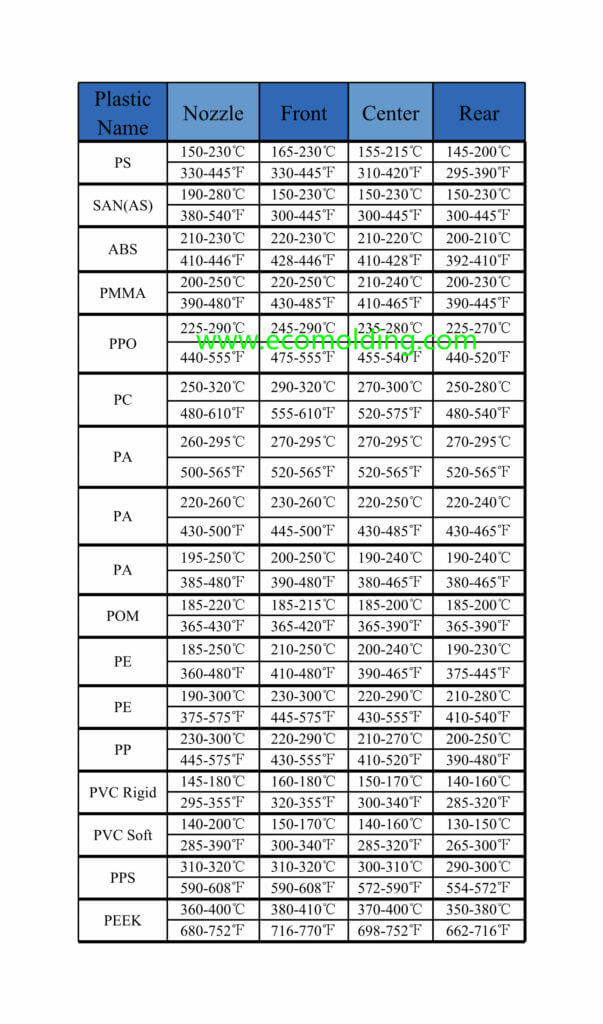

Plastic Melting Temperature Chart

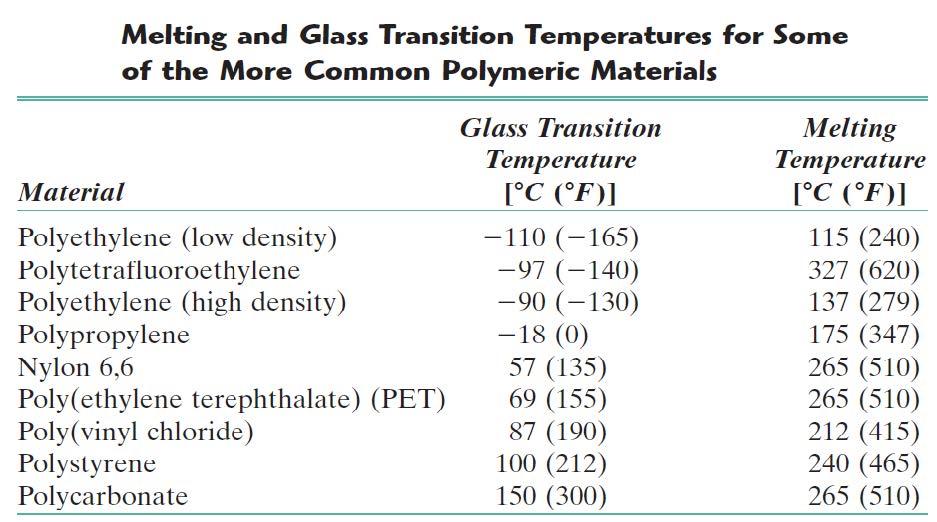

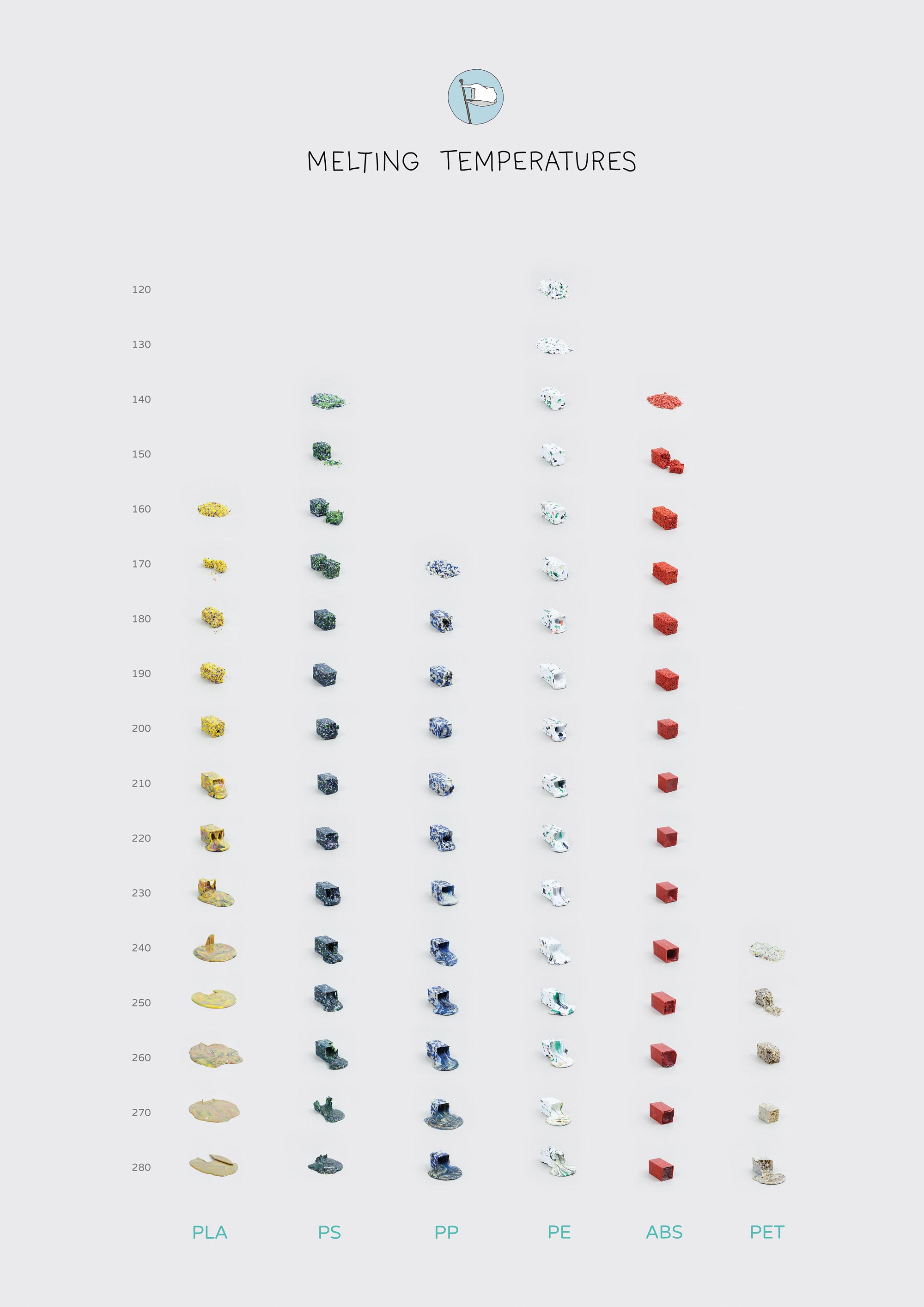

Plastic Melting Temperature Chart - However, different kinds of plastics have a specific melting temperature. Web melting point temperature range (0 c) glass transition temperature range (0 c) polyethylene (high density) abs tg: Web plastics short name plastic melting temperature range(℃) plastic mold temperature(℃) material drying temperature(℃) plastic drying hour (h) abs: Web the higher the melting point, the more resistant the plastic is to heat and other environmental factors. Web let’s explore the three states that plastics undergo during heating: Click on the tab of a specific property group. Take abs as an example, which melts at around 200°c (392°f). The melting point of acrylic is typically 160 °c. It is available in different crystalline structures, referred to as hdpe, ldpe, and lldpe. In order to melt the plastic in the oven you need a surface that will fit in the oven and will hold the plastic, even when it is melted. Web plastic melting temperature chart. The melting point of acrylic is typically 160 °c. Web plastic material selection guide (at curbell plastics) 1. Take abs as an example, which melts at around 200°c (392°f). The aim here is to inform you of the temperature necessary in the melting and molding of plastic products. In order to melt the plastic in the oven you need a surface that will fit in the oven and will hold the plastic, even when it is melted. Those with the widest melting range are easiest to weld. The melting point of plastic decreases if it is impure because of the presence of other compounds. It lists the ideal. The melting point of acrylic is typically 160 °c. It is available in different crystalline structures, referred to as hdpe, ldpe, and lldpe. Web let’s explore the three states that plastics undergo during heating: Web the higher the melting point, the more resistant the plastic is to heat and other environmental factors. Some can withstand temperatures up to 300°f (148°c),. The following chart will help you know the melting point of the. This commodity plastic is produced by addition or. View plastic materials found under a specific property group: The aim here is to inform you of the temperature necessary in the melting and molding of plastic products. Web for chemically resistant plastic, view our chemical resistance of plastics chart. Web plastic material selection guide (at curbell plastics) 1. Web plastics short name plastic melting temperature range(℃) plastic mold temperature(℃) material drying temperature(℃) plastic drying hour (h) abs: Web see below for our chart on plastic processing and drying temperatures, along with plastic and abs molding temperatures. Web as an injection mold manufacturer, w e will demonstrate mold and melt. Web may 19, 2023 by sagar habib. However, the melting point can vary due to. The glass transition temperature, melting temperature, flow temperature, and decomposition temperature. (320 °f) known by various names such as pmma (polymethyl methacrylate), plexiglass, and plexiglas, acrylic plastic is a transparent thermoplastic with impressive strength, rigidity, and optical clarity. The following chart will help you know. Web plastics short name plastic melting temperature range(℃) plastic mold temperature(℃) material drying temperature(℃) plastic drying hour (h) abs: Click on the tab of a specific property group. Get in the right group what is most important to the application? However, different kinds of plastics have a specific melting temperature. This table summarizes melting points of the most common materials. A homogenous melt is required for consistent part quality, but achieving it requires balancing a number of factors, including barrel usage and temperature as well as screw speed, backpressure and residence time. Web plastic material selection guide (at curbell plastics) 1. Web comprehensive guide on polyethylene (pe) polyethylene (pe) is one of the most popular thermoplastic materials. Web let’s explore. Get in the right group what is most important to the application? The melting point of plastic decreases if it is impure because of the presence of other compounds. Those with the widest melting range are easiest to weld. This helps in selecting the right thermoplastic for an application. • soften over a wide temperature range. Get in the right group what is most important to the application? View plastic materials found under a specific property group: The glass transition temperature, melting temperature, flow temperature, and decomposition temperature. The aim here is to inform you of the temperature necessary in the melting and molding of plastic products. The following chart will help you know the melting. The melting point of plastic decreases if it is impure because of the presence of other compounds. The melting point of ldpe is 105 degrees celsius, while that of hdpe is 125 degrees celsius. It is available in different crystalline structures, referred to as hdpe, ldpe, and lldpe. Web the higher the melting point, the more resistant the plastic is to heat and other environmental factors. Click the down or up arrows or column headings to sort plastic materials or material properties. It lists the ideal melt and mold temperatures for different types of plastics. To 1250c chch2 ch = chch2 ch polyacrylamide : Get in the right group what is most important to the application? Web let’s explore the three states that plastics undergo during heating: Here are some key properties and benefits of polypropylene: This table summarizes melting points of the most common materials you may encounter in your life. View plastic materials found under a specific property group: Please contact plastic service centers if you have any questions about processing and drying temperatures for plastic resins. Some can withstand temperatures up to 300°f (148°c), while. Web at temperatures between 392 and 536 degrees fahrenheit and 200 and 280 degrees celsius, various types of polypropylene melt. Polyethylene or ldpe & hdpe.Plastic Melting Temperature Chart My XXX Hot Girl

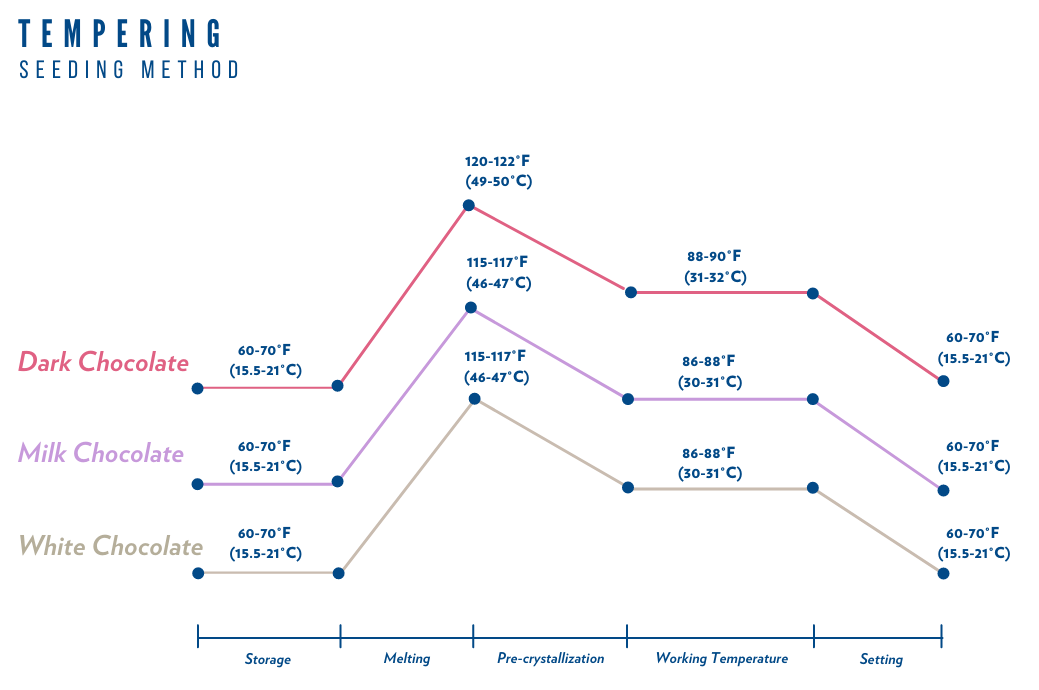

Zapatos Portero Puntero tempering chocolate temperatures chart

Injection Molding Material,Machine & Mold Temperature Information

The Basics of Plastic · Precious Plastic Toolbox

:max_bytes(150000):strip_icc()/Highperformance_thermoplastics_en-58d93d655f9b58468394f718.png)

Высокотемпературные термопласты teacherhistory.ru

Material Melt and Mould Temperature Chart PlastikCity

Plastic Melting Point Temperature PEEK Machining

Solved Table below shows the melting and glass transition

Melting temperatures of plastics. Download Scientific Diagram

Material Melting Point Chart

Web By The Extent Of Their Melting Range;

Explore The World Of Materials, Compare Materials With Each Other And Also Try To Explore Other Properties As Well.

1850 To 1950C Chs Polytetrafluoroethylene (Ptfe) Tm:

The Aim Here Is To Inform You Of The Temperature Necessary In The Melting And Molding Of Plastic Products.

Related Post: