Cleveland Punch and Die Company Blog Page Remember to Check Your

Metric tap and die chart Nuts n Bolts n Stuff Pinterest Taps and

Just Find The Thread On The Chart And Go By The Major Diameter.

Npt Tap & Die Chart Drill This Hole Size

A Tap Drill Chart Determines What Size Hole To Drill Before Tapping.

It Is A Visual Reference Guide That Metalworkers Consult To Ensure Accurate And Precise Bends In The Fabrication Process.

Related Post: