Kiln Firing Chart

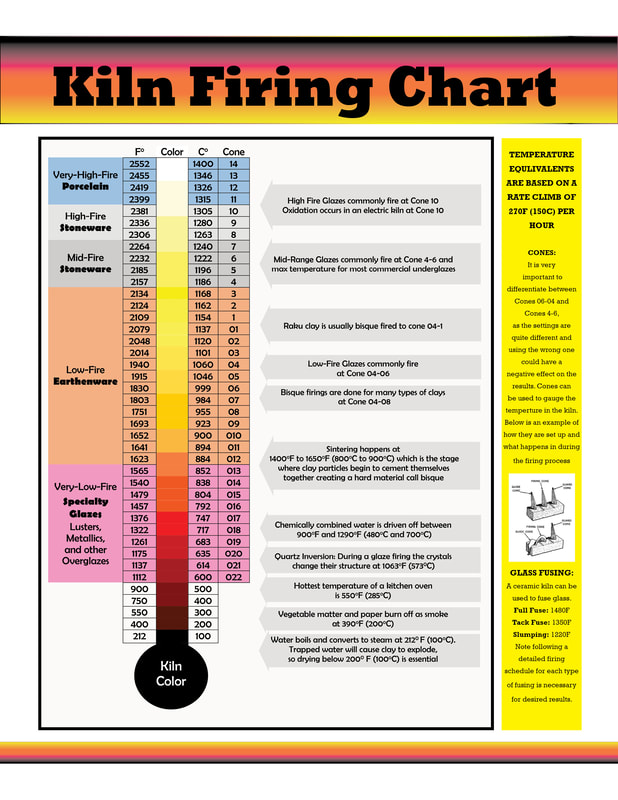

Kiln Firing Chart - Web firing ranges can be divided into three categories: Web use our kiln fire temperature chart to have a better understanding of what happens to clay in the kiln at each stage of the firing process. This is a table describing cone temperatures in celsius. Web not sure how to start firing your new electric kiln? We know the ins and outs of kiln firing. Web cone temperature chart in celsius. This guide from soul ceramics will walk you through all the steps so you'll be up and running fast! Your optimal parameters may vary based on coe, thickness, shape, and other factors. For manual electric kilns with a commercial downdraft vent. If you want to comb your glass, around 1634f / 890c is the right top temperature for your kiln firing schedule (see video below). This is a slow increase in temperature at the initial part of the firing when water is still present in the clay, the clay is vulnerable to being cracked by steam trying to escape from the clay at this stage, which is why it is important that your piece is bone. Web cone temperature chart in celsius. Web firing ranges. Firing_chart_fahrenheit_v1.2.pdf (823.3 kb) images of the schedules: Web what the kiln is doing. A firing program is either entered into a kiln controller or on kilns without controllers it is replicated by turning up and down temperature switches. Web use our kiln fire temperature chart to have a better understanding of what happens to clay in the kiln at each. Do not read this once and think you’ve got it! Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and wondered what they truly signify? Read through our overview of kiln firing, cones and cone temperature charts. Recently, a customer’s kiln slowed down to 102°f (56°c) at 2150°f (1176°c). Web download kiln. What is happening to the clay. Web glass glows red at this heat. Every kiln is different and every make of glass behaves differently in the kiln. Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and wondered what they truly signify? Download a pdf version of this chart for free. Email us if you have questions. Web what the kiln is doing. It can sometimes seem like the end of the process—but don't forget that all of the chemistry you've set up is about to actually take place for real! *many people forget to put the cone in the sitter as they load the kiln, but once they do, they. Web $ ceramic cone chart: The range at which thermal shock can occur. What is happening to the clay. If you want to comb your glass, around 1634f / 890c is the right top temperature for your kiln firing schedule (see video below). This is a table describing cone temperatures in celsius. Web $ ceramic cone chart: Consult your glass supplier to determine your best approach. This is a slow increase in temperature at the initial part of the firing when water is still present in the clay, the clay is vulnerable to being cracked by steam trying to escape from the clay at this stage, which is why it is important. This is a table describing cone temperatures in celsius. Firing_chart_fahrenheit_v1.2.pdf (823.3 kb) images of the schedules: For manual electric kilns with a commercial downdraft vent. *many people forget to put the cone in the sitter as they load the kiln, but once they do, they rarely forget ever again! Web download kiln firing charts: It can sometimes seem like the end of the process—but don't forget that all of the chemistry you've set up is about to actually take place for real! Firing converts ceramic work from weak greenware into a strong, durable form.as the temperature in a kiln rises,many changes take place in the clay;and understanding what happens during the firing can help. Firing converts ceramic work from weak greenware into a strong, durable form.as the temperature in a kiln rises,many changes take place in the clay;and understanding what happens during the firing can help you avoid problems.the following chart provides highlights of what happens when firing clay. Ceramic firing kiln prep, kiln schedules, ceramic firing programs for low fire, mid range and. Web each one of the lines in the chart represents a segment or hold time within a segment and the slope of the line represents the rate of firing. Email us if you have questions. Download a pdf version of this chart for free. Every kiln is different and every make of glass behaves differently in the kiln. This is a table describing cone temperatures in celsius. The following cones (022 to 011) are in a “very low” firing range. Web use our kiln fire temperature chart to have a better understanding of what happens to clay in the kiln at each stage of the firing process. Your optimal parameters may vary based on coe, thickness, shape, and other factors. This is a slow increase in temperature at the initial part of the firing when water is still present in the clay, the clay is vulnerable to being cracked by steam trying to escape from the clay at this stage, which is why it is important that your piece is bone. This schedule can be followed for kilns with a temperature gauge and timer: If you want to comb your glass, around 1634f / 890c is the right top temperature for your kiln firing schedule (see video below). Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and wondered what they truly signify? Web glass glows red at this heat. Firing converts ceramic work from weak greenware into a strong, durable permanent form. Web find cone temperature information. Firing_chart_fahrenheit_v1.2.pdf (823.3 kb) images of the schedules:

Firing temperatures Ceramic glaze recipes, Pottery techniques

Kiln Firing Log Sheet

![Kiln Firing Chart for Pottery and Ceramics [Infographic]](https://www.kilncontrol.com/wp-content/uploads/2023/08/Kiln-Firing-Chart-Blog-Header-1.png)

Kiln Firing Chart for Pottery and Ceramics [Infographic]

Kiln Firing Chart Poster Payhip

Kiln firing chart Ceramics, Pottery Ceramic glaze recipes

Ceramics Posters MY SITE

Joe Kowalczyk's Adventures in Kiln Repair Getting A New Kiln? Some

Pyrometric Cone Chart for Kiln Firing

Kiln Firing Chart Pottery

Kiln Firing Schedules Kiln firing, Kiln, Schedule

Firing Converts Ceramic Work From Weak Greenware Into A Strong, Durable Form.as The Temperature In A Kiln Rises,Many Changes Take Place In The Clay;And Understanding What Happens During The Firing Can Help You Avoid Problems.the Following Chart Provides Highlights Of What Happens When Firing Clay.

We Know The Ins And Outs Of Kiln Firing.

Do Not Read This Once And Think You’ve Got It!

A Firing Program Is Either Entered Into A Kiln Controller Or On Kilns Without Controllers It Is Replicated By Turning Up And Down Temperature Switches.

Related Post: