Machine Finish Chart

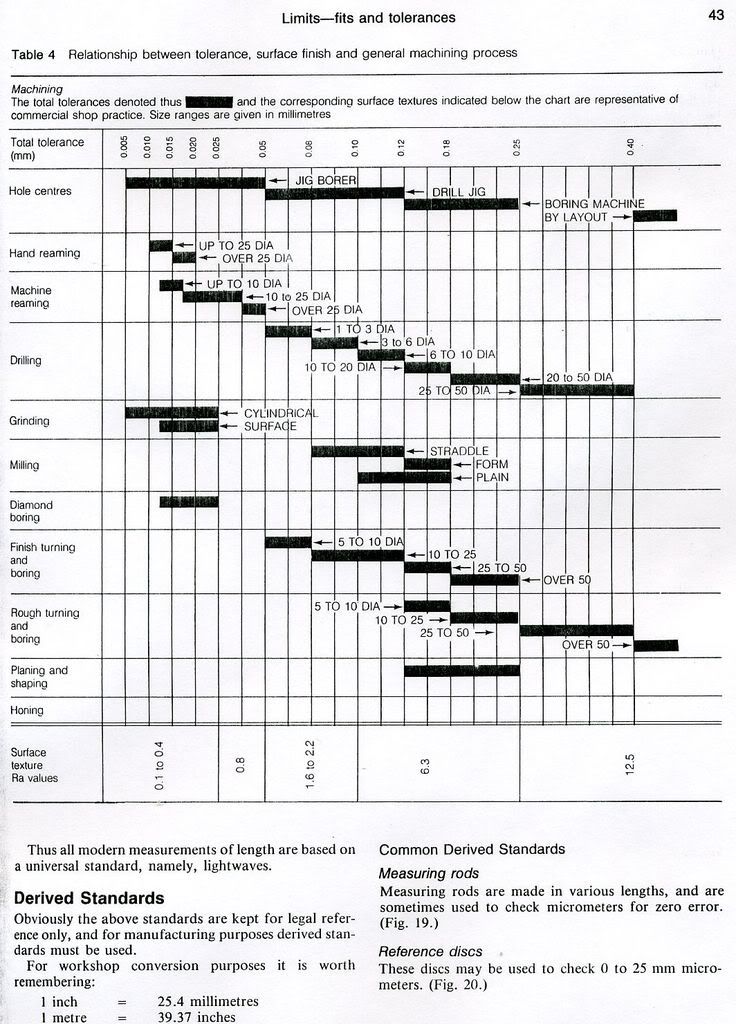

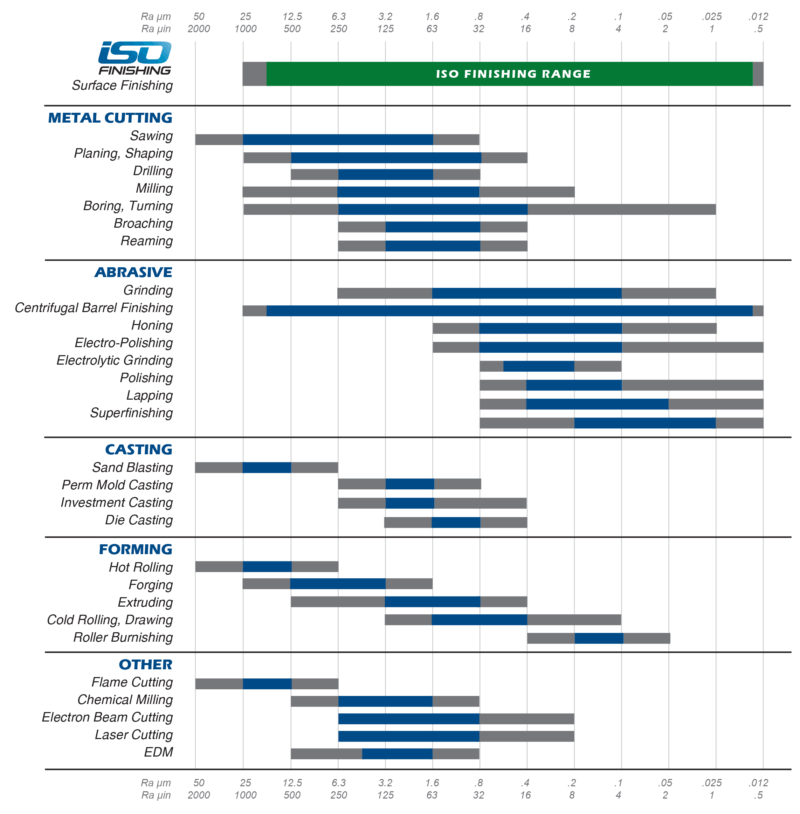

Machine Finish Chart - Minorly visible tool marks with a standard surface roughness (ra) of 3.2μm. One of the surface texture parameters is surface roughness. Web the surface finishing has 6 impacts for a machined parts: When discussing cnc machining, one of the most important variables is what finish will be applied to the product. Why does surface finish matter in engineering processes? Web here’s a table with a chart demonstrating the relative surface roughness of several production processes: Web machining surface finish chart, conversion, comparator, method, degree, ra, rz, rms. Methods for measuring surface roughness. There are a variety of surface finishes charts that can. Surface roughness average ra vs manufacturing process. Get a specific texture or appearance to have outstanding looks for a product. Improve mating properties, wear resistance, fatigue strength, contact stiffness, vibration and noise of mechanical parts. Why does surface finish matter in engineering processes? Improve corrosion and chemical resistance effectively. N = new iso (grade) scale numbers. Introducing the machining surface finish chart, conversion, comparator photos, method, finish degree, ra, rz, rms for iron and steel castings by dandong foundry in china. Rt = roughness, total in microns. Surface finishes define the final appearance of parts after machining. A guide to understanding surface finishing. Manufacturers always use it as a reference material to ensure quality in the. Get a specific texture or appearance to have outstanding looks for a product. January 2, 2017 anand 10 comments surface finish. Web the surface finishing has 6 impacts for a machined parts: Web surface finish specification and comparison. Have you come across a surface finishing chart? It is typically defined in terms of its roughness, waviness, and lay. Find equivalent materials standards for sae, aisi, din, wnr, uni, uns, bs, anfor, and js. Minorly visible tool marks with a standard surface roughness (ra) of 3.2μm. Web surface finish specification and comparison. Surface finishes may be increased to 1.6, 0.8, to 0.4μm. This diagram shows how waviness, lay, and roughness are related to each other: Methods for measuring surface roughness. Calculate the turning surface finish based on corner radius and feedrate. There are a variety of surface finishes charts that can. Check how injection moulding surface finish can be defined and used as a functional or aesthetical feature. Web the only surface finishing chart (and guide) you’ll ever need. A chart can look complex and confusing, but it shows important data. One of the surface texture parameters is surface roughness. Surface finish is a term describing the texture of the surface of a printed object. Web how to measure surface roughness. Methods for measuring surface roughness. A guide to understanding surface finishing. Cover or eliminate surface defects. Web surface roughness chart. Web the term “surface finish” usually refers to the level of polishing or texturing applied to the surface of a part or component. Web the finish on a metal surface after machining depends mainly on the material and some are as follows. Manufacturers always use it as a reference material to ensure quality in the manufacturing process. Web surface finish charts are used to depict the average roughness profile of a certain material after different processing techniques i.e., grinding, polishing and buffing. This. Carbide grades from all the major cutting tool companies in the industry. So, what are surface finishes in detail? One of the surface texture parameters is surface roughness. A comprehensive understanding of these factors enables machinists to optimize surface finish and minimize defects. Rt = roughness, total in microns. Web the finish on a metal surface after machining depends mainly on the material and some are as follows. This diagram shows how waviness, lay, and roughness are related to each other: It depends on the structure of the metal before and after machining, depends on cutting conditions such as type and degree of sharpness of the cutting tool, depth. Web surface finishes chart for cnc machining: Web surface roughness chart. Ra [micorns] ra [micro inches] n (iso) Detailed machining data for 700 raw materials. Cover or eliminate surface defects. A guide to understanding surface finishing. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or thinner film, and a rougher or finer surface finish. Web the surface finishing has 6 impacts for a machined parts: Minorly visible tool marks with a standard surface roughness (ra) of 3.2μm. Engineering prints call out a great many things in their attempt to make sure the part that gets made matches the designer’s intent. Calculate the turning surface finish based on corner radius and feedrate. Surface finishes define the final appearance of parts after machining. Do you work with surfaces often? However, it is not uncommon in machine shops for the term surface finish to be used to describe only surface roughness. By looking at these charts we can choose material and process wisely for getting the. The degree of roughness on the product surface affects its durability and performance during usage.

Lecture Notes Engineering Drawing Part 4

How Much Will Electropolishing Improve the Surface Finish of My Part

Machining_finishes3.jpg Photo by oldtiffie Photobucket

Surface Roughness Chart Comparison ISO Finishing

Machine Finishes Chart Open Discussion Sturgeon's House

303 Stainless Bore Feeds and speeds Page 2

Surface Finish Symbols and Roughness Conversion Chart Tables

The Basics of Surface Finish GD&T Basics

machining surface finish guide Delinda Bassett

Surface Finish Machinng Chart.pdf Surface Roughness Machining

Why Does Surface Finish Matter In Engineering Processes?

Processes Involving The Use Of Machines Impose Characteristic Irregularities On Their Products’ Surfaces.

Machining N9 250 6.3 N10 500 12.5 Rough Machining N11 1000 25 N12 2000.

Web The Term “Surface Finish” Usually Refers To The Level Of Polishing Or Texturing Applied To The Surface Of A Part Or Component.

Related Post: