Finish Surface Chart

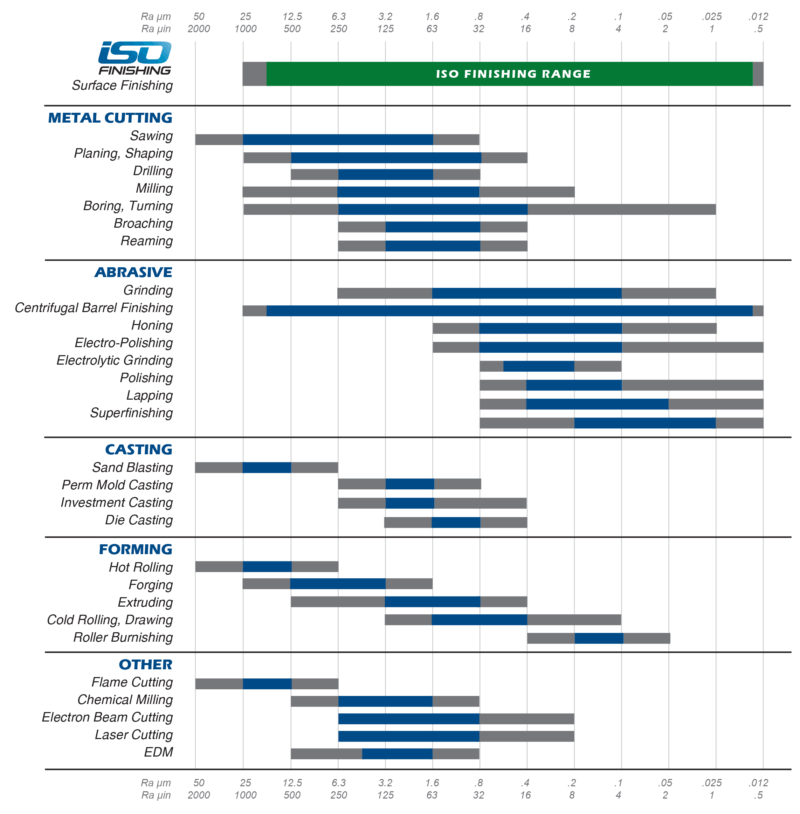

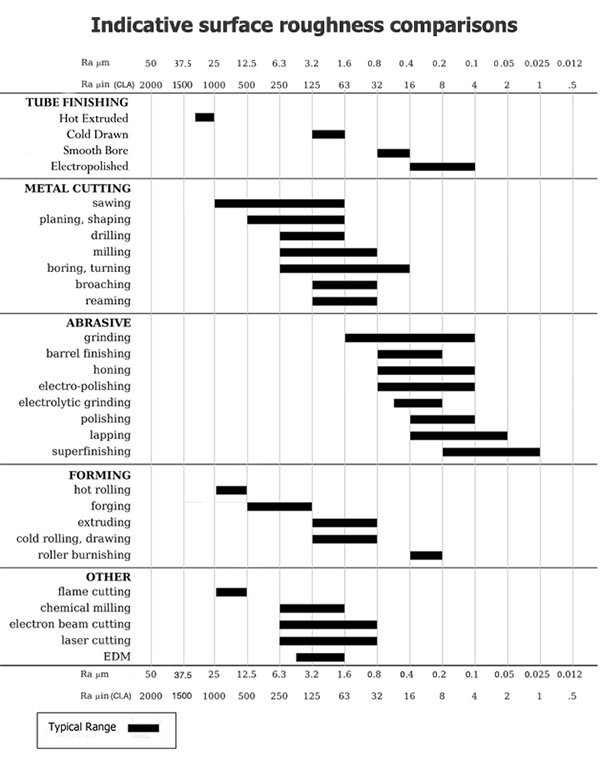

Finish Surface Chart - Check how injection moulding surface finish can be defined and used as a functional or aesthetical feature. Surface finish is a term describing the texture of the surface of a printed object. Web here’s a table with a chart demonstrating the relative surface roughness of several production processes: Whether you need to track the extreme irregularities of a surface or measure the overall average, you can compare the results with a surface finish chart. Surface finish when it is intended to include all three characteristics is often called surface texture to avoid confusion, since machinists often refer to surface roughness as surface finish. Web surface roughness chart units and abbreviations. Web the following charts and tables convert surface finish or roughness between selected industry standard units. Surface finish, when it is intended to include all three characteristics, is often called surface texture to avoid confusion, since machinists often refer to surface roughness as. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. Surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. Surface roughness chart cheat sheet. Surface finish is a term describing the texture of the surface of a printed object. For instance, when manufactured products possess smooth surfaces, they resist wear and tear better than finished parts with rougher surfaces because friction levels remain lower. Web surface finish is a measure of the overall texture of a surface that is. Web the surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. The surface finishes chart typically includes a range of surface finishes, represented by a series of numbers, letters, or symbols, that correspond to specific roughness values or other parameters. Calculate the turning surface finish. Tips for improving surface finish. Surface roughness average ra vs manufacturing process. Requirements for surface finish are frequently found on technical drawings for mechanical parts, particularly where parts fit together tightly, move against each other, or. Web you can use a surface finish chart to see which one is suited for your specific application. Web surface finish is a measure. How to choose a surface finish? Tips for improving surface finish. It is typically defined in terms of its roughness, waviness, and lay. Web here’s a table with a chart demonstrating the relative surface roughness of several production processes: Web surface finish charts. Requirements for surface finish are frequently found on technical drawings for mechanical parts, particularly where parts fit together tightly, move against each other, or. The general principle is to select a larger surface roughness value under the premise of ensuring that the technical requirements are meet. N = new iso (grade) scale numbers. Whether you need to track the extreme. The surface finishes chart typically includes a range of surface finishes, represented by a series of numbers, letters, or symbols, that correspond to specific roughness values or other parameters. Whether you need to track the extreme irregularities of a surface or measure the overall average, you can compare the results with a surface finish chart. A chart can look complex. Surface finish, when it is intended to include all three characteristics, is often called surface texture to avoid confusion, since machinists often refer to surface roughness as. Surface finishes define the final appearance of parts after machining. Web a surface finishes chart is a tool used to compare and reference the different levels of surface finish that can be achieved. Web the surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. Symbols, charts, techniques, & applications. Web you can use a surface finish chart to see which one. Web here’s a table with a chart demonstrating the relative surface roughness of several production processes: Web surface roughness chart units and abbreviations. Surface finish is a term describing the texture of the surface of a printed object. Web one type of metal surface finish chart might describe surface finish parameters — that is, the different units of measurement and. The most commonly used parameter is roughness average (ra). Web surface finish chart by machining technology. Rt = roughness, total in microns. Web surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of the surface. Web surface finish charts help to understand materials’ surface parameters effectively, be. Ra and rz roughness specification. Web surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of the surface. Surface finish can optimize a product’s performance, durability and the user experience. Web what is surface finish? Web you can use a surface finish chart to see which one is suited for your specific application. Web surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. How to choose a surface finish? Surface roughness chart cheat sheet. This will help designers and manufacturers select surface finishing techniques that are most effective for products. Surface finish, also known as surface roughness, is critical in predicting a part’s mechanical performance. Web one type of metal surface finish chart might describe surface finish parameters — that is, the different units of measurement and the arithmetic calculations used to describe surface finish. Symbols, charts, techniques, & applications. The most commonly used parameter is roughness average (ra). Therefore, different factors are affecting the characteristics of surface geometry. Web the ra surface finish chart shows the arithmetic average of surface heights measured across a surface. Web surface finish chart by machining technology.Surface Finish Chart

Surface Roughness Chart Comparison ISO Finishing

Metal Surface Roughness Chart IMAGESEE

Surface Finish Machinng Chart Pdf Surface Roughness Machining IMAGESEE

EDM Surface Finish Charts Metalworking Mechanical Engineering

Surface Finish Destiny Tool

The Basics of Surface Finish GD&T Basics

Machine Finishes Chart Open Discussion Sturgeon's House

Surface Finish Guide 5.5" x 8.5" Tool Box CNC Shop eBay in

Complete Surface Finish Chart, Symbols & Roughness Conversion Tables

Requirements For Surface Finish Are Frequently Found On Technical Drawings For Mechanical Parts, Particularly Where Parts Fit Together Tightly, Move Against Each Other, Or.

How To Measure Surface Roughness.

Web Have You Come Across A Surface Finishing Chart?

Surface Roughness Average Ra Vs Manufacturing Process.

Related Post: