Electrical Lug Torque Specs Chart

Electrical Lug Torque Specs Chart - Web result table i.1 tightening torque for screws *for proper termination of conductors, it is very important that field connections be properly tightened. Tighten the stud mounting connector fully onto stud. Web result cable lug torques | information by electrical professionals for electrical professionals. Operating mechanisms and disconnect switches. Hello i was wondering if anybody could explain to me the reason or importance of torque specs when tightening cable lugs? An approved means shall be used to achieve the indicated torque value. Tightening torque values for terminal connections shall be as indicated on equipment or in installation instructions provided by the manufacturer. A 1/4 drive may not withstand the torque required for the 3000a lugs. That's listed on the enclosure,. Web result run to min. You can buy the allen wrenches with the driver attached, but the ones that i've seen have a 3/8 drive, plus i like to make my own tools if i can. Customers need to know torque spec for wire binding screw and lug retaining nut. (.102) 165 ksa4.81 1.38.62 #4 str. I found on the manufacturer site installation torque but. Web result what are the lug torque specs for 9422tf1. Tightening torque values for ilsco sockethead screw connectors. Does it depend on the wire size and material or the torque depends on the bolt size? What is the torque specs of these lugs? Web result what to do. To secure lugs to bus. Web result what to do. Web result run to min. Control and signal circuits may require different torque values, and the manufacturer should be contacted for guidance. Web result 2020 code language: Tightening torque in inch pounds. Web result what to do. What is the torque specs of these lugs? To secure lugs to bus. You can buy the allen wrenches with the driver attached, but the ones that i've seen have a 3/8 drive, plus i like to make my own tools if i can. Web result what are the lug torque specs for 9422tf1. Web result table i.1 tightening torque for screws *for proper termination of conductors, it is very important that field connections be properly tightened. Web result recommended maximum bolt loads and torque values (metric coarsethreads) 3.6 5.6 6.9 8.8 10.9 12.9 a/f mm newtons n.m newtons n.m newtons n.m newtons n.m. Does it depend on the wire size and material or the torque depends on the bolt size? Is that for the mounting bolts, the conductor lug screws, or both? That's listed on the enclosure,. A 1/4 drive may not withstand the torque required for the 3000a lugs. You can buy the allen wrenches with the driver attached, but the ones. Actually i think they want 375lbs. Web result connection torque values for main lug compartments see main lug compartment torque connection. Tighten the stud mounting connector fully onto stud. 110.14 (d) terminal connection torque. Of torque for the mains (i'm using 2 gauge to start, bringing this up as a 100a sub panel) so i bought a 250lb. Actually i think they want 375lbs. Web result what is the listed torque on the screws? Tightening torque values for ilsco sockethead screw connectors. 110.14 (d) terminal connection torque. Control and signal circuits may require different torque values, and the manufacturer should be contacted for guidance. Operating mechanisms and disconnect switches. Internal socket size across flats inches. 110.14 (d) terminal connection torque. Connection torque values for main and branch feeders. Web result tightening torque values for ilsco mechanical screw connectors. For example i am looking through. Web result what is the listed torque on the screws? Is that for the mounting bolts, the conductor lug screws, or both? An approved means shall be used to achieve the indicated torque value. A 1/4 drive may not withstand the torque required for the 3000a lugs. Does it depend on the wire size and material or the torque depends on the bolt size? Web result recommended maximum bolt loads and torque values (metric coarsethreads) 3.6 5.6 6.9 8.8 10.9 12.9 a/f mm newtons n.m newtons n.m newtons n.m newtons n.m newtons n.m newtons n.m mm 2 284 0.12 378 0.16 731 0.31 863 0.37 1216 0.52 1461 0.63 4 3 726 0.44 966 0.59 1863 1.13 2206 1.34 3109 1.88 3727 2.26 5.5 For example i am looking through. Web result dec 27, 2012. Internal socket size across flats inches. Web result necessary tools for making electrical connections: That's listed on the enclosure,. Web result what to do. Tightening torque values for ilsco sockethead screw connectors. Web result what is the listed torque on the screws? Tightening torque in inch pounds. 110.14 (d) terminal connection torque. Tightening torque in inch pounds. Web result the required torque. Is that for the mounting bolts, the conductor lug screws, or both? These lugs have torque marks and a '41' wrote on them.Electrical Lug Torque Specs Chart Eaton chartdevelopment

Nec Electrical Lug Torque Specs Chart

Electrical Lug Torque Chart

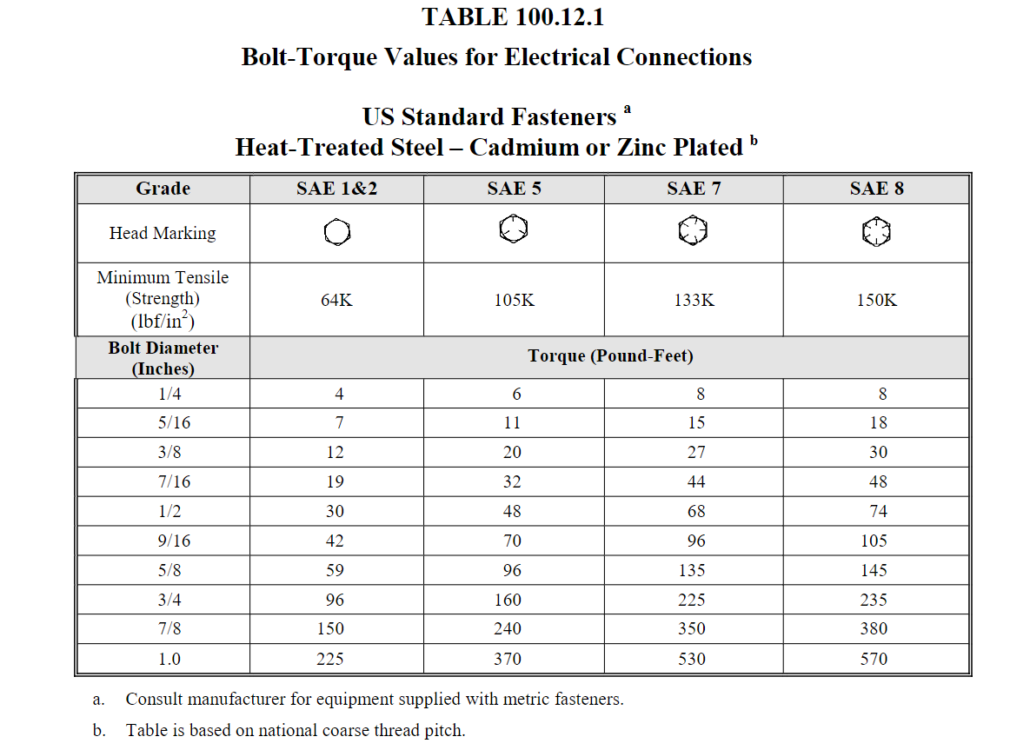

Bolt Torque Values For Electrical Connections Buist Electric

Electrical Lug Torque Specs Chart Eaton

Grade 8 Metric Bolt Torque Chart

Nec Electrical Lug Torque Specs Chart

Printable Lug Nut Torque Chart lupon.gov.ph

Torque chart av1 Electrical Connector Equipment

Square D Torque Chart

Of Torque For The Mains (I'm Using 2 Gauge To Start, Bringing This Up As A 100A Sub Panel) So I Bought A 250Lb.

An Approved Means Shall Be Used To Achieve The Indicated Torque Value.

A 1/4 Drive May Not Withstand The Torque Required For The 3000A Lugs.

Web Result Run To Min.

Related Post: