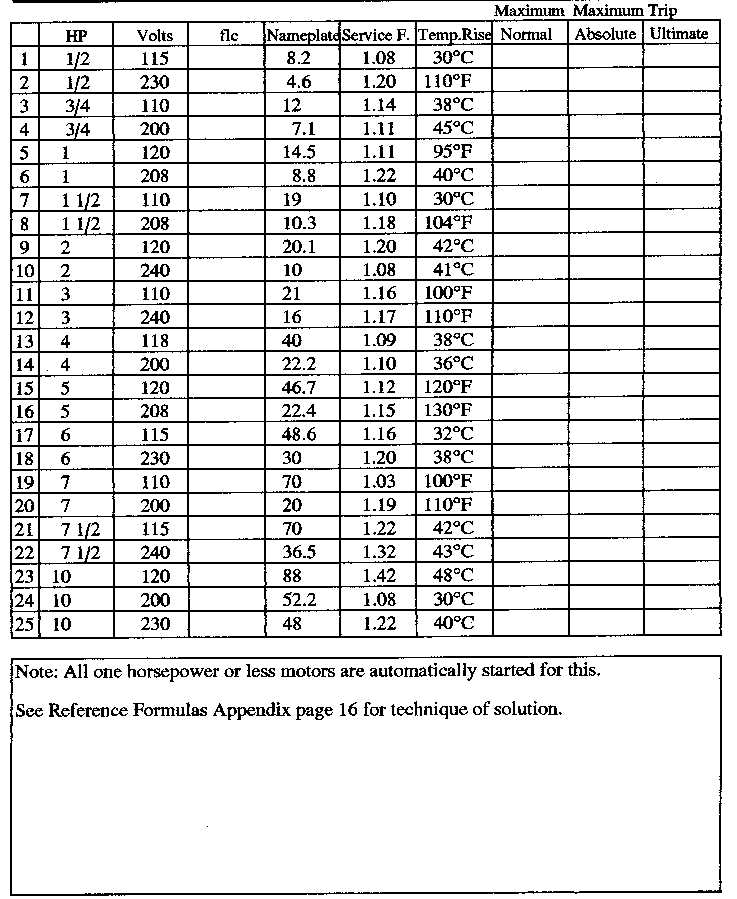

Motor Overload Sizing Chart

Motor Overload Sizing Chart - November 17, 2022 by simon mugo. Maximum size of time delay fuse = 300%x6 = 19 amp. If motor amps are not known, an Calculations for maximum motor overload protection, under normal conditions: Web the type a thermal overload relay (olr) is a bimetallic device which, with the properly selected wire and heaters, will provide motor protection for running and stalled rotor overloads in motor circuits not exceeding 600 volts. The motor overload, explains how to properly size overload protection for a typical motor installation using separate overload protection, and part iv will discuss how to properly size motor branch. Web selection of heater elements for overload relays. Maximum overload setting for motors with a marked service factor of 1.15 or greater = np amperes x 125% 35 ampere x 125% = 43.7 ampere @ 44 ampere. Specific applications may require class 10 or class 30. Web the table below should be used to determine which column of motor full load amperes applies for heater selection. Web class 9065 catalog for overload relays and thermal unit selection. An example calculation to size a motor overload protection device is: Web this will provide integral horsepower motors with protection between 105 and 115%. If motor amps are not. Web the table below should be used to determine which column of motor full load amperes applies for heater selection. Web valuable electrical tables & charts. Sizing depends on ambient temperatures and motor service factor. Typical single phase & three phase motor data: For more manufacturer of the motor. For applications requiring class 30 protection, type wl heater. Web each manufacturer has their own rules. Calculations for maximum motor overload protection, under normal conditions: November 17, 2022 by simon mugo. 40 ec and service factor : Sizing depends on ambient temperatures and motor service factor. Web standard fuses and circuit breaker sizes can be found in nec 240.6 (a). Web selection of heater elements for overload relays. 40 ec and service factor : The value of 30.9 a falls between 30.0 a (w64) and 32.5 a (w66 Motors with 1.15 to 1.25 service factor use 100% of flc. 40 ec and service factor : Web this will provide integral horsepower motors with protection between 105 and 115%. The motor overload, explains how to properly size overload protection for a typical motor installation using separate overload protection, and part iv will discuss how to properly size motor branch.. This fuse sizing is normally large enough to allow the overload protective device to operate on overloads without opening the fuse. Motor amps higher or lower than the values listed will vary depending on the type and below for a particular motor. Yet for many cases, this fuse amp rating selection is smaller than the maximums Search amazon for your. An example calculation to size a motor overload protection device is: Heater table number is found in the column under the type of overload and phase. Actual motor amps may be current is not known. Motor amps higher or lower than the values listed will vary depending on the type and below for a particular motor. Web with properly sized. Motors with 1.15 to 1.25 service factor use 100% of flc. An example calculation to size a motor overload protection device is: Calculations for maximum motor overload protection, under normal conditions: Typical single phase & three phase motor data: Web controller size motor amp phase 1. Ua = actual voltage 254 ∆/440 y v (actual voltage) umin = 220 ∆/380 y v (minimum values in the voltage range) umax = 277 ∆/480 y v (maximum values in the voltage range) Web this will provide integral horsepower motors with protection between 105 and 115%. For applications requiring class 30 protection, type wl heater. Web the type a. Maximum overload setting for motors with a marked service factor of 1.15 or greater = np amperes x 125% Web approximate thermal unit selection based on horsepower and voltage. Web this will provide integral horsepower motors with protection between 105 and 115%. Web the table below should be used to determine which column of motor full load amperes applies for. Use only when motor full load caution: Np amps, amperes from the motor name plate. Sizing depends on ambient temperatures and motor service factor. 35 ampere x 125% = 43.7 ampere @ 44 ampere. Selecting and sizing dol parts. 40 ec and service factor : Maximum size of time delay fuse = 300%x6 = 19 amp. For more manufacturer of the motor. Maximum overload setting for motors with a marked service factor of 1.15 or greater = np amperes x 125% For applications requiring class 30 protection, type wl heater. The motor overload, explains how to properly size overload protection for a typical motor installation using separate overload protection, and part iv will discuss how to properly size motor branch. November 17, 2022 by simon mugo. Provides typical fla, sc protection, conductor size, and motor starter information. The tables are based on motors of approximately 1450rpm of average efficiency and power factor. Motors with 1.15 to 1.25 service factor use 100% of flc. The value of 30.9 a falls between 30.0 a (w64) and 32.5 a (w66

Overload Heater Chart Square D

Motor Overload Protection Chart Hot Sex Picture

Overload Heater Sizing Chart

How To Size Motor Overload Heaters

Motor Full Load Currents Guide Sizing a Current Transformer

![]()

Motor Thermal Overload Sizing Chart

Square D Thermal Overload Chart Online Shopping

Square D Motor Starter Heater Sizing Chart My XXX Hot Girl

Motor Starter Heater Sizing Chart

18 Credit Card Math Worksheets /

Refer To The Specified Table And Use The Controller Size And Motor Amps To Select The Heater Catalog Number.

Web Controller Size Motor Amp Phase 1.

The Size 1 And 2 Olr’s Have A Maximum Current Rating Of 26.2 And 45.0 Amperes Respectively.

Either Type N Or W Heater Elements Provide Class 20 Operation And Are Recommended For General Application.

Related Post: