K Factor Chart

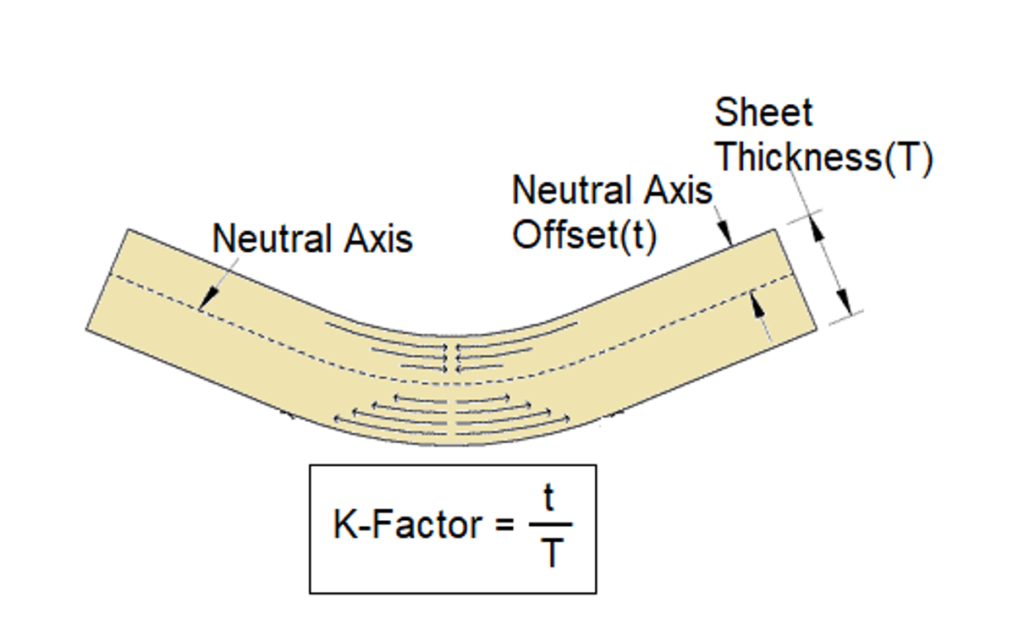

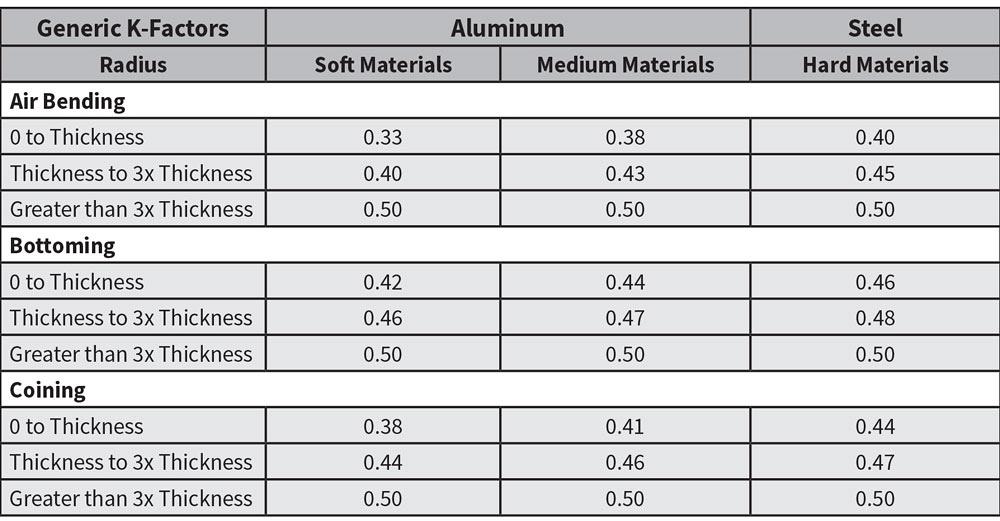

K Factor Chart - Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Soft copper or soft brass: Maybe a kraft american single? Web k factor chart. Bronze, hard bronze, cold rolled steel, spring steel, etc.: Web best way to calculate the value of k factor in sheet metal is by reverse engineering. (88.9mm) square by 0.083 in. Now, bend it evenly over the edge of the countertop. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. When you bend sheet metal, the neutral axis shifts toward the inside surface of the bend. (88.9mm) square by 0.083 in. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Maybe a kraft american single? It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. Now, bend it evenly over the edge of the countertop. Web k factor chart. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. Soft copper or soft brass: Maybe a kraft american single? When you bend sheet metal, the neutral axis shifts toward the inside surface of the bend. Bronze, hard bronze, cold rolled steel, spring steel, etc.: Maybe a kraft american single? Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Web best way to calculate the value of k factor in sheet metal is by reverse engineering. When you bend sheet metal, the neutral axis shifts toward the. When you bend sheet metal, the neutral axis shifts toward the inside surface of the bend. Web k factor chart. Soft copper or soft brass: Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Web best way to calculate the value of k factor in sheet metal is by reverse engineering. When you bend sheet metal, the neutral axis shifts toward the inside surface of the bend. Web best way to calculate the value of k factor in sheet metal is by reverse engineering. Maybe a kraft american single? It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. Bronze, hard. Web best way to calculate the value of k factor in sheet metal is by reverse engineering. Bronze, hard bronze, cold rolled steel, spring steel, etc.: Maybe a kraft american single? Now, bend it evenly over the edge of the countertop. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired. When you bend sheet metal, the neutral axis shifts toward the inside surface of the bend. Web best way to calculate the value of k factor in sheet metal is by reverse engineering. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. (88.9mm) square by 0.083 in. Now, bend. Bronze, hard bronze, cold rolled steel, spring steel, etc.: Soft copper or soft brass: Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Maybe a kraft american single? Now, bend it evenly over the edge of the countertop. (88.9mm) square by 0.083 in. Web k factor chart. Bronze, hard bronze, cold rolled steel, spring steel, etc.: Maybe a kraft american single? When you bend sheet metal, the neutral axis shifts toward the inside surface of the bend. Soft copper or soft brass: Maybe a kraft american single? It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. Bronze, hard bronze, cold rolled steel, spring steel, etc.: (88.9mm) square by 0.083 in. (88.9mm) square by 0.083 in. Web best way to calculate the value of k factor in sheet metal is by reverse engineering. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. Maybe a kraft american single? Soft copper or soft brass: Web k factor chart. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. Now, bend it evenly over the edge of the countertop.

Sheet Metal K Factor (with Calculator and Formula)

Soil series with corresponding calculated K factor values for the major

TRACE GC ULtra KFactor Quick Reference GC & GCMS Product Support

What is KFactor? Reference Chart from AGF Manufacturing

K factor in sheetmetal work. Autodesk Inventor Users GrabCAD Groups

what is the correct value of K factor in sheet metal in solidworks

What is the K factor and how do we use it in HVAC applications? HVAC

35 HYDRAULIC K FACTOR TABLE

Kfactors, Yfactors, and press brake bending precision

Flow Meter Kfactor and Calculations Instrumentation Tools

When You Bend Sheet Metal, The Neutral Axis Shifts Toward The Inside Surface Of The Bend.

Bronze, Hard Bronze, Cold Rolled Steel, Spring Steel, Etc.:

Related Post: