Metal Finishes Chart

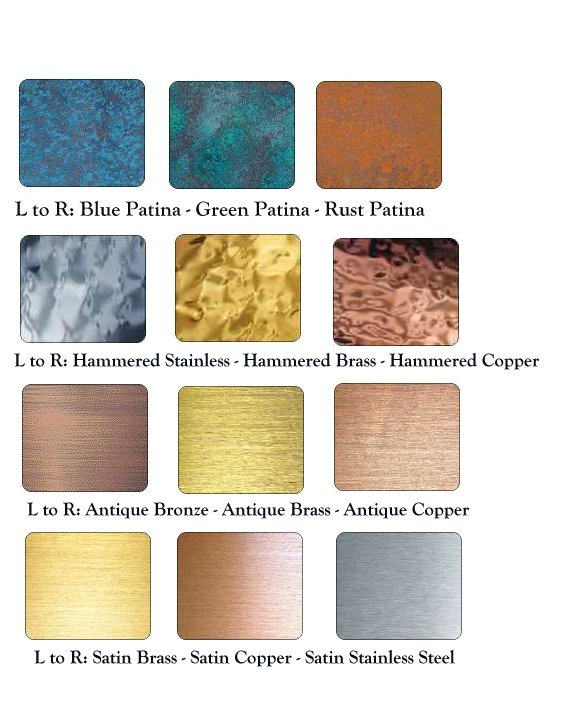

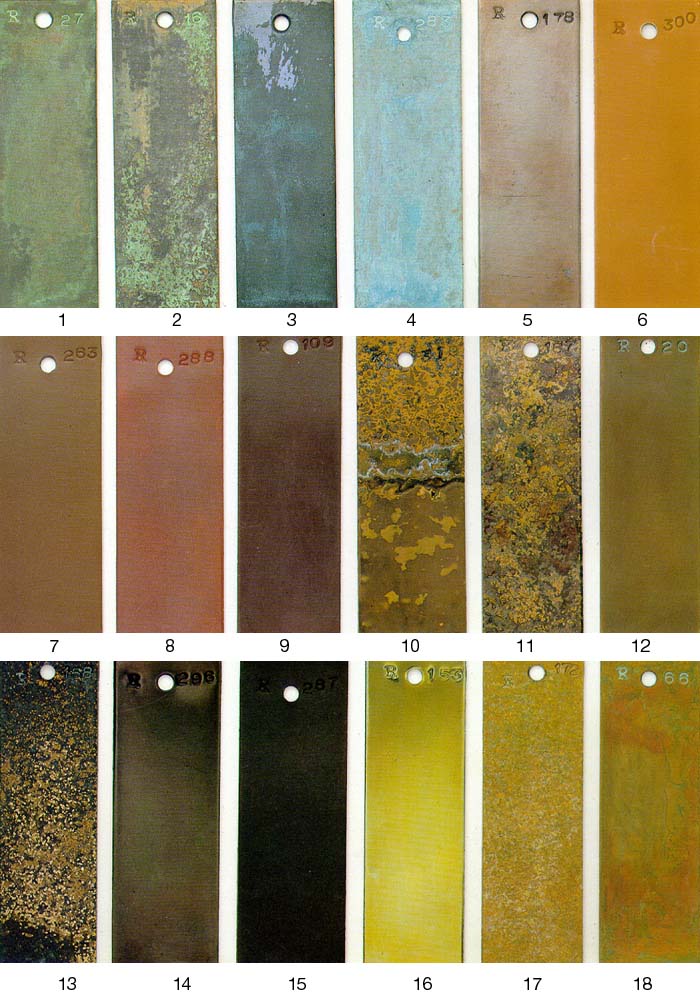

Metal Finishes Chart - The first four chapters cover finishes for the specific architectural metals, aluminum, the copper alloys, stainless steel, and carbon steel and iron respectively. Web result surface finish roughness chart. Antique finishes are made to look slightly rougher, rather than smooth as if they have developed a patina over time. This look works beautifully in rustic designs. Satin (brushed) titanium (pvd) coated stainless steel. Our chart of surface finishes by manufacturing process (see above) gives both. Web result in short, numerous types of metal finishing processes are used for a variety of purposes. The first column indicates the bhma finish code, the second column represents the us standard finish code (when available) and the third column indicates the finish and base metal that the finish is applied to. You can compare surface finishes by looking at a surface finish roughness chart. Surface finishing is a critical step in the production of metal components. This guide reviews some major finishing methods, as well as applications and considerations for choosing a metal finishing process. 3 surface finish considerations for sheet metal fabricated parts. Web result finish code numbers nearest/ base former u.s. Manufacturers leverage metal finishing solutions to improve corrosion resistance, surface hardness, and other mechanical property enhancements to their metal components. Web result iml. 3 surface finish considerations for sheet metal fabricated parts. Surface finishing is a critical step in the production of metal components. Web result surface finish roughness chart. Different types of metal finishes. 1 surface finish scales for sheet metal fabricated parts. 1 surface finish scales for sheet metal fabricated parts. For your reference, this metal finish cross reference chart provides typical finishes and plating descriptions for aluminum and stainless steel surfaces. Web result the main finish types are antiqued, polished, brushed, hammered, and satin. Three (3) major characteristics can define the surface finish. Web result base metal finish code; Three (3) major characteristics can define the surface finish. Surface finishing is a critical step in the production of metal components. Our chart of surface finishes by manufacturing process (see above) gives both. Web result finishes chart finishes chart nbha bhma materials finishes 3 605 bright brass, clear lacquered 4 606 satin brass, clear lacquered 5 609 satin brass, oxidized. 14a 626 kwi 11p 643e 716. A quality metal surface treatment will improve any completed component, making the part look better, and crucially, last longer. You can compare surface finishes by looking at a surface finish roughness chart. Our chart of surface finishes by manufacturing process (see above) gives both. It’s likely that the actual finishes will vary to some. Antique finishes are made to look slightly rougher, rather than smooth as if they have developed a patina over time. Our chart of surface finishes by manufacturing process (see above) gives both. Manufacturers leverage metal finishing solutions to improve corrosion resistance, surface hardness, and other mechanical property enhancements to their metal components. The most commonly used parameter is. Surface finishing. Finishes misc 689 aluminum 690 dark statuary bronze 691 light bronze (dull bronze) 692 tan 693 black 695 medium amber 696 brass (gold) 1b black Code description material equivalent 650 dark oxidized statuary bronze steel us20a plated, clear coated 651 bright chromium plated steel us26 652 satin chromium plated steel us26d 653 bright stainless steel stainless steel 400 series Satin. The first four chapters cover finishes for the specific architectural metals, aluminum, the copper alloys, stainless steel, and carbon steel and iron respectively. Our chart of surface finishes by manufacturing process (see above) gives both. There are various parameters for measuring surface roughness, but the most common is the ra. Web result finishes chart finishes chart nbha bhma materials finishes. Web result specifications are similar but not always identical. 4 recommended default sheet metal tolerances. Web result surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. Web result finishes chart finishes chart nbha bhma materials finishes 3 605 bright brass, clear lacquered 4 606 satin brass, clear lacquered. The most commonly used parameter is. *usually a residen al finish. Web result finishes chart finishes chart nbha bhma materials finishes 3 605 bright brass, clear lacquered 4 606 satin brass, clear lacquered 5 609 satin brass, oxidized and relieved (antiqued) 9 611 bright bronze, clear lacquered 10 612 satin bronze, clear lacquered 10b 613 satin bronze, oxidized and oil. A quality metal surface treatment will improve any completed component, making the part look better, and crucially, last longer. 2 creating beautiful surface finishes for sheet metal fabricated parts. Web result finishes chart finishes chart nbha bhma materials finishes 3 605 bright brass, clear lacquered 4 606 satin brass, clear lacquered 5 609 satin brass, oxidized and relieved (antiqued) 9 611 bright bronze, clear lacquered 10 612 satin bronze, clear lacquered 10b 613 satin bronze, oxidized and oil rubbed Our chart of surface finishes by manufacturing process (see above) gives both. Here we’ll walk you through different types of metal finishes, and the popular, cheap, and durable options. You can compare surface finishes by looking at a surface finish roughness chart. The most commonly used parameter is. There are various parameters for measuring surface roughness, but the most common is the ra. Web result surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. When we try to measure a surface finish, the methods fall into three categories: Web result finish chart ansi/mhms code us code finish description base material common names 600 usp primed for painting steel 601 us1b bright black japanned steel. Always check the actual specification and you can always call our engineers for guidance. Web result base metal finish code; The ra indicate the arithmetical mean deviation on the surface. *usually a residen al finish. Brass satin (brushed) copper polished.

Metal Finishes Gallery Metal Works Gallery Metalworks

Stainless Steel Sheet and Plate Finishes Euro Steel, SA

Alumet Anodized Finishes Color Chart by Alice Buchman Creative Design

Steel Finish Chart A Visual Reference of Charts Chart Master

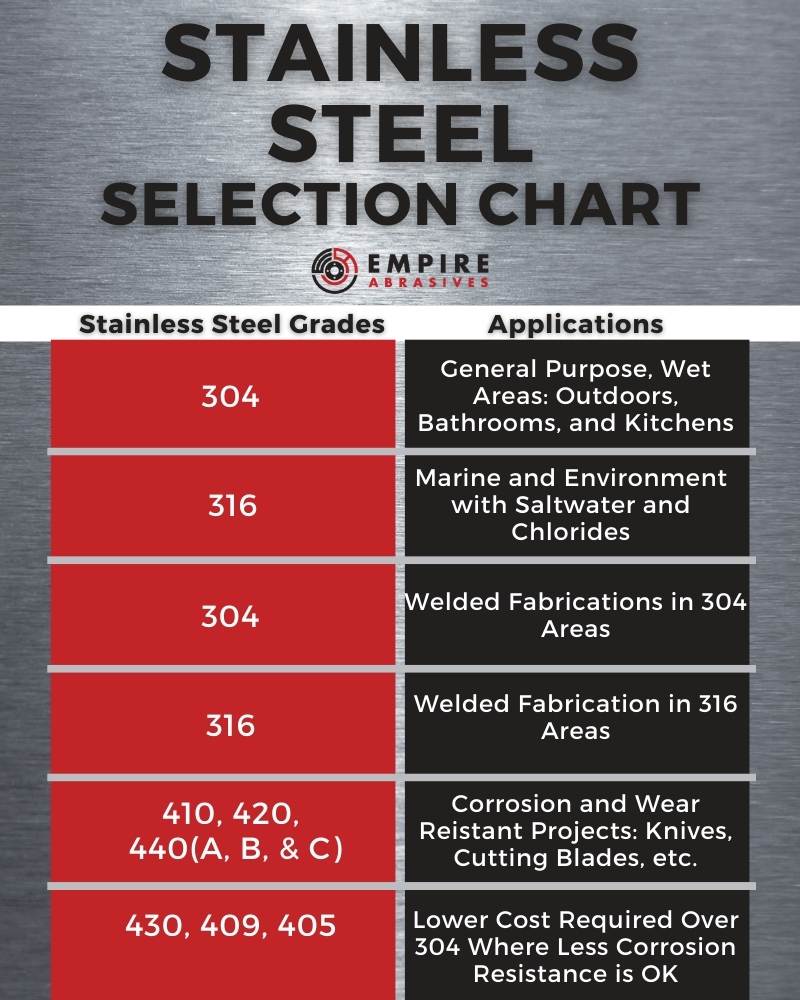

Ultimate Guide Stainless Steel Fabrication, Grinding, and Finishing

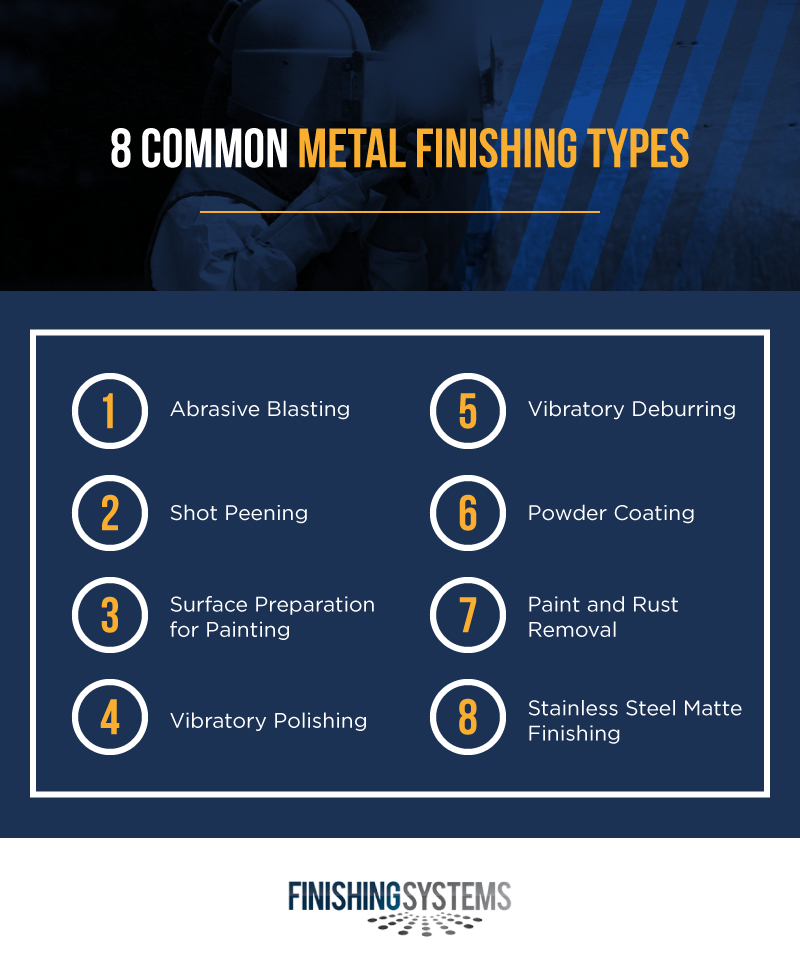

Metal Finishing Types What to Choose Finishing Systems

METALS FINISH GUIDE(AB)

Standard Metal Finishes Chart

METALS FINISH GUIDE(AB)

Metal Finishes Metal Finishing, Plating, Polishing, Restoration NJ

Web Result Finish Code Numbers Nearest/ Base Former U.s.

Web Result Metal Finishing Chart Is A Visual Representation Or Graphical Tool That Provides Information About Different Surface Finishes Or Textures That Can Be Applied To Metal Or Other Materials.

Web Result This Metal Finish Chart Is Provided As A Guideline Only.

It Is A Measure Of The Complete Texture Of A Product’s Surface That Is Defined By Three Characteristics Of Surface Roughness, Waviness, And Lay.

Related Post: