Reamer Size Chart

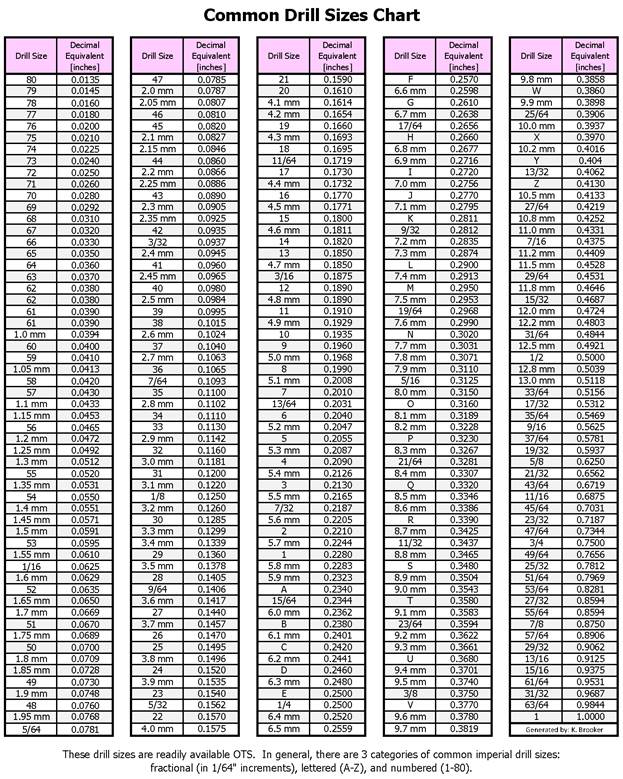

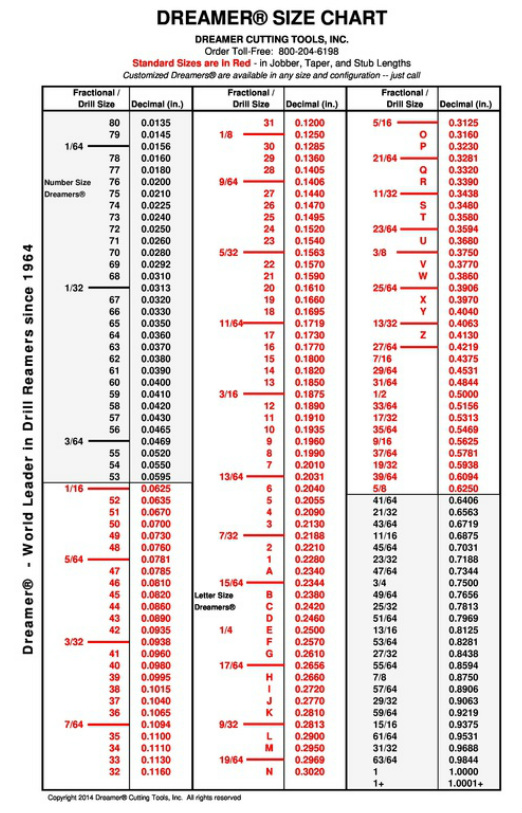

Reamer Size Chart - Selecting the correct drill size is also important as doing so will prolong the life of your reamer and ensure proper size and finish. Web reamer selection guide for small & medium hdd drills. Web use these charts for carbide tipped reamers. Web pre ream drill size chart. Intended for use in drill presses, lathes and screw machines. American national standard taper pins. The hole that will be reamed must first be drilled to an undersized diameter. Decimal (in.) fractional / drill size. Typically, the rule of thumb is to keep 0.010″ to 0.015″ material after drilling for the reamer to remove. Ford® stocks over 900 inch and metric size Web true size® reamers can be used with confidence. 28 hannibal carbide tool, inc. Decimal (in.) fractional / drill size. Typically, the rule of thumb is to keep 0.010″ to 0.015″ material after drilling for the reamer to remove. American national standard taper pins. Basic technical information for reamers. A 10 taper pin 6” long would require 3 drills to prepare the hole for reaming as shown below. Selecting the correct drill size is also important as doing so will prolong the life of your reamer and ensure proper size and finish. Decimal (in.) fractional / drill size. Complete family of standard and metric. Decimal (in.) fractional / drill size. Web what is a reamer & what is reaming? Web use these charts for carbide tipped reamers. As the complexity of manufactured products intensifies, so does the need to create consistent, highly tolerant holes. Size by (mm) reduce drill hole. American national standard taper pins. Stock removal is an important aspect of reaming however we encourage you to review our previous blogs as we tie together all of the elements of the reamed hole. Decimal (in.) fractional / drill size. Web pre ream drill size chart. Selecting the correct drill size is also important as doing so will prolong the. Hole saw trim speed (rpms) recommendations · metric tap drill sizes · reaming recommendations · screw thread guide · screw thread pitch diameter detection. Selecting the correct drill size is also important as doing so will prolong the life of your reamer and ensure proper size and finish. Web selecting the correct reamer diameter is not quite as simple as. Stock removal is an important aspect of reaming however we encourage you to review our previous blogs as we tie together all of the elements of the reamed hole. Hole saw trim speed (rpms) recommendations · metric tap drill sizes · reaming recommendations · screw thread guide · screw thread pitch diameter detection. This information is specifically aimed at selecting. Stock removal is an important aspect of reaming however we encourage you to review our previous blogs as we tie together all of the elements of the reamed hole. Web these versatile tools ensure accurate sizing, smooth finishes, and proper alignment for a variety of applications. Web reamer selection guide for small & medium hdd drills. Selecting the correct drill. There are 3 steps involved in selecting the correct yankee reamer and drill size for your application: Ideally a reamer should run within.001” tir Web use these charts for carbide tipped reamers. Reamers are the perfect solution for enlarging or finishing an existing hole to a specific size and tolerance. If you require learn correction for straightness than that, boring. Web pre ream drill size chart. Web sizes 6 to 10 will need 3 sizes of drills to prepare hole for reaming. Intended for use in drill presses, lathes and screw machines. There are 3 steps involved in selecting the correct yankee reamer and drill size for your application: Hole diameter you are drilling in inches. Web pre ream drill size chart. Selecting the correct drill size is also important as doing so will prolong the life of your reamer and ensure proper size and finish. Web a 1/4″ reamer has improve of straightness of a hole through increase to 0.005″, but no more. Ideally a reamer should run within.001” tir Web sizes 6 to 10. Web what is a reamer & what is reaming? Think about the diameter of your pipe, including the ends where two pieces slip together. Hole diameter you are drilling in inches. The hole that will be reamed must first be drilled to an undersized diameter. As the complexity of manufactured products intensifies, so does the need to create consistent, highly tolerant holes. Typically, the rule of thumb is to keep 0.010″ to 0.015″ material after drilling for the reamer to remove. There are 3 steps involved in selecting the correct yankee reamer and drill size for your application: 1/4 5/8 4 1/4 41/2 51/8 53/8 55/8 57/8 65/8 67/8 71/8 71/2 81/8 91/4 101/4 111/4 12 141/4 155/8 16 18 185/8 20 231/8 231/2 271/8 0.1250 0.1560 0.1710 0.1870 0.2180 0.2640 Web reamer to hole size chart. This chart allows for drill oversize based on study done by the united states cutting tool institute. < back to technical information. Size by (mm) reduce drill hole. American national standard taper pins. 28 hannibal carbide tool, inc. Ford® stocks over 900 inch and metric size Selecting the correct drill size is also important as doing so will prolong the life of your reamer and ensure proper size and finish.

Standard Reamer Size Chart Best Picture Of Chart

Chucking Reamer High Speed Steel Metric Size Range 2.50 to 25.0 mm

Standard Reamer Size Chart Best Picture Of Chart

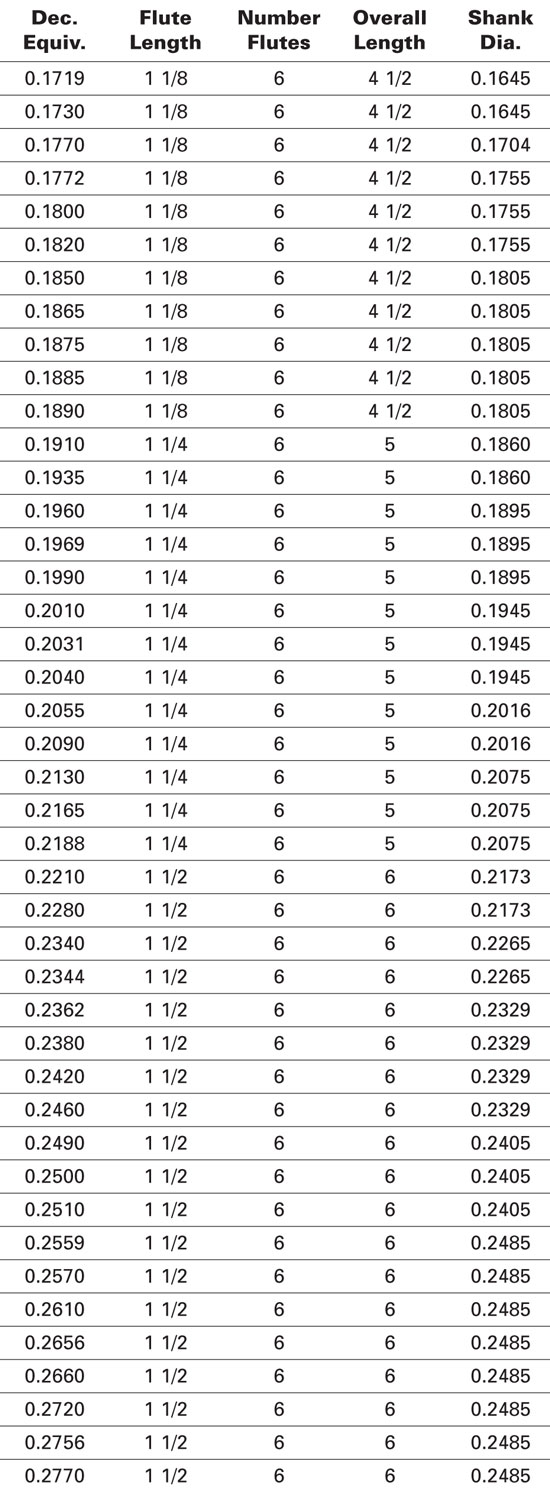

Reamer Dimensions for .1719 .2810" Diameters Cutting Tool

Standard Reamer Size Chart Best Picture Of Chart

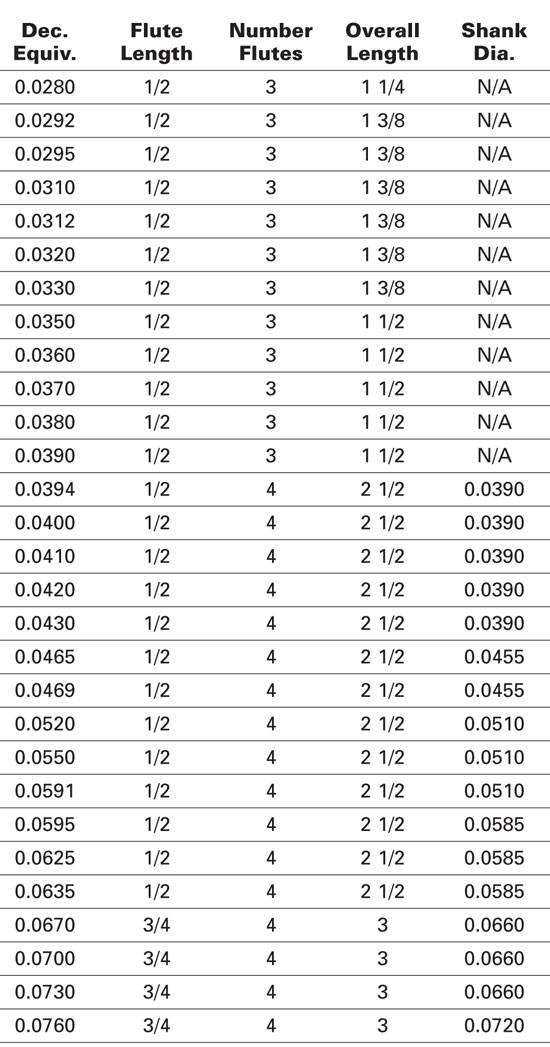

Chucking Reamer Size Chart

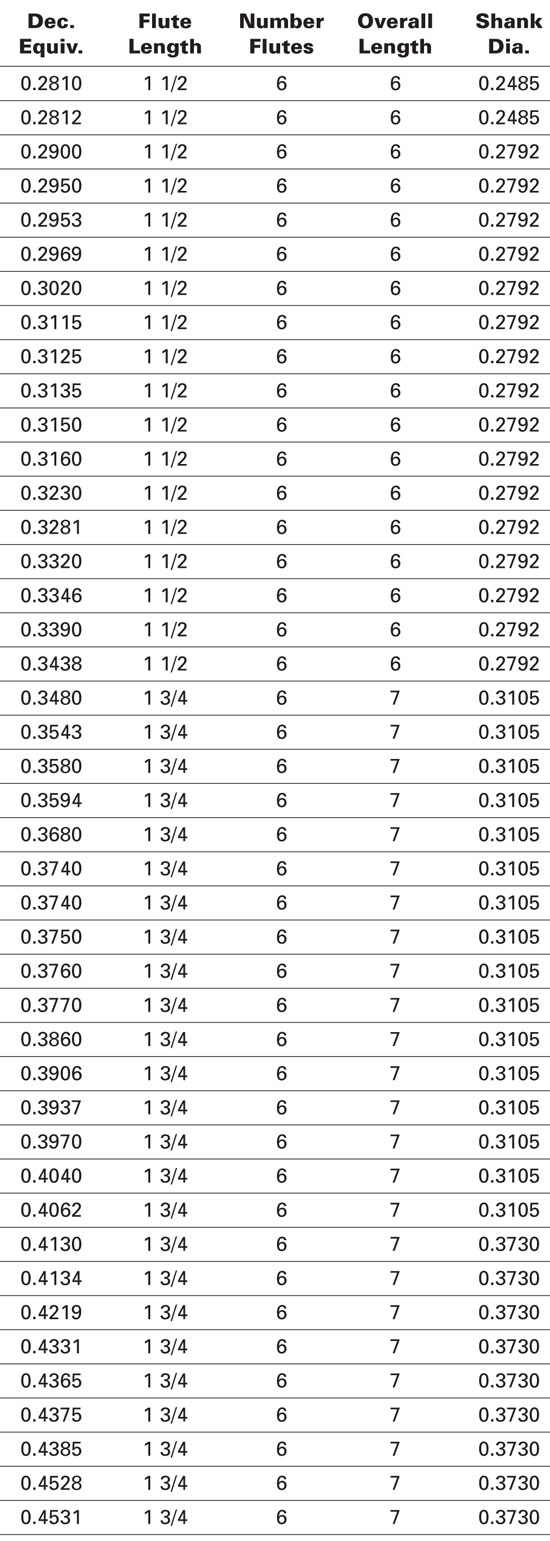

Reamer Dimensions for .2810" .4687" Diameters Cutting Tool

Standard Reamer Size Chart Best Picture Of Chart

Standard Reamer Size Chart Best Picture Of Chart

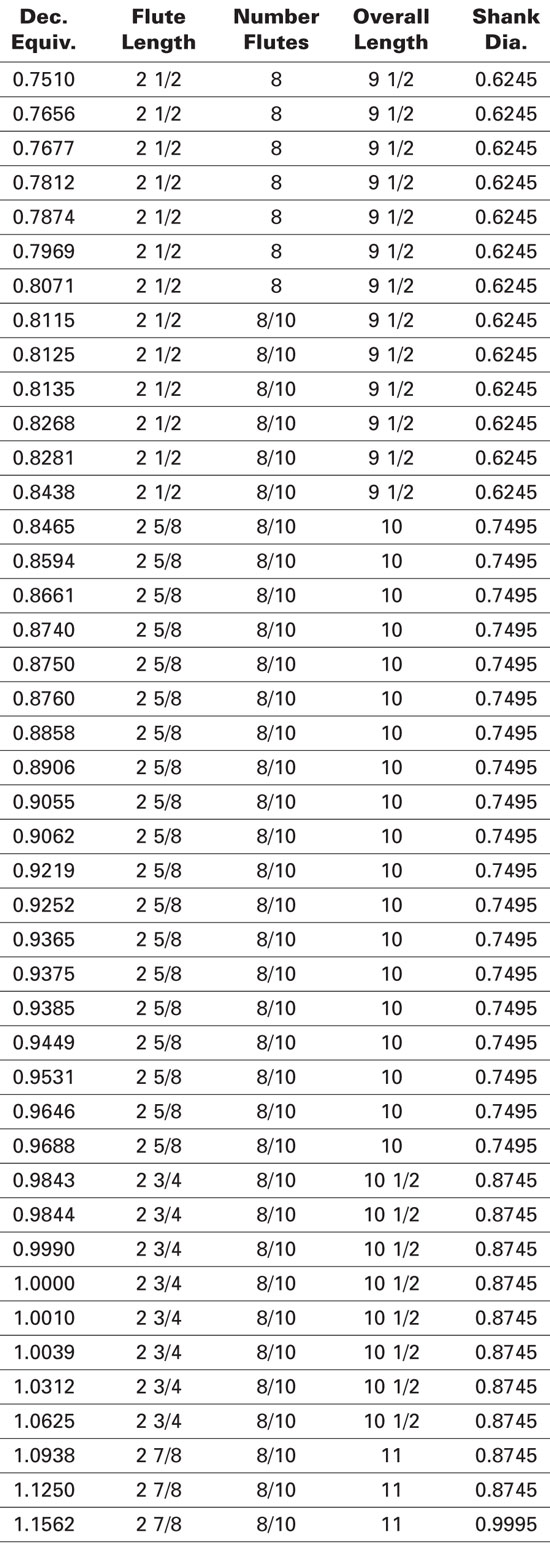

Reamer Dimensions for .7510" 1.1810" Diameters Cutting Tool

Complete Family Of Standard And Metric Sizes M.a.

Ideally A Reamer Should Run Within.001” Tir

Stock Removal Is An Important Aspect Of Reaming However We Encourage You To Review Our Previous Blogs As We Tie Together All Of The Elements Of The Reamed Hole.

A 10 Taper Pin 6” Long Would Require 3 Drills To Prepare The Hole For Reaming As Shown Below.

Related Post: