Pulley Size Chart

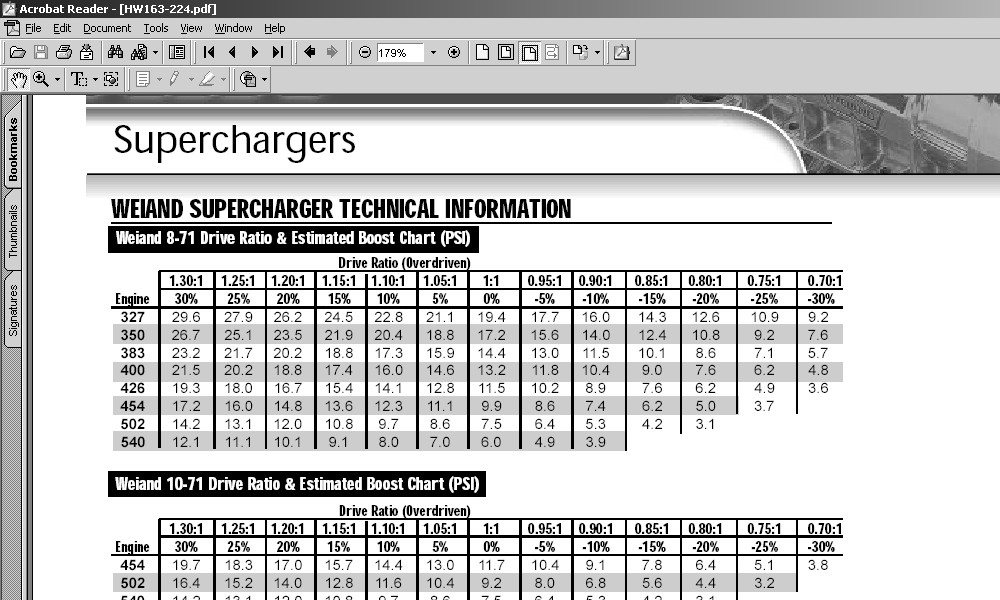

Pulley Size Chart - Measuring a v belt or flat pulley is easy. The hdd is available with various hub and bushing systems. 1 in = 25.4 mm. The basic formula for this calculation is: Properly sizing pulleys is important for a range of industries: V and flat belt design and engineering data. Most belt manufacturers will provide an online calculator for finding lengths of their belts, but the following formulas can be used to calculate belt length: Click on the images below to enlarge. Pump rpm motor pulley = motor rpm pump pulley you can achieve a more precise calculation, if required, by using the pitch diameter* of the pump and motor pulley. What is a timing pulley? To determine proper pulley size, use the calculator below. How to measure a pulley belt size. Pump rpm motor pulley = motor rpm pump pulley you can achieve a more precise calculation, if required, by using the pitch diameter* of the pump and motor pulley. Forces, acceleration, displacement, vectors, motion, momentum, energy of objects and more. Most belt manufacturers will. The basic formula for this calculation is: What is a timing pulley? Taper lock pulley aluminium, imperial: The effective tension te at the driver pulley is the sum of all individual forces resisting the belt motion. Taper lock pulley cast iron, metric. Terre products measuring guide explains pulley specs and dimensions. Calculating pulley rpm and speed: The following timing belt pulley pitch diameter (p.d.) and timing belt pulley outside diameter (o.d.) charts allow the end user to quickly determine the dimensional. Web learn how to measure your pulley or sheave. Steel rims, hubs and discs are fused into an integral component by. If you know any 3 values (pulley sizes or rpm) and need to calculate the 4th, enter the 3 known values and hit calculate to find the missing value. Pilot bore pulley aluminium, imperial: The following timing belt pulley pitch diameter (p.d.) and timing belt pulley outside diameter (o.d.) charts allow the end user to quickly determine the dimensional. How. 1 using an existing belt. Calculating pulley rpm and speed: V and flat belt design and engineering data. Web learn how to measure your pulley or sheave. Web motor and equipment speed for pulleys with different diameters are indicated in the charts below: N2 = d1 n1 / d2 (2) revolution of driver pulley. The basic formula for this calculation is: Forces, acceleration, displacement, vectors, motion, momentum, energy of objects and more. The effective tension te at the driver pulley is the sum of all individual forces resisting the belt motion. Web motor and equipment speed for pulleys with different diameters are indicated. Home > resources > pulley dimensional and identification guide. For timing pulleys, this is the measurement between the flanges. 38 speed ratios with standard pulley 1 using an existing belt. Outside diameter, or the distance across the pulley when measured between groove edges. Web pulley dimensional and identification guide. The effective tension te at the driver pulley is the sum of all individual forces resisting the belt motion. The belts, chains, or rope sizes that will fit into the pulley. Most belt manufacturers will provide an online calculator for finding lengths of their belts, but the following formulas can be used to calculate. The hdd is available with various hub and bushing systems. The basic formula for this calculation is: V and flat belt design and engineering data. Web learn how to measure your pulley or sheave. Forces, acceleration, displacement, vectors, motion, momentum, energy of objects and more. N2 = d1 n1 / d2 (2) revolution of driver pulley. Steel rims, hubs and discs are fused into an integral component by a continuous submerged arc welded bond that maximizes pulley strength, balance and concentricity. Home > resources > pulley dimensional and identification guide. Web we ease the task of choosing the best pulley for an application: V and. Aerospace, agriculture, manufacturing, pharmaceutical, automotive, and robotics, just to name a few. Web pulley dimensional and identification guide. A timing pulley is a mechanical component used in various machinery and equipment. Most belt manufacturers will provide an online calculator for finding lengths of their belts, but the following formulas can be used to calculate belt length: The effective tension te at the driver pulley is the sum of all individual forces resisting the belt motion. How to calculate pulley size from rpm. Pilot bore pulley aluminium, imperial: Steel rims, hubs and discs are fused into an integral component by a continuous submerged arc welded bond that maximizes pulley strength, balance and concentricity. Web 1 1 1/8 1 3/16 1 1/4 1.374 for use with. 2 finding the size using the pulleys. N2 = d1 n1 / d2 (2) revolution of driver pulley. 1 in = 25.4 mm. Terre products measuring guide explains pulley specs and dimensions. Pump rpm motor pulley = motor rpm pump pulley you can achieve a more precise calculation, if required, by using the pitch diameter* of the pump and motor pulley. 38 speed ratios with standard pulley It is used to synchronize movement and ensure that multiple moving parts function together.

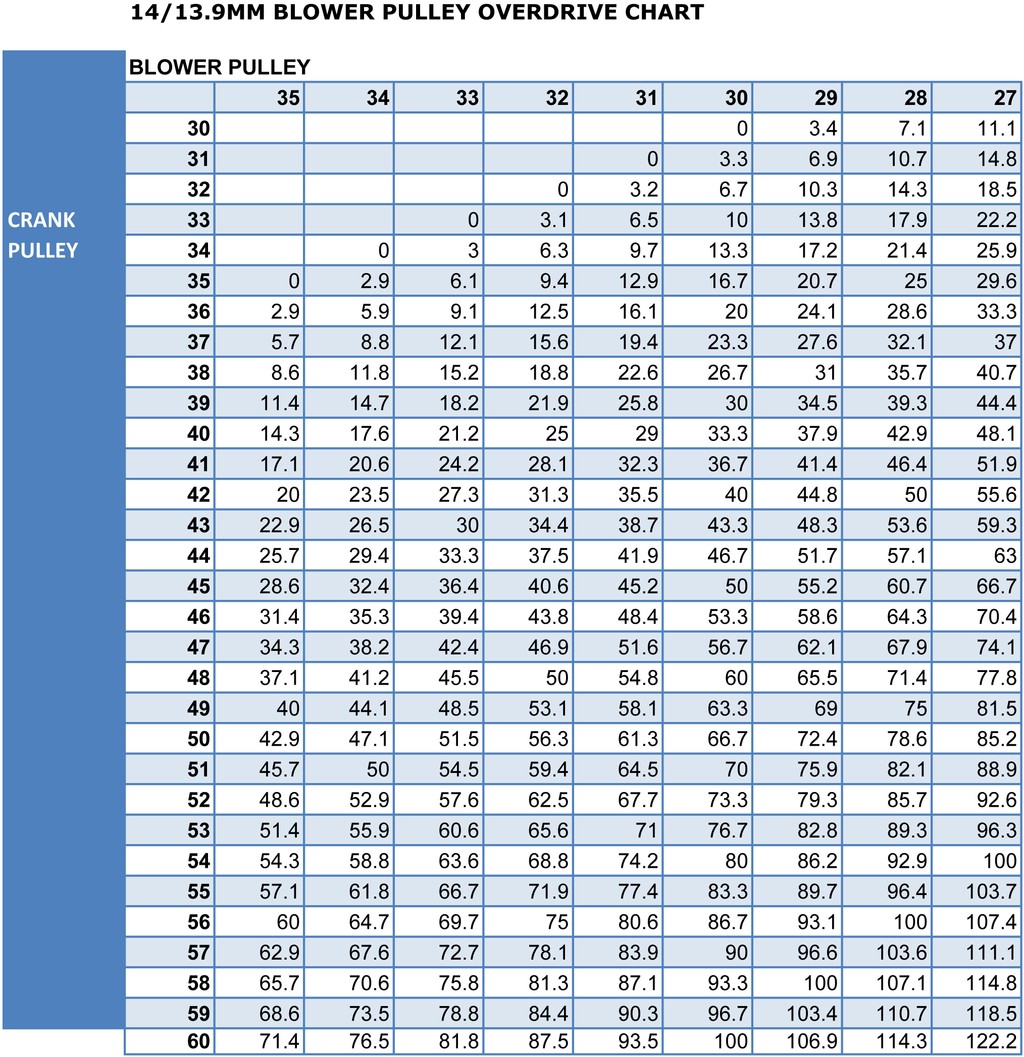

14/13.9mm Blower Pully Chart

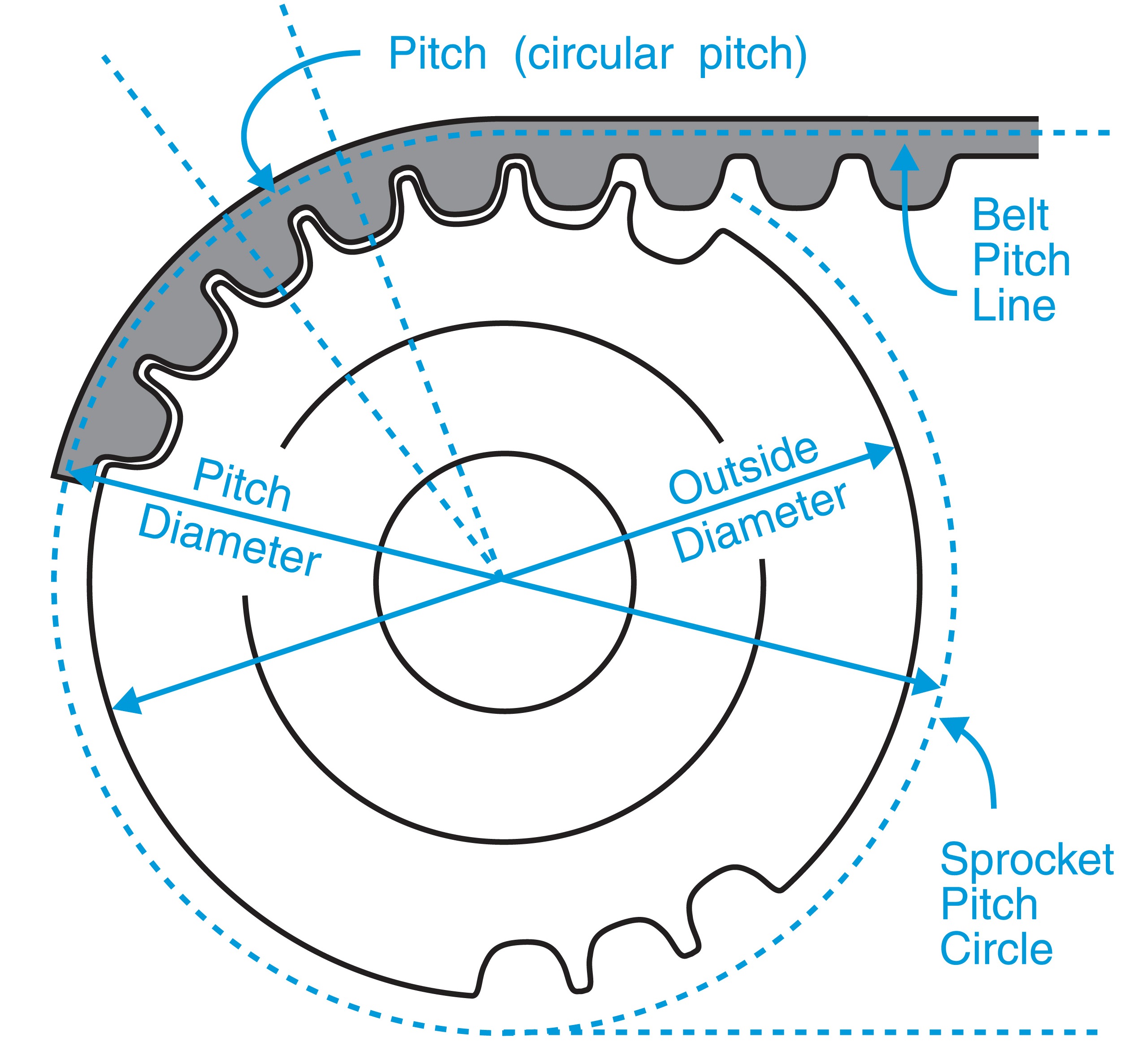

Timing Belt Pulley Diameter Charts Pfeifer Industries

Pulley Size Chart for Swaps Snowblower Forum

Pulley catalog1105low

Pulley Belt RPM Calculator Herramienta de mano, Trabajo de metal

Minimum Pulley Diameter Chart Davis Industrial

Dimensions of dual pulley/sheave for 50hz 10L running 1415rpm

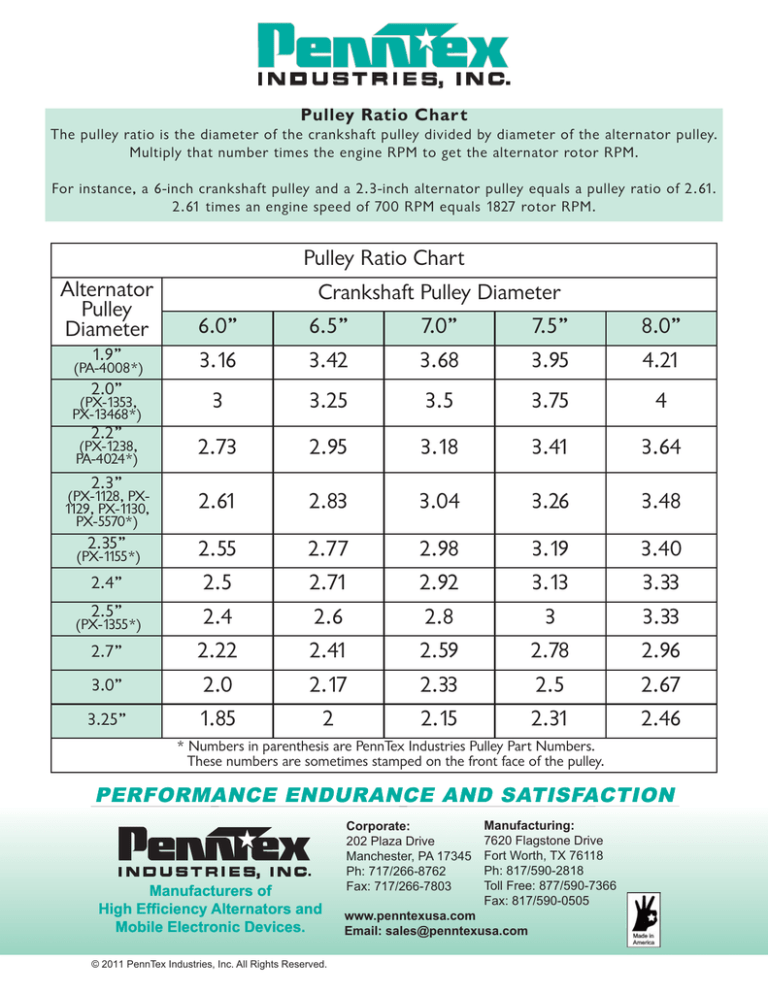

Pulley Ratio Chart

990360 Aluminum Motor Belt Wheel Pulley Single Groove Several Sizes

blower pulley size charts

If You Know Any 3 Values (Pulley Sizes Or Rpm) And Need To Calculate The 4Th, Enter The 3 Known Values And Hit Calculate To Find The Missing Value.

Web With Our Timing Pulley Size Chart, You Can Easily Find The Perfect Timing Pulley For Your Needs.

Home > Resources > Pulley Dimensional And Identification Guide.

Web We Ease The Task Of Choosing The Best Pulley For An Application:

Related Post: