H7 Tolerance Chart

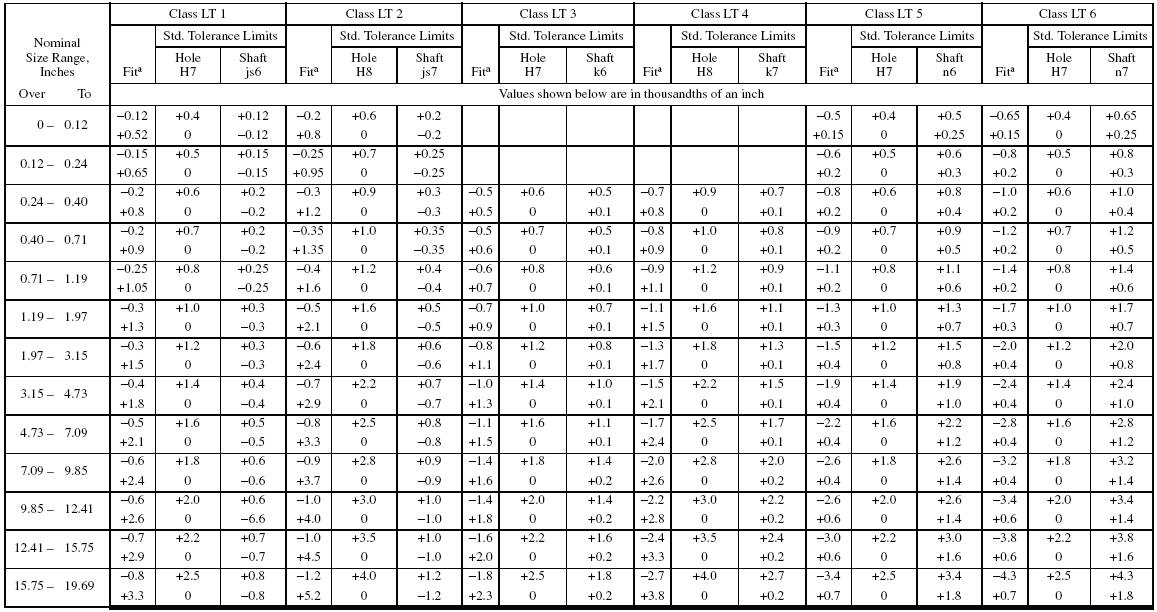

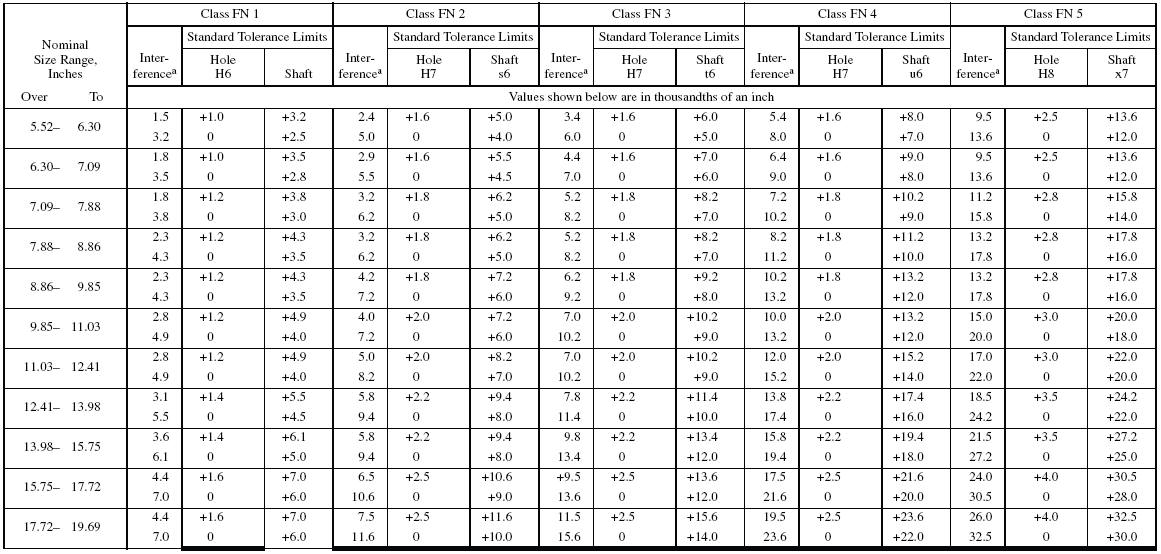

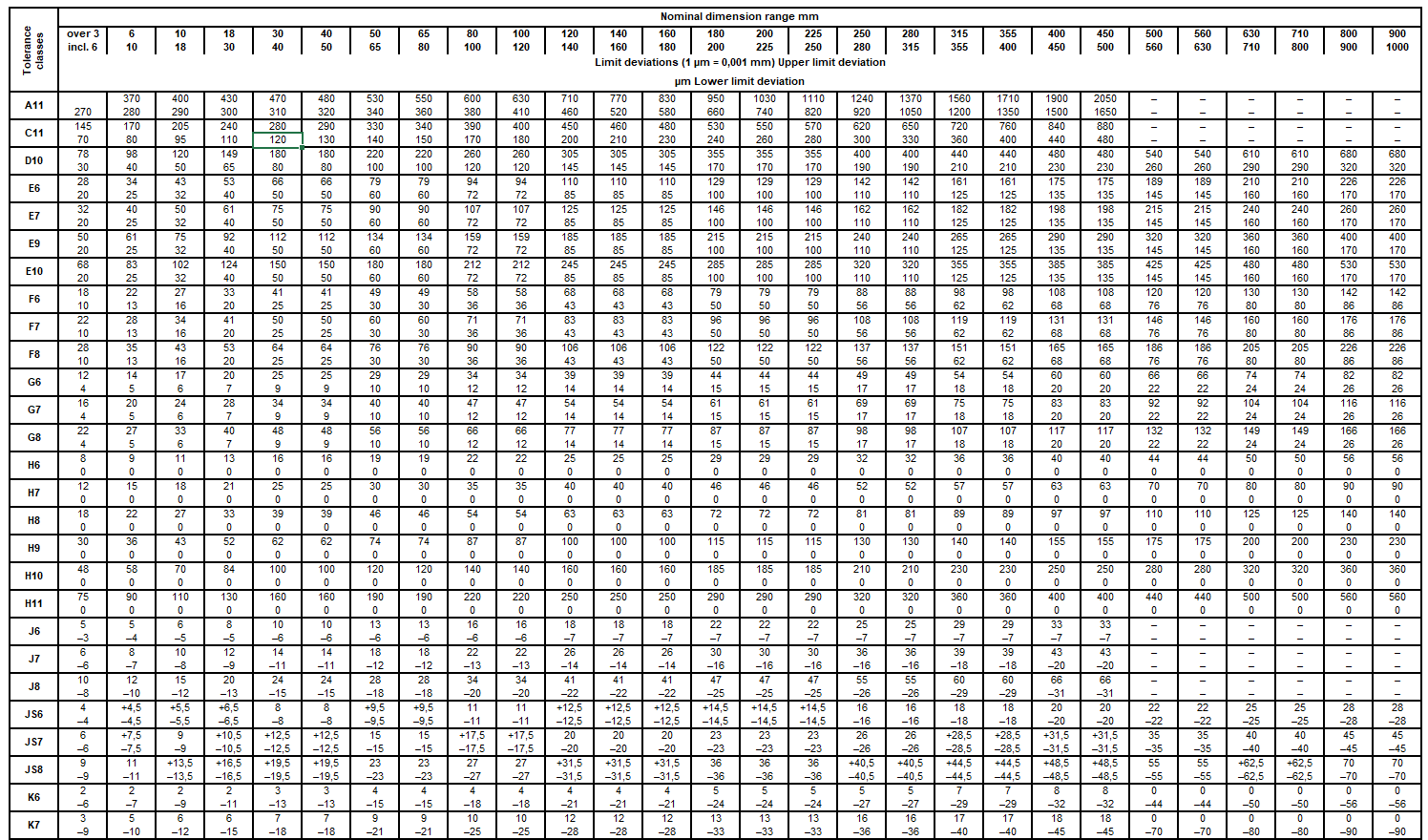

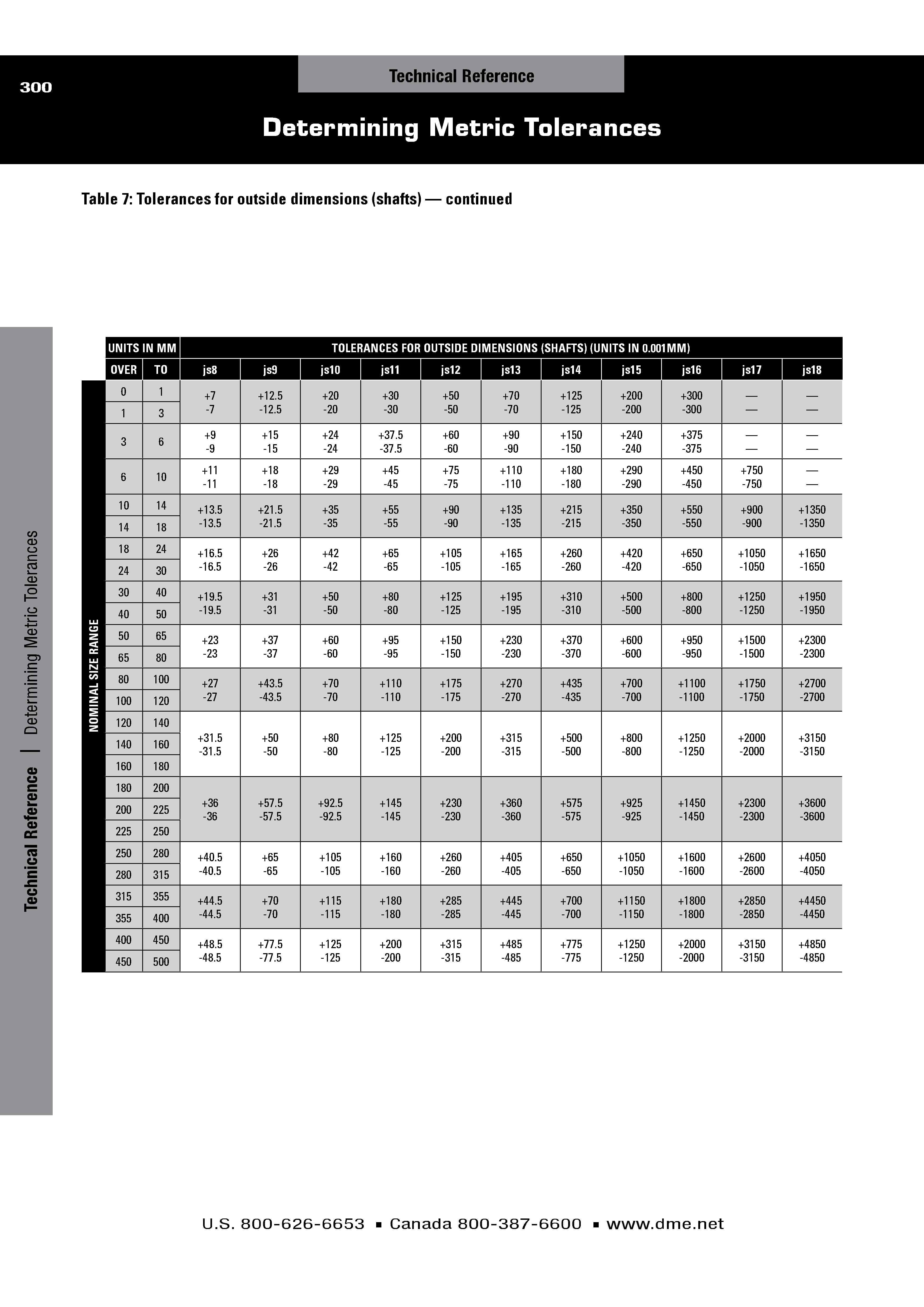

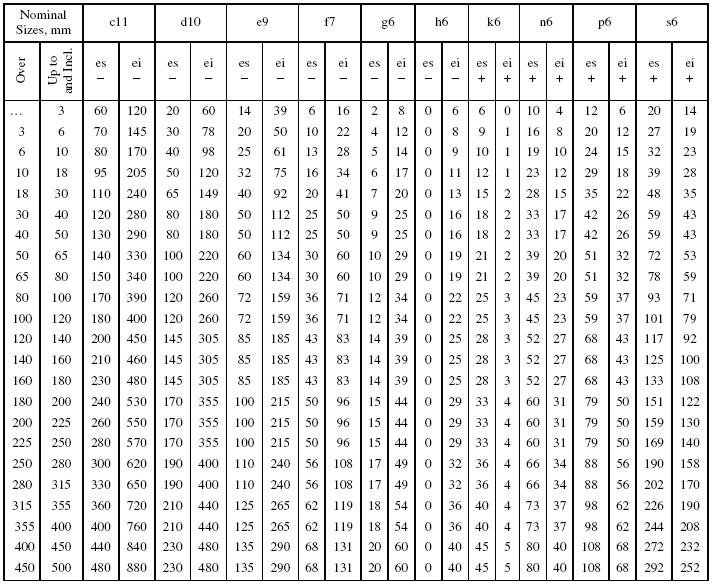

H7 Tolerance Chart - So if we have a hole with a nominal size of 25 mm and a tolerance class of h7, we will fit into the 18…30 mm basic size group. In each column, the upper figure is the upper dimensional tolerance, and the lower figure is the lower dimensional tolera hole tolerance range class nce. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. Green = prefered tolerance classes. (tighter than loose) hole based press fit: Find your data faster with our fits calculator. Parts are usually made to assemble with other ones. Web the first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. When it talks about assembly, the standards tolerances below. Iso tolerance zone calculator usage. Green = prefered tolerance classes. Find your data faster with our fits and tolerance calculator. Web from the table, we can see that the tolerance grade applies to a range of basic sizes. Tolerance deviaiton h (for shafts) the posision of h relative to the other shaft deviations. (looser than tight) shaft based press fit: Looking at the it7 tolerance grade, the chart gives an allowed variance of 0.021 mm. Web from the table, we can see that the tolerance grade applies to a range of basic sizes. Tolerance deviaiton h (for shafts) the posision of h relative to the other shaft deviations. Web table of metric hole tolerances per. Go here, for explanasions about. Web table of metric hole tolerances per. Μ m standard dimension more than not more than In each column, the upper figure is the upper dimensional tolerance, and the lower figure is the lower dimensional tolera hole tolerance range class nce. (tighter than loose) hole based press fit: So if we have a hole with a nominal size of 25. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. Go here, for explanasions about the terms hole, shaft, ei, and es. Complete charts for h7/h6 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. Web h7 h6 g7 g6 f8 f7 f6 e9. Web hole based sliding: Looking at the it7 tolerance grade, the chart gives an allowed variance of 0.021 mm. Find your data faster with our fits calculator. Web table of metric hole tolerances per. Μ m standard dimension more than not more than Web table of metric hole tolerances per. Nominal size h7 h8 h9 h11 > ≤ upper lower upper lower upper lower upper lower; The following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. Μ m standard dimension more than not more than Find your data faster with our fits calculator. Web the hole basis fits have four preferred hole tolerances (h11, h9, h8, and h7); When it talks about assembly, the standards tolerances below. Web the first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Looking. Parts are usually made to assemble with other ones. Click on to get additional tolerance options. In each column, the upper figure is the upper dimensional tolerance, and the lower figure is the lower dimensional tolera hole tolerance range class nce. So if we have a hole with a nominal size of 25 mm and a tolerance class of h7,. Web h7 h6 g7 g6 f8 f7 f6 e9 e8 e7 d10 d9 d8 c10 c9 b10 ( mm ) note: So if we have a hole with a nominal size of 25 mm and a tolerance class of h7, we will fit into the 18…30 mm basic size group. Looking at the it7 tolerance grade, the chart gives an. (looser than tight) shaft based press fit: Hole dimensional tolerances for regularly used ˜tting units: Web hole based sliding: Looking at the it7 tolerance grade, the chart gives an allowed variance of 0.021 mm. Web h7 h6 g7 g6 f8 f7 f6 e9 e8 e7 d10 d9 d8 c10 c9 b10 ( mm ) note: Green = prefered tolerance classes. Enter your desired preferred tolerance grade and the nomial size. When it talks about assembly, the standards tolerances below. Web hole based sliding: Complete charts for h7/h6 clearance fit per iso 286, including size limits for hole and shaft and clearance classification data. So if we have a hole with a nominal size of 25 mm and a tolerance class of h7, we will fit into the 18…30 mm basic size group. Web h7 h6 g7 g6 f8 f7 f6 e9 e8 e7 d10 d9 d8 c10 c9 b10 ( mm ) note: Looking at the it7 tolerance grade, the chart gives an allowed variance of 0.021 mm. Parts are usually made to assemble with other ones. Find your data faster with our fits and tolerance calculator. Μ m standard dimension more than not more than Web the hole basis fits have four preferred hole tolerances (h11, h9, h8, and h7); Tolerance deviaiton h (for shafts) the posision of h relative to the other shaft deviations. Iso tolerance zone calculator usage. Web the first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Hole dimensional tolerances for regularly used ˜tting units:

Iso 2768 hole tolerance table iespoo

Bearing Fit Tolerance Chart Metric

H7 Fit Tolerance In Mm Byggkonsult

Iso 2768 Hole Tolerance H7 policepriority

Iso 2768 hole tolerance h7 lasopaback

Holes ISO Tolerances . ISO tolerances for holes and their corresponding

Interpretation of system of Fits on engineering drawing with an example

Iso fits and tolerances chart pofepharmacy

H7 Shaft Tolerance Chart submited images.

H7 Hole Tolerance Home Interior Design

Go Here, For Explanasions About The Terms Hole, Shaft, Ei, And Es.

Nominal Size H7 H8 H9 H11 > ≤ Upper Lower Upper Lower Upper Lower Upper Lower;

Hole Based Location Transition :

Web Table Of Metric Hole Tolerances Per.

Related Post: