Flange Bolt Torque Chart

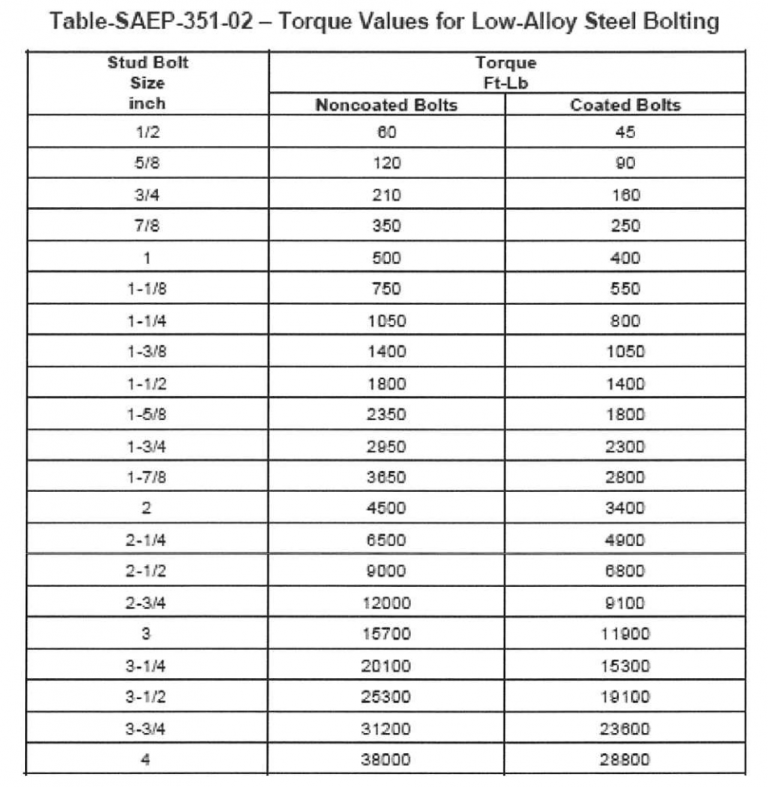

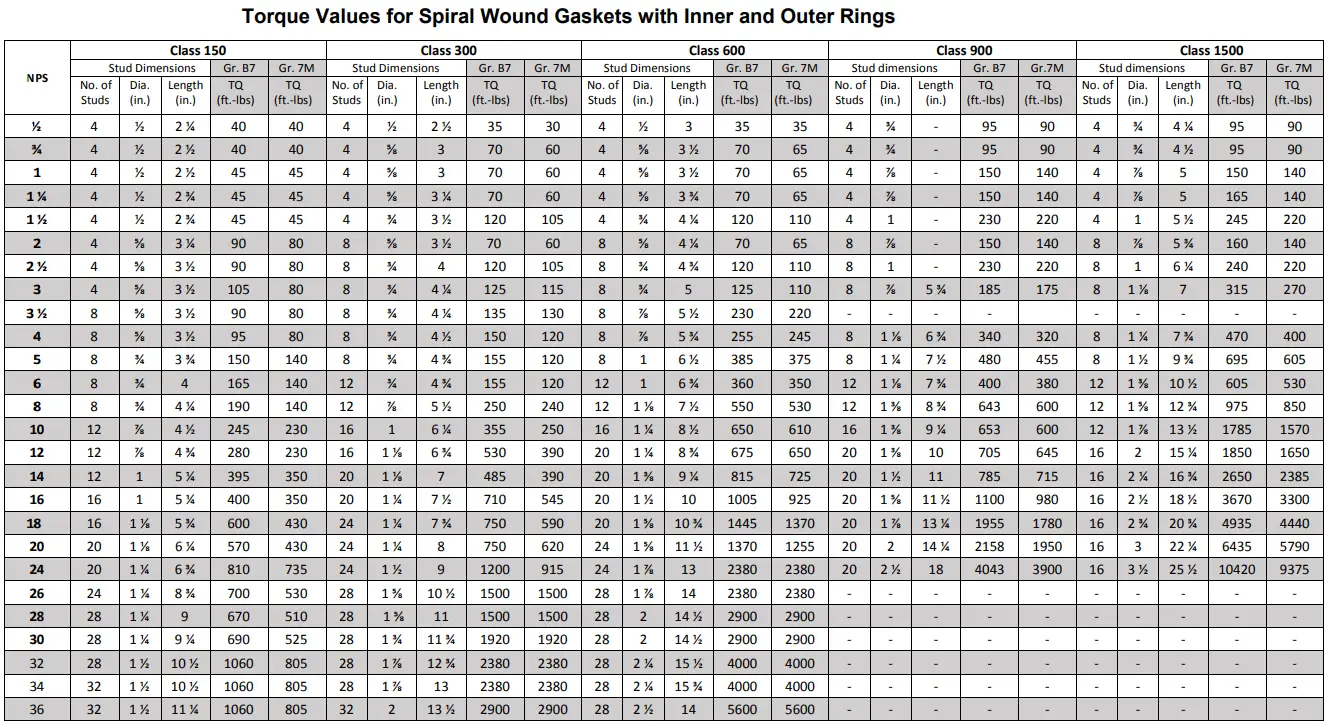

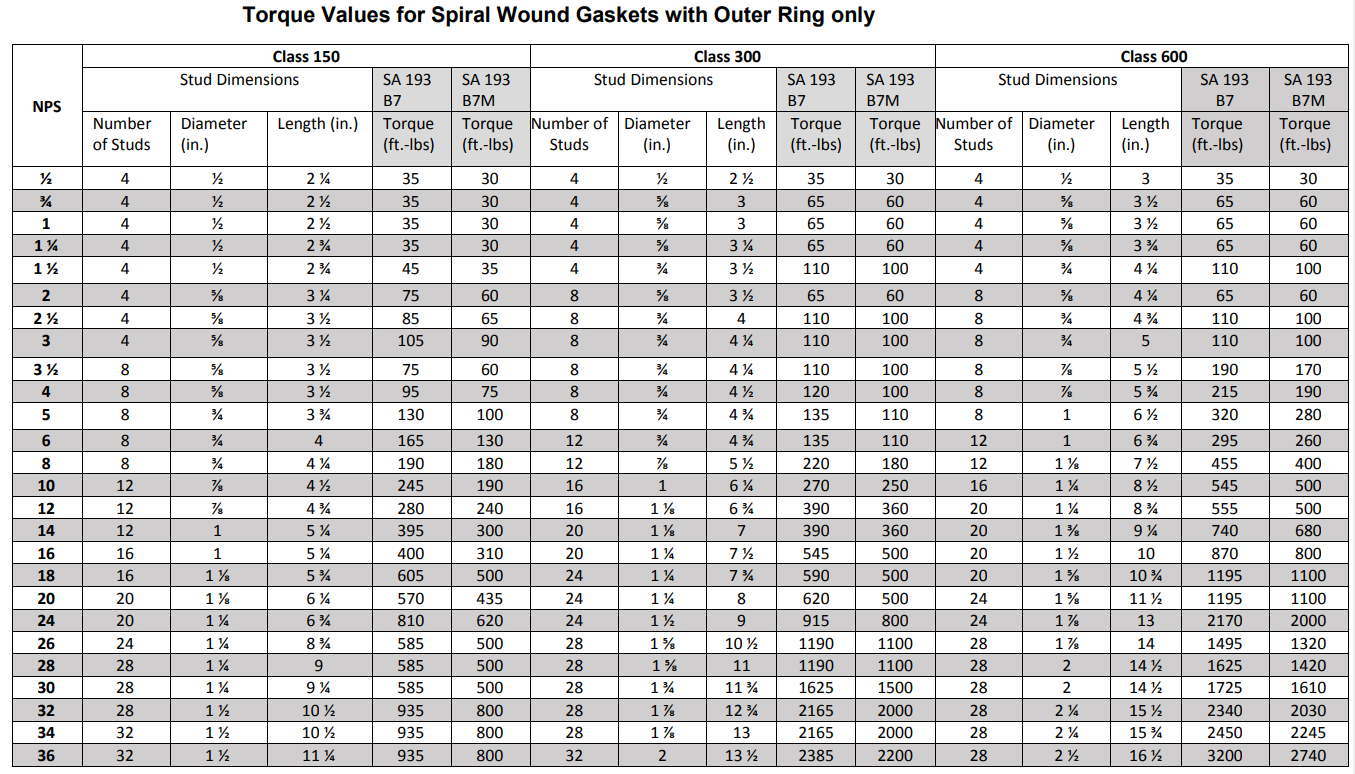

Flange Bolt Torque Chart - Web links to the flange torque charts maintained by flange bolt chart. Lbs ansi 150# flanges ansi 300# flanges ansi 600# flanges rec. Swg (type 913 and 913m) nominal diameter recommended torque flange bolt (nm) 1/2” 1/2” use class 600 flanges 3/4” 5/8” 1” 5/8” 1 1/4” 5/8” 1 1/2” 3/4” 2” 5/8” 3/4” 3” 3/4” Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Web torque for flange bolting (b7/l7 studs)* ansi / api 6a / iso 10423:2003 feb. Web with a193 grade b7 bolts for full face homogenous elastomeric gaskets note 1: The entire bolt pattern shall be tightened at least three times around the flange at. Web pipe flange bolt torque chart. In this article, you will learn about the torque sequence of pipe flanges. Even though flange blot toque calculation is possible, they are normally selected from the pipe flange bolt torque chart. Web with a193 grade b7 bolts for full face homogenous elastomeric gaskets note 1: This torque table applies for 1/16” and 1/8” thick homogenous elastomeric gaskets. Swg (type 913 and 913m) nominal diameter recommended torque flange bolt (nm) 1/2” 1/2” use class 600 flanges 3/4” 5/8” 1” 5/8” 1 1/4” 5/8” 1 1/2” 3/4” 2” 5/8” 3/4” 3” 3/4” Even. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Web pipe flange bolt torque chart. Web based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.*** rec. The pressure rating of the material may vary depending on the grade. By nominal pipe size (nps) nps 0.5 nps 0.75 nps 1 nps. 1135 psi hydro test pressure: 435 psi hydro test pressure: In this article, you will learn about the torque sequence of pipe flanges. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Web torque for flange bolting (b7/l7 studs)* ansi / api 6a / iso 10423:2003 feb. Web pipe flange bolt torque chart. Web with a193 grade b7 bolts for full face homogenous elastomeric gaskets note 1: This torque table applies for 1/16” and 1/8” thick homogenous elastomeric gaskets. 1135 psi hydro test pressure: In this article, you will learn about the torque sequence of pipe flanges. The entire bolt pattern shall be tightened at least three times around the flange at. Web based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.*** rec. The pressure rating of the material may vary depending on the grade. Web look up flange bolt sizes and torque patterns in three taps with flange bolt. In this. By nominal pipe size (nps) nps 0.5 nps 0.75 nps 1 nps 1.25 nps 1.5 nps 2 nps 2.5 nps 3 nps 3.5 nps 4 nps 5 nps 6 nps 8 nps 10 nps 12 nps 14 nps 16 nps 18 nps 20 nps 22 nps 24 nps 26 nps 28 nps 30 nps 32 nps 34 nps 36 nps. This torque table applies for 1/16” and 1/8” thick homogenous elastomeric gaskets. 1135 psi hydro test pressure: 435 psi hydro test pressure: Web torque for flange bolting (b7/l7 studs)* ansi / api 6a / iso 10423:2003 feb. Web based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.*** rec. By nominal pipe size (nps) nps 0.5 nps 0.75 nps 1 nps 1.25 nps 1.5 nps 2 nps 2.5 nps 3 nps 3.5 nps 4 nps 5 nps 6 nps 8 nps 10 nps 12 nps 14 nps 16 nps 18 nps 20 nps 22 nps 24 nps 26 nps 28 nps 30 nps 32 nps 34 nps 36 nps. Web based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.*** rec. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. The entire bolt pattern shall be tightened at least three times around the flange at. Web links to the flange torque charts maintained by flange bolt chart. Even though flange. Web with a193 grade b7 bolts for full face homogenous elastomeric gaskets note 1: Swg (type 913 and 913m) nominal diameter recommended torque flange bolt (nm) 1/2” 1/2” use class 600 flanges 3/4” 5/8” 1” 5/8” 1 1/4” 5/8” 1 1/2” 3/4” 2” 5/8” 3/4” 3” 3/4” Web look up flange bolt sizes and torque patterns in three taps with. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: Web based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.*** rec. Web pipe flange bolt torque chart. Web links to the flange torque charts maintained by flange bolt chart. The pressure rating of the material may vary depending on the grade. The entire bolt pattern shall be tightened at least three times around the flange at. Swg (type 913 and 913m) nominal diameter recommended torque flange bolt (nm) 1/2” 1/2” use class 600 flanges 3/4” 5/8” 1” 5/8” 1 1/4” 5/8” 1 1/2” 3/4” 2” 5/8” 3/4” 3” 3/4” Web torque for flange bolting (b7/l7 studs)* ansi / api 6a / iso 10423:2003 feb. 1135 psi hydro test pressure: Even though flange blot toque calculation is possible, they are normally selected from the pipe flange bolt torque chart. 435 psi hydro test pressure: Web with a193 grade b7 bolts for full face homogenous elastomeric gaskets note 1: Lbs ansi 150# flanges ansi 300# flanges ansi 600# flanges rec. By nominal pipe size (nps) nps 0.5 nps 0.75 nps 1 nps 1.25 nps 1.5 nps 2 nps 2.5 nps 3 nps 3.5 nps 4 nps 5 nps 6 nps 8 nps 10 nps 12 nps 14 nps 16 nps 18 nps 20 nps 22 nps 24 nps 26 nps 28 nps 30 nps 32 nps 34 nps 36 nps 38 nps 40 nps 42 nps 44 nps. In this article, you will learn about the torque sequence of pipe flanges.

Flange Bolt Torque Specification Chart

Bolt Torque Chart 7 Free PDF Download

Ansi Flange Bolt Chart

Buy Useful Convenient Guide Chart Comprehensive Reference

StandardFlangeSpecifications Industrial Bolting and Torque Tools

Flange Bolt Sizing Chart

Flange Bolt Torque Calculation And Pipe Flange Bolt Torque 6DA

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Bolt Chart For 150 Flanges

This Torque Table Applies For 1/16” And 1/8” Thick Homogenous Elastomeric Gaskets.

Web Look Up Flange Bolt Sizes And Torque Patterns In Three Taps With Flange Bolt.

Web A Complete Torque Tightening Sequence With Charts For Class 150 To 2500 Flanges.

Web Torque Tables For The Installation Of Flat Gaskets With Standard Asme Flanges Teadit® Material:

Related Post: