Plasma Cutting Chart

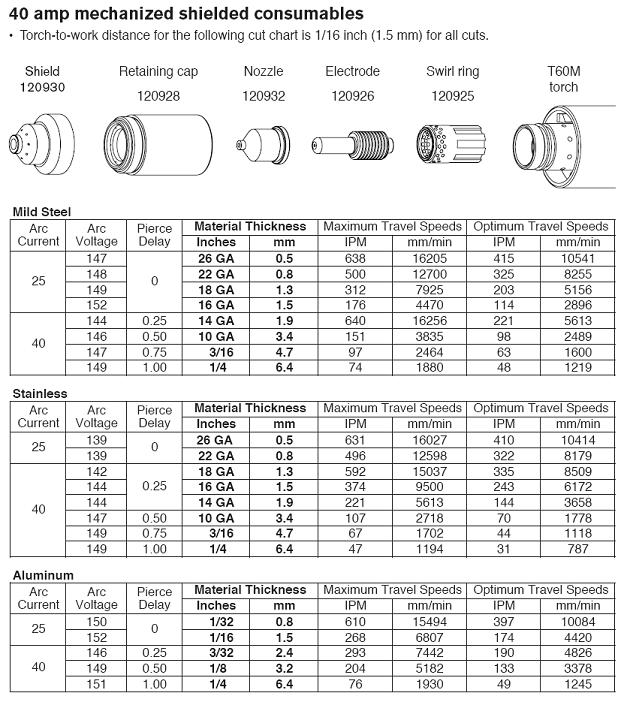

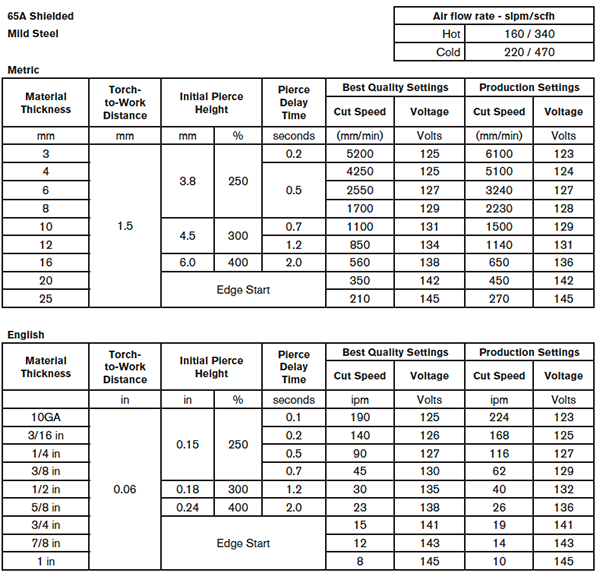

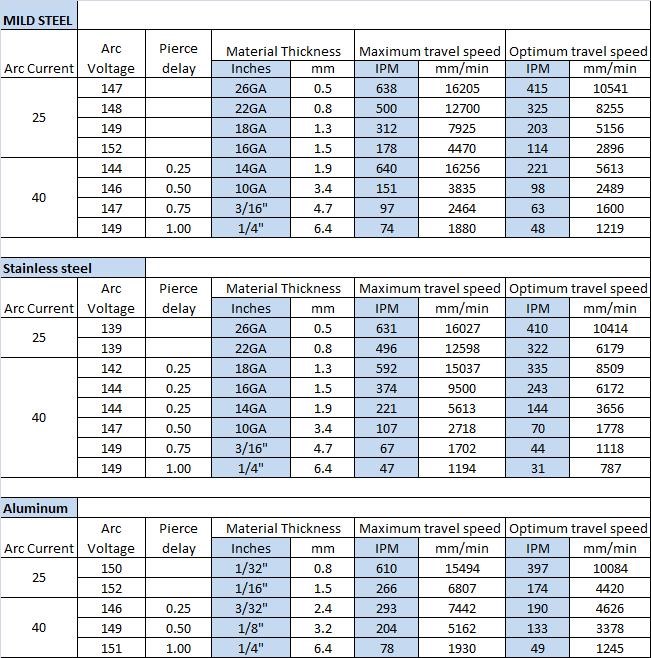

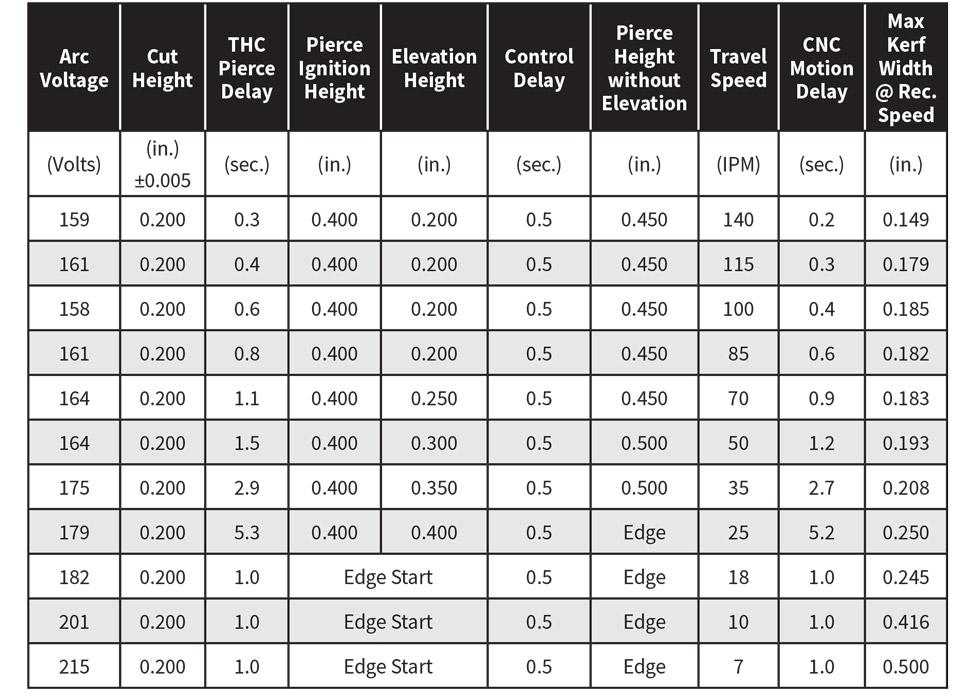

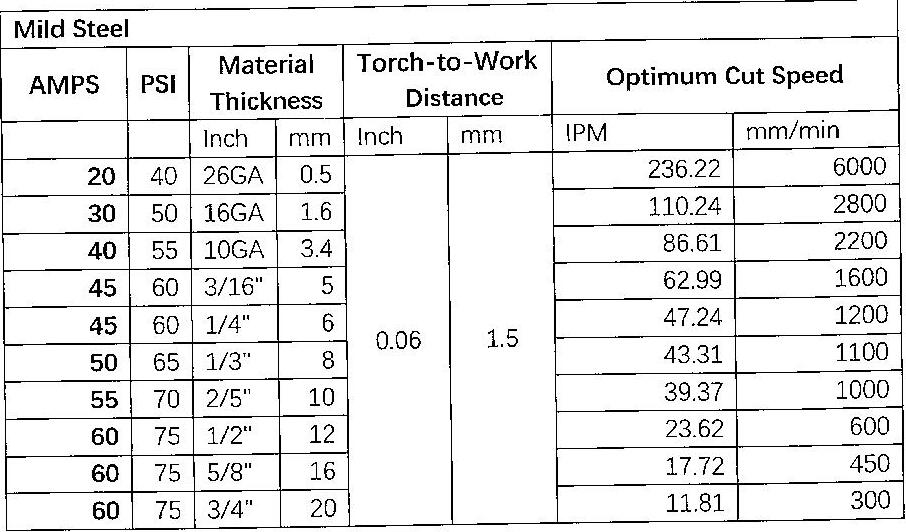

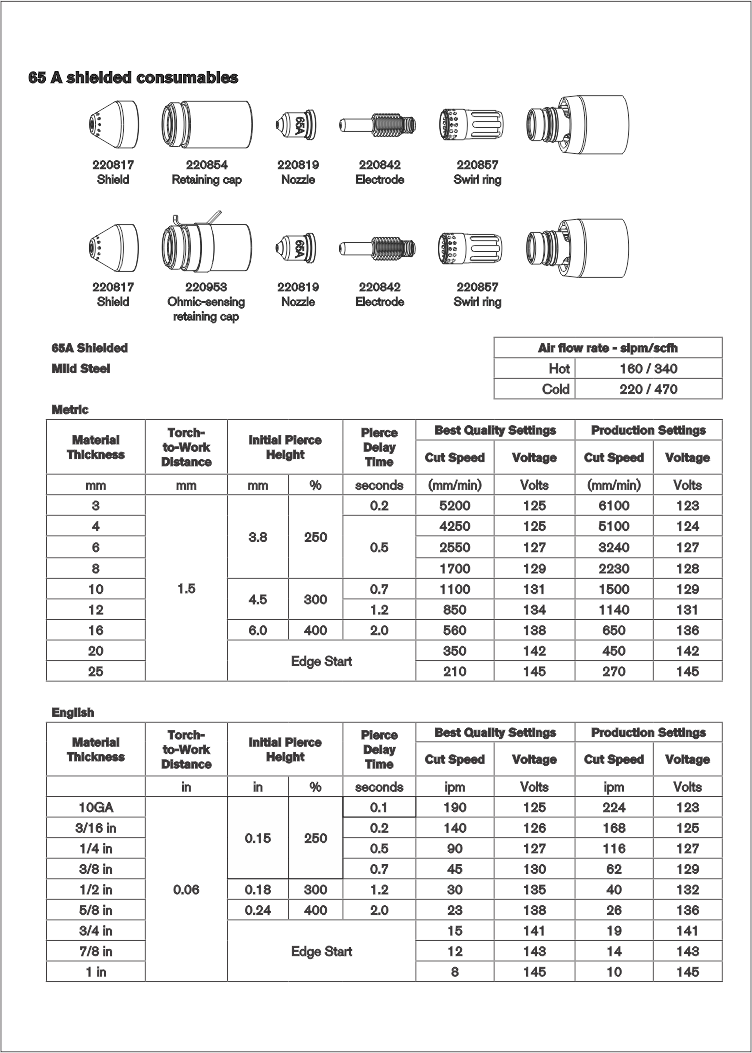

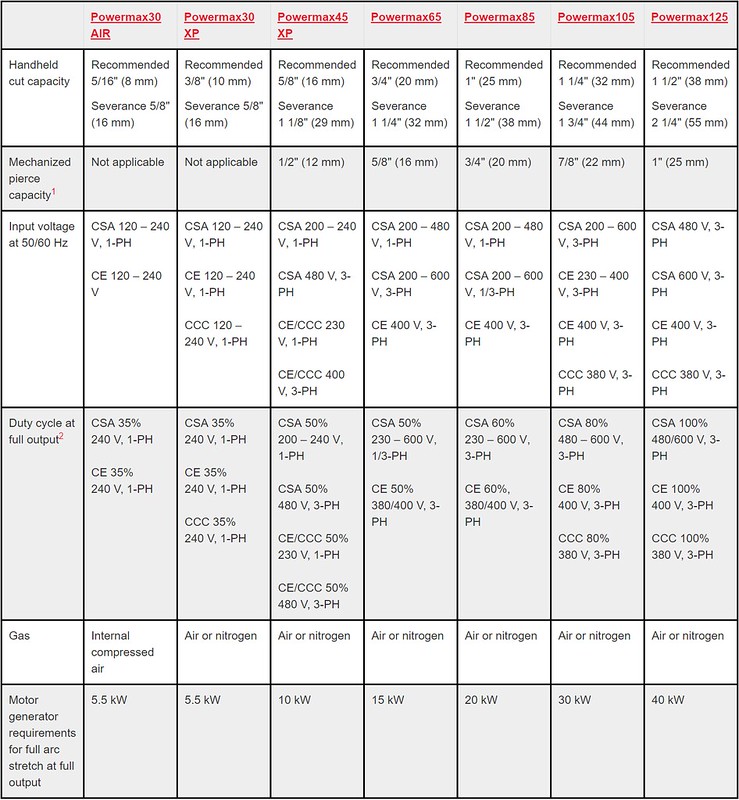

Plasma Cutting Chart - Always start with the settings found in those charts. Oxyfuel has relatively slow cutting speeds. Web charts as needed to achieve optimal results for your cutting equipment and environment. Web all of our manuals contain very detailed cut charts, including plasma cut charts for aluminum. Cutting mild steel, stainless steel, and aluminum at 45 a with air using shielded. Select the appropriate plasma cutting setting process for: For more detailed information, refer to the gas console control and. Web by ethan maxwell / january 30, 2023. Refer to the plasma cutter's user manual: The good news is that an air compressor attaches to the back of a plasma cutter in the same way a gas tank connects to the back of a welder. A consumable diagram with part numbers precedes each cut chart. I just got my everlast 82i cnc package plasma yesterday. Web all of our manuals contain very detailed cut charts, including plasma cut charts for stainless steel. You can always make slight adjustments later if needed. I was wondering if anyone has a cut chart to get me in the. Comparing cutting speed and productivity, the plasma cutting system is much faster than a single oxyfuel torch up to 2.5 to 2.75 in. By matching the correct air pressure settings with the correct amperage settings for. Oxyfuel has relatively slow cutting speeds. You can always make slight adjustments later if needed. It is critical that these plasma cutter settings are. The cut charts are divided into two areas: Unlike welding machines, every australian market plasma cutter you can buy is made to work on compressed air only, including unimig machines. Web all of our manuals contain very detailed cut charts, including plasma cut charts for stainless steel. Always start with the settings found in those charts and then make slight. Orifice hole size 1mm =.03937. Web with more intricate parts in thinner steel (and with stainless steel and aluminum), the plasma cutting system would be the best choice. Explain which consumable set to use and at what amperage; Down2earths10 september 18, 2020, 8:34pm 1. This chart provides a guideline for different material thicknesses, gas types, and desired cut qualities. Amperage, measured in amps, determines the intensity of the plasma arc. The following sections provide cut charts for each set of mechanized consumables. By matching the correct air pressure settings with the correct amperage settings for. Cutting mild steel, stainless steel, and aluminum at 45 a with air using shielded. Web be sure to follow the plasma cutter settings and. Web with more intricate parts in thinner steel (and with stainless steel and aluminum), the plasma cutting system would be the best choice. Web by ethan maxwell / january 30, 2023. Cut charts are included for: Depending on the handheld torch model, move the torch lock switch found on your plasma torch to the “on” position. Oxyfuel has relatively slow. The user manual should contain a chart or table specifying the suggested amperage and air settings for various metal thicknesses. The following sections provide cut charts for each set of mechanized consumables. Cutting mild steel, stainless steel, and aluminum at 45 a with air using shielded. Web be sure to follow the plasma cutter settings and specifications in the cut. 60 amp mechanized shielded consumables. By matching the correct air pressure settings with the correct amperage settings for. The following sections provide cut charts for each set of mechanized consumables. Web cut charts the following cut charts provide the necessary information in order for the operator using the max200 machine torch system to be successful in plasma arc cutting. Explain. The cut charts are divided into two areas: To simplify the process of determining the appropriate plasma cutter settings, a plasma cutter settings chart can be utilized. 60 amp mechanized shielded consumables. Oxyfuel has relatively slow cutting speeds. Always start with the settings found in those charts and then make slight adjustments later if needed. Web all of our manuals contain very detailed cut charts, including plasma cut charts for stainless steel. Web using the cut charts. The user manual should contain a chart or table specifying the suggested amperage and air settings for various metal thicknesses. 60 amp mechanized shielded consumables. Comparing cutting speed and productivity, the plasma cutting system is much faster than. This chart provides a guideline for different material thicknesses, gas types, and desired cut qualities. Web plasma cutter settings chart. Install your consumables or hypertherm cartridge consumable onto your torch. Always start with the settings found in those charts. Cutting mild steel, stainless steel, and aluminum at 45 a with air using shielded. The following recommended settings are for mechanized cutting at 50 amps. It provides concise, accurate information about the thickness of different metals which can be cut using a. Web all of our manuals contain very detailed cut charts, including plasma cut charts for stainless steel. Down2earths10 september 18, 2020, 8:34pm 1. Cut charts are provided for each set of mechanized cutting and marking consumables. A plasma cutter amps thickness chart is an invaluable tool for anyone working with metal. Web the charts cover all the material thicknesses that can be cut with that system; Web by ethan maxwell / january 30, 2023. The following sections provide cut charts for each set of mechanized consumables. Web charts as needed to achieve optimal results for your cutting equipment and environment. Amperage, measured in amps, determines the intensity of the plasma arc.

Improve cut quality with these CNC steel and metal cutting tips

Razorcut 45 cut chart Plasma Cutters Langmuir Systems Forum

CNC Plasma

A check list for a plasma cutting table retrofit The Fabricator

Cut charts for everlast plasma 9 by hunterthehobbyist Plasma

CNC Plasma Cutting SV Seeker

Suggested Amperage & Air Setting For Plasma Cutter CUT50

.jpg)

FilePlasma Ball (short exposure).jpg Wikimedia Commons

Plasma Cutter Thickness Chart

A Comprehensive Buyer's Guide CNC Plasma Cutting Machine

Web Here Is How To Set Up A Plasma Cutter.

Explain Which Consumable Set To Use And At What Amperage;

Cut Charts Are Included For:

Depending On The Cutting Application, It Is Up To The Operator To Determine If The Tradeoffs Are Acceptable.

Related Post: