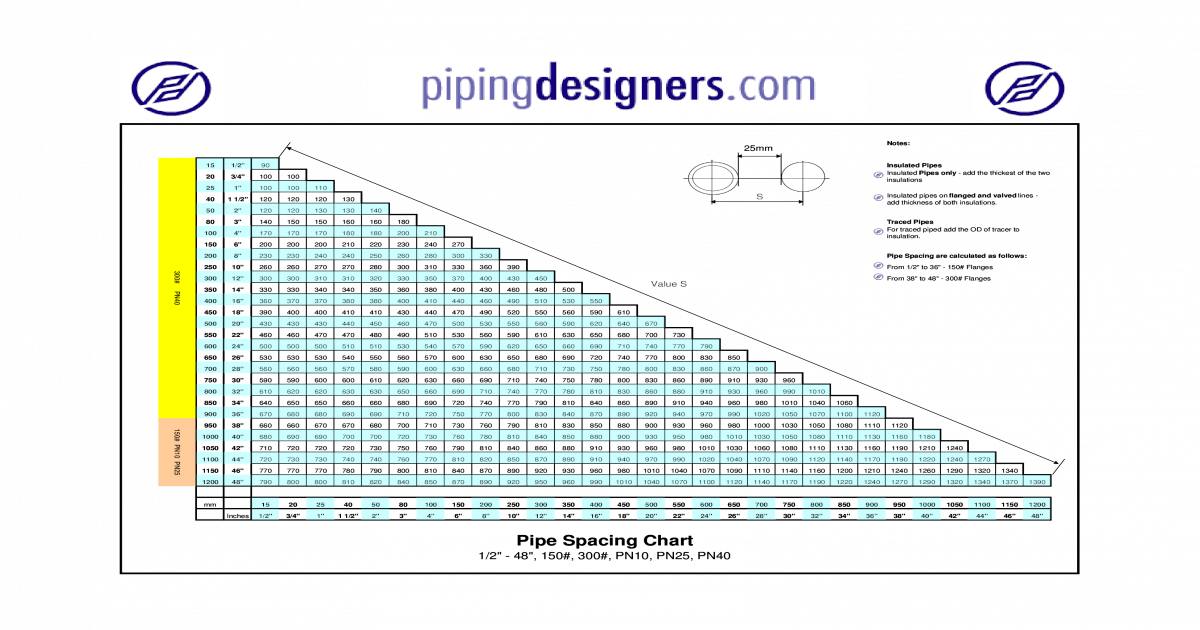

Pipe Spacing Chart

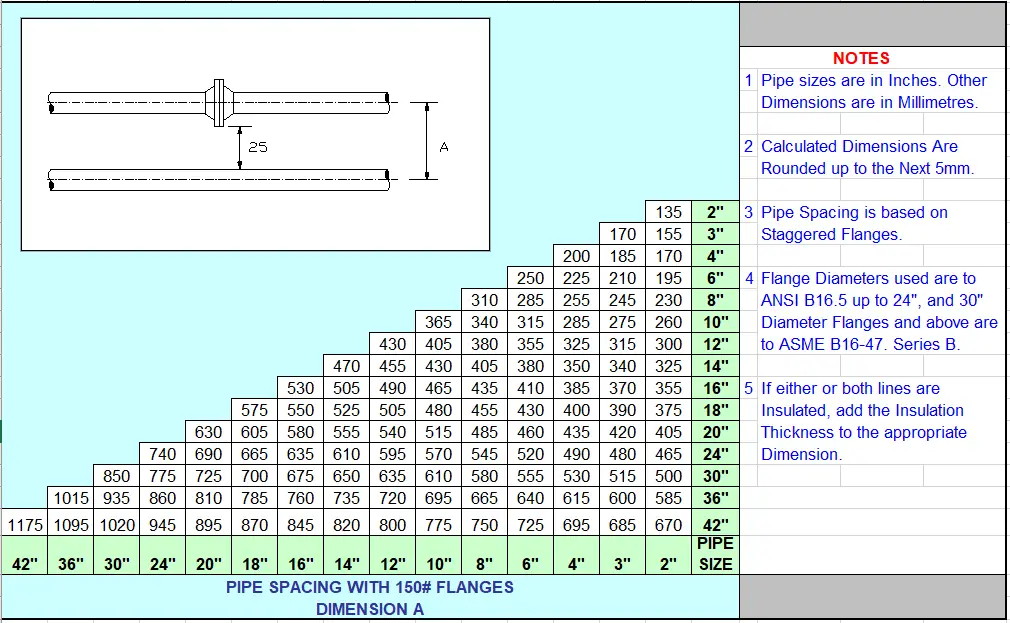

Pipe Spacing Chart - All dimensions are in millimeters unless otherwise stated. Spans or support spacing are based on maximum pipe deflections of 6.35 mm up to 6 and 12.7 mm for pipe sizes 8 and above. Pipe 2 flange od (inches): Spans are also provided for pipe deflection of 25 mm for all pipe sizes. Nominal pipe size and schedule; Web pipe spacing chart for flanged pipes of various sizes and pressure ratings | pdf | plumbing | building. C:documents and settingsmlayportmy documentsjunklibrpipe spacing chart.dwg model (1) author: Click to print our line sheet. Web pipe support span chart. Standardization of wrought steel pipe schedule and pipe. The quick and easy installation, use, and removal of the plugs have made testing plain end pipe simple. In such case, for economic reasons, clamped pipe supports at an angle of 45 degrees should be used. The span is the distance between two points where a pipe is supported, such as at two adjacent pipe hangers. Web use our ansi. Clear gap can be changed as per your company. Web pipe rack line spacing. A pipe support span chart is a table or diagram that provides information on the maximum allowable span for different types of piping and support configurations. Web pipe spacing calculator is a convenient tool to calculate the minimum spacing between pipes. Data given in based on. Web use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. The span is the distance between two points where a pipe is supported, such as at two adjacent pipe hangers. Web pipe support spacing table (chart) for carbon steel pipes. To determine the line spacing for insulated lines add the insulation thickness. C:documents and settingsmlayportmy documentsjunklibrpipe spacing chart.dwg model (1) author: Click to print our line sheet. Web use our ansi pipe schedule chart to determine the nominal pipe size, wall thickness, weight and schedule designations of carbon and stainless steel pipes. Web pipe support span chart. The quick and easy installation, use, and removal of the plugs have made testing plain. Dimensions 'a' and 'b' shown above are for uninsulated lines. Spacing between pipes on a pipe rack.larger spacing may be required if pipes have clamped supports. The quick and easy installation, use, and removal of the plugs have made testing plain end pipe simple. Web online piping spacing calculator. To determine the line spacing for insulated lines add the insulation. Spans are also provided for pipe deflection of 25 mm for all pipe sizes. Pipe 2 flange od (inches): Pipe schedule number is the standard method to define the thickness of the pipes used in process plants. Flange od from 26″ as per asme b16.47 type a. Select the applicable piping configuration from the four options provided to calculate the. Web online piping spacing calculator. Additional guides should be located in accordance with the pipe guide spacing chart shown below for standard weight carbon steel pipe or calculated from the following formula: Web pipe spacing chart for flanged pipes of various sizes and pressure ratings | pdf | plumbing | building. The span is the distance between two points where. Whenever two pipes run parallel to each other, piping designers or engineers must maintain a minimum gap between the two pipes or pipelines. The span is the distance between two points where a pipe is supported, such as at two adjacent pipe hangers. Web use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule. Flange od from 26″ as per asme b16.47 type a. Spacing can be calculated based on pipe od and flange od, between two flange ods or between two bare pipes. C:documents and settingsmlayportmy documentsjunklibrpipe spacing chart.dwg model (1) author: Select the applicable piping configuration from the four options provided to calculate the pipe center to center spacing. Additional guides should. Spacing between pipes on a pipe rack.larger spacing may be required if pipes have clamped supports. These formulas may involve factors such as the modulus of elasticity, moment of inertia, and other mechanical properties of the pipe material. Web the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Nominal. For traced piped add the od of tracer to insulation. Web use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. In such case, for economic reasons, clamped pipe supports at an angle of 45 degrees should be used. Click to print our line sheet. Web the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Web online piping spacing calculator. Pipe outside diameters as per ansi asme b36.10. Additional guides should be located in accordance with the pipe guide spacing chart shown below for standard weight carbon steel pipe or calculated from the following formula: Web this spacing chart is a kind of general guideline that gives an idea about spacing requirements. Dimensions of pipes and tubes, materials and capacities, pressure drop calculations and charts, insulation and heat loss diagrams. Pipe 2 flange od (inches): A pipe support span chart is a table or diagram that provides information on the maximum allowable span for different types of piping and support configurations. Standardization of wrought steel pipe schedule and pipe. Spacing between pipes on a pipe rack.larger spacing may be required if pipes have clamped supports. Gripsafe plugs have been valuable assets on the lngc site. To determine the line spacing for insulated lines add the insulation thickness to dimensions 'a' and 'b'.Pipe Spacing Chart PDF PDF

Minimum Pipe Spacing Chart Pipe (Fluid Conveyance) Hydraulic

Pipe Spacing Chart Piping Designers . Spacing 15mm · Pipe Spacing

00 PI STD 0004_D4 Pipe Spacing Chart

PIPE SPACING CHART.xls

Pipe Spacing Calculator

Pipe Spacing Chart Pipeline Spacing Chart (PDF) What is Piping

Pipe Spacing Chart.xls Dimension Pipe (Fluid Conveyance)

Pin on HVAC

Pipe Line Spacing Chart

Web Pipe Rack Line Spacing.

Centre To Centre Between The Pipes = Half O/D (Outside Diameter) Of The Bigger Size Pipe Flange + Insulation Thickness Of Bigger Size Pipe (If Applicable) + 25Mm + Half O/D (Outside Diameter) Of The Smaller Size Pipe + Insulation Thickness Of Smaller Size Pipe (If Applicable).

Calculate Spacing Between Pipes On A Pipe Rack Based On Dimensional Standard Asme B16.5 And B16.47.

Nominal Pipe Size And Schedule;

Related Post: