Haccp Flow Chart

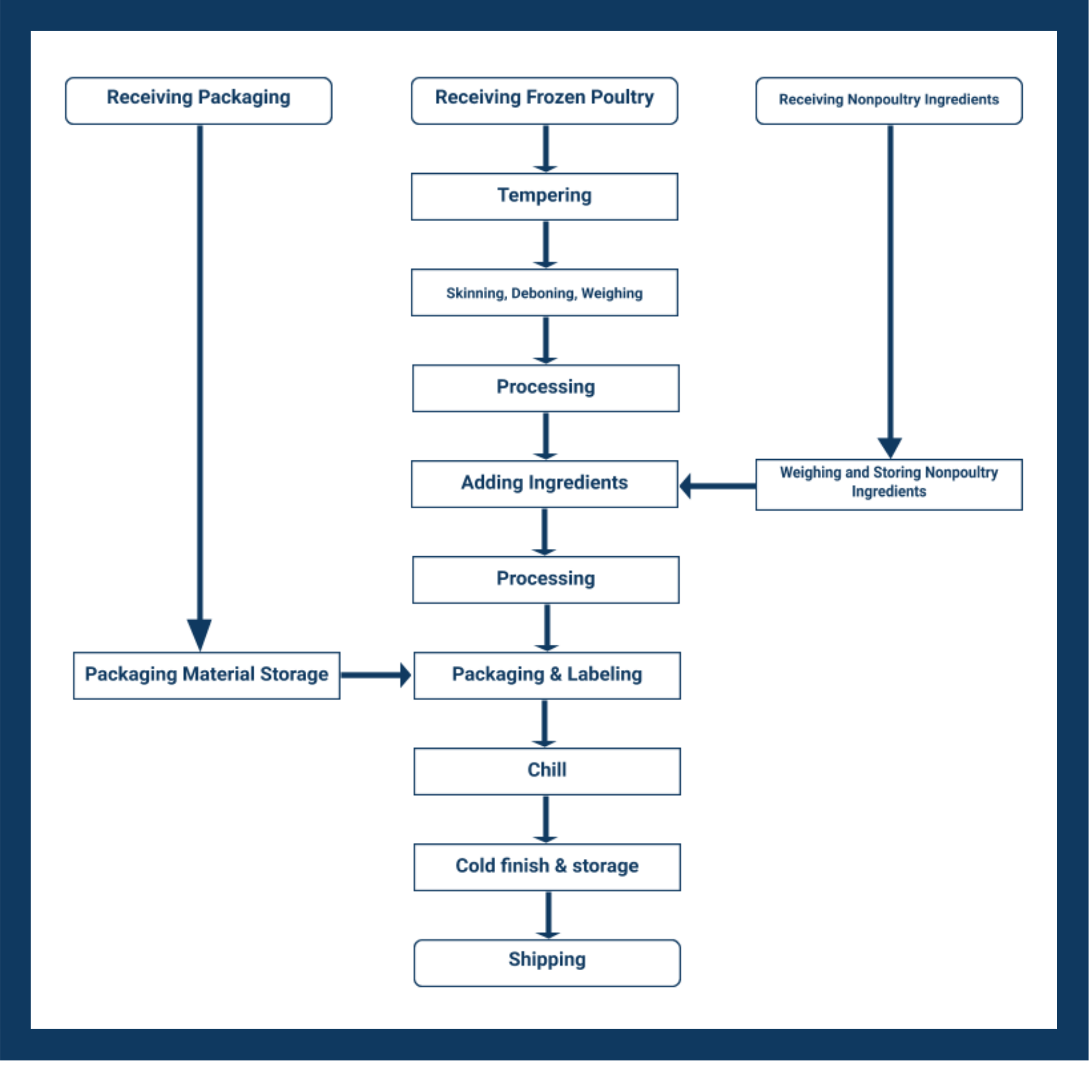

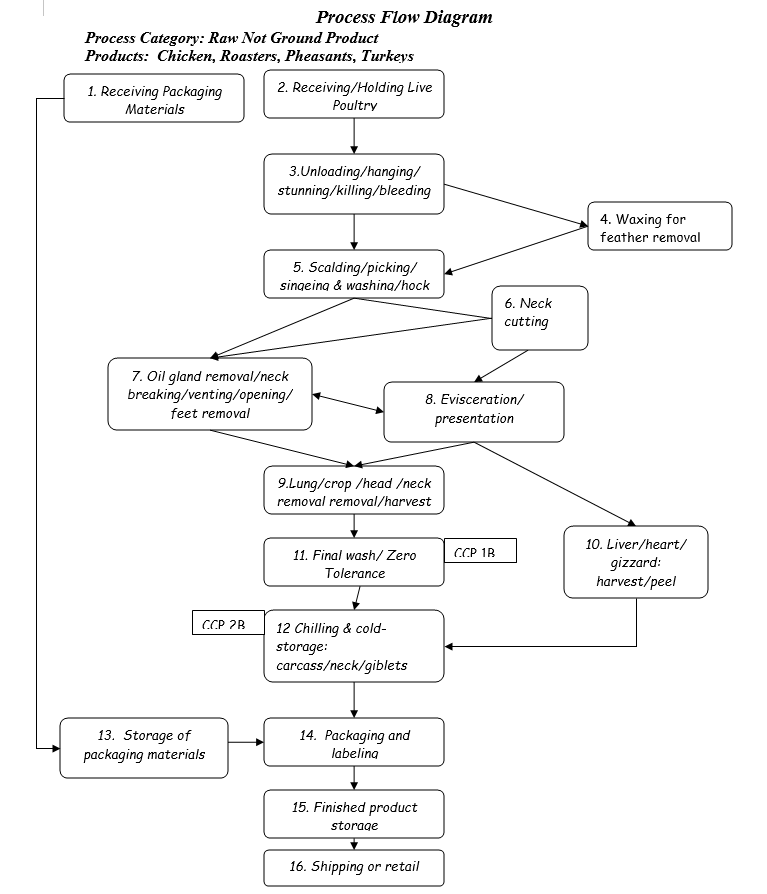

Haccp Flow Chart - Use this example haccp flow diagram to help you visualise the flow of food in your business and each step of the process. Web a haccp flow chart represents the flow of food materials in your food business starting from receiving any raw material to serving your finished products. Make an haccp food plan. Web a haccp flow chart represents the flow of food materials in your food business starting from receiving the raw materials to serving your finished products. The key steps in the process are identified, laid out step by step, and subsequently verified by the haccp team. Provides guidance and a template for you to draw your own flow diagram. Goods received template (13.23 kb) word. Web maximize the use of this template by following the points below: Contains guidance on the haccp terms used in this manual. The staff you choose for this first haccp plan step need to have technical knowledge of your food preparation or production and of the chemical, biological, and physical hazards present at your facility or at your restaurant. If you run a food business, you must have a plan based on the hazard analysis and critical control point (haccp). Depending on your process you may have many more or fewer steps or types of steps than the ones listed. Guide to compliance with the haccp concept. Goods received template (13.23 kb) word. Here, the haccp team uses the. Take or attach photos of the process. Web a haccp plan is made using a series of preliminary haccp steps including building a haccp team, describing the product and its distribution, i dentifying the product's intended use and target consumer, developing a diagram of. Firm name and location of the processor or importer; Web the flow diagram demonstrates a general. Use this example haccp flow diagram to help you visualise the flow of food in your business and each step of the process. The staff you choose for this first haccp plan step need to have technical knowledge of your food preparation or production and of the chemical, biological, and physical hazards present at your facility or at your restaurant.. Haccp food safety system requires a detailed and comprehensive food flow chart to properly identify the associated hazards in your manufacturing process. Web a haccp flow chart is a diagram of the process flow of a food operation from incoming materials to the end product. Web the simplest form of process flow diagram is linear. Make an haccp food plan.. Web maximize the use of this template by following the points below: Web a haccp flow chart represents the flow of food materials in your food business starting from receiving any raw material to serving your finished products. Determine ccp and establish its critical limits and monitoring procedures. Web a haccp flow chart represents the flow of food materials in. Web haccp is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and. Product description and signature and date (haccp plan). Web the purpose of the flow chart is for the establishment to find any places where hazards could occur. Contains guidance on the. Firm name and location of the processor or importer; Web a flow chart describing the steps of each process and product flow in the establishment shall be prepared, and the intended use or consumers of the finished product shall be identified. The food safety critical limits selected must come from scientific documents or other reliable sources. If you're creating or. Web steps in a flow process chart can include receival of raw materials, store of ingredients, preparation, cooking, cooling, packing, labelling, bulk storage and dispatch. (the flow diagram can also include steps in the food chain which come before and after the processing that occurs in the establishment.) Meaning and definition of the food hygiene concept. Web develop a flow. Product description and signature and date (haccp plan). Shows you what could go wrong at each process step and what you need to do about it. Fsis developed generic haccp models for each process category which establishments can reference when developing their. If you're creating or revising your food safety program, it helps to visualise how food moves through your. Web the flow diagram demonstrates a general production process and should be modified to reflect the processes used at the establishment. Web maximize the use of this template by following the points below: Identify potential hazards, likelihood of occurrence, its ccp (if any) and provide preventive measures. Web a haccp flow chart represents the flow of food materials in your. The key steps in the process are identified, laid out step by step, and subsequently verified by the haccp team. Goods received template (13.23 kb) word. Web a haccp flow chart represents the flow of food materials in your food business starting from receiving any raw material to serving your finished products. Web modular haccp plan diagram (32.05 kb) templates and examples of completed templates. (the flow diagram can also include steps in the food chain which come before and after the processing that occurs in the establishment.) Web the purpose of the flow chart is for the establishment to find any places where hazards could occur. Fsis developed generic haccp models for each process category which establishments can reference when developing their. Determine ccp and establish its critical limits and monitoring procedures. Web this guidebook for the preparation of haccp plans provides information that may be useful to establishments when developing plans specific to their food production processes and when implementing a food safety system. Here, the haccp team uses the product description, intended use, and primary market to develop a complete description of the production process from start to end. Web the flow diagram demonstrates a general production process and should be modified to reflect the processes used at the establishment. Web a haccp plan is made using a series of preliminary haccp steps including building a haccp team, describing the product and its distribution, i dentifying the product's intended use and target consumer, developing a diagram of. Web a flow chart describing the steps of each process and product flow in the establishment shall be prepared, and the intended use or consumers of the finished product shall be identified. Make an haccp food plan. The staff you choose for this first haccp plan step need to have technical knowledge of your food preparation or production and of the chemical, biological, and physical hazards present at your facility or at your restaurant. Firm name and location of the processor or importer;

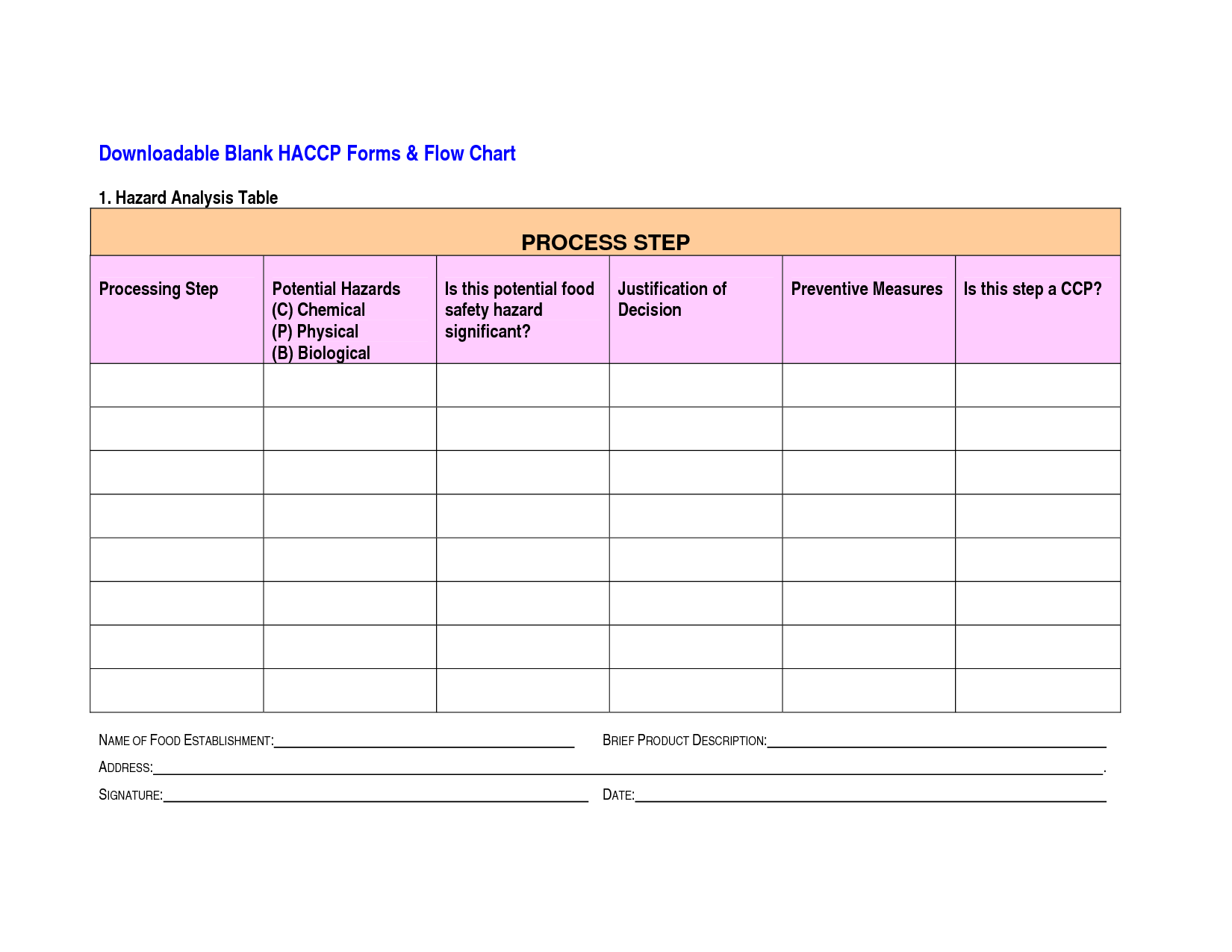

Haccp Food Safety Plan Template Luxury 28 Of Haccp Plan Template Food

6 Best Images of Blank HACCP Flow Chart Template Printable

.png?width=1920&name=HACCP (6).png)

HACCP Guide Definition, Templates, and the 7 Principles of Safe Food

Completing Your HACCP Plan Template a StepByStep Guide Safesite

![26 Fantastic Flow Chart Templates [Word, Excel, Power Point]](https://templatelab.com/wp-content/uploads/2021/08/HACCP-Flow-Chart-scaled.jpg)

26 Fantastic Flow Chart Templates [Word, Excel, Power Point]

How to Plan and Manage a Successful HACCP System Safesite

HACCP Flow Chart

Figure 1. Description of Process Flow Diagram A Model HACCP Plan for

generalized HaCCP Flow CHart Download Scientific Diagram

example robust haccp flow charts Google Search Flow chart, Flow, Chart

The Food Safety Critical Limits Selected Must Come From Scientific Documents Or Other Reliable Sources.

A Haccp Flow Chart Is Normally Constructed By A Group Commonly Known As The Haccp Team Or Food Safety Team.

The Second Step Of Your Template Requires You To Identify The Scope And The Process Or Commodity Flow.

Web Steps In A Flow Process Chart Can Include Receival Of Raw Materials, Store Of Ingredients, Preparation, Cooking, Cooling, Packing, Labelling, Bulk Storage And Dispatch.

Related Post: