Refrigerant Flow Chart

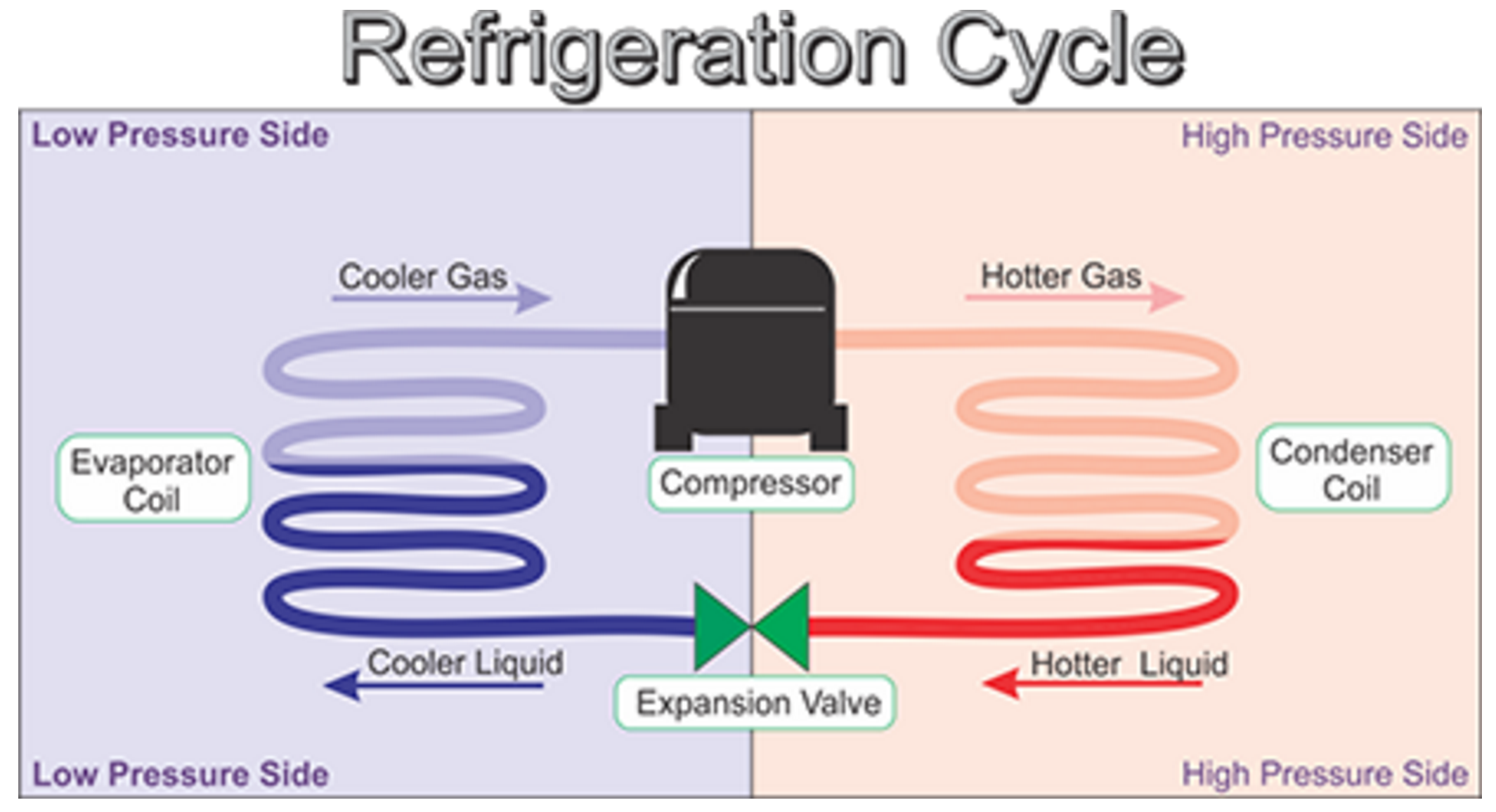

Refrigerant Flow Chart - Normal pressure ranges and what they mean. Collection of guidance documents concerning section 608 leak repair requirements for industrial process refrigeration. The compressor can be thought of as the heart of the process. Suva refrigerants ® section 1. Steps to measure refrigerant pressure. Web flowchart for the refrigeration cycle. Pt chart (pdf) forane ® pt iphone® app. The second energy input is electrical energy flowing into the compressor whenever it is operating. Short tube length ranged from 9.5 mm to 25.4 mm, and sharp edged diameters ranged from 1.09 mm to 1.94 mm. Web refrigerant leak repair flow chart go to pg. Web refrigerant leak repair flow chart (pdf) (785.2 kb) self audit checklist (pdf) (154.1 kb) contact us to ask a question, provide feedback, or report a problem. Suva refrigerants ® section 1. Web refrigerant leak repair flow chart go to pg. For refrigeration problems, a magnetically attractive solution. Web tools for measuring refrigerant pressure. It acts like a pump to create the circulation by compressing the refrigerant gas, creating a pressure difference that drives the refrigerant around the circuit in a continuous cycle. The cooling medium can also be water. Web review the fundamentals of heat transfer and thermodynamics before you check refrigerant pressures. Web refrigerant leak repair flow chart go to pg. Download. Learn refrigerant flow in a vapor compression system using a schematic of various components and a pressure enthalpy. Reading the gauge or sensor display. Last updated on september 11, 2023. Web tools for measuring refrigerant pressure. Conventional and magnetic refrigeration cycles use different physical effects to cool things off. The hot gas discharge line must: Leak opbon repair leaks sufficient to lower leak rate below 15% annually (35% for commercial) within 30 days of discovery. Conventional and magnetic refrigeration cycles use different physical effects to cool things off. 194k views 10 years ago refrigeration. Web refrigerant flow as descibed by prof. Web review the fundamentals of heat transfer and thermodynamics before you check refrigerant pressures. Hvac air / refrigerant diagnostic quick sheet. Preparing the system for measurement. Web refrigerant flow as descibed by prof. Web use the following property data, flow chart and properties to help you understand the basics when working with refrigerants. Use this pdf for all your pressure/temperature needs. Web flowchart for the refrigeration cycle. Short tube length ranged from 9.5 mm to 25.4 mm, and sharp edged diameters ranged from 1.09 mm to 1.94 mm. Learn refrigerant flow in a vapor compression system using a schematic of various components and a pressure enthalpy. Pt chart (pdf) forane ® pt iphone®. Reading the gauge or sensor display. 194k views 10 years ago refrigeration. End y start is the normal charge of the refrigeration system > 50 lbs? (2) high pressure hot vapor from the compressor goes into the condensor. This investigation examined mass flowrate of r12, r134a, r502, r22, r407c, and r410a through short tubes. The pressure is usually measured in units like psi, kpa, or bar, while the enthalpy is measured in units like btu/lb, kj/kg, or kcal/kg. Web refrigerant leak repair flow chart go to pg. This white paper describes the requirements, advantages and opportunities associated with specifying and applying variable refrigerant flow (vrf) systems and addresses common misconceptions professionals may encounter in. Collection of guidance documents concerning section 608 leak repair requirements for industrial process refrigeration. • avoid oil trapping at minimum system capacity. Web refrigerant flow as descibed by prof. Web refrigerant leak repair flow chart (pdf) (785.2 kb) self audit checklist (pdf) (154.1 kb) contact us to ask a question, provide feedback, or report a problem. Preparing the system for. Web refrigeration cycle flow chart. • dampen or eliminate line vibration and noise caused by gas pulsations and compressor vibration. Theoretical performance analysis of an r1234yf refrigeration cycle based on the effectiveness of internal heat exchanger. Preparing the system for measurement. Web review the fundamentals of heat transfer and thermodynamics before you check refrigerant pressures. Web refrigeration cycle flow chart. End y start is the normal charge of the refrigeration system > 50 lbs? Hvac air / refrigerant diagnostic quick sheet. Progression toward sustainable refrigeration products. Web refrigerant leak repair flow chart go to pg. (ac) (lt, mt, ac) hcfcs hfcs. Web refrigerant flow as descibed by prof. Additional refrigeration information and resources are located below the chart. The pressure is usually measured in units like psi, kpa, or bar, while the enthalpy is measured in units like btu/lb, kj/kg, or kcal/kg. The second energy input is electrical energy flowing into the compressor whenever it is operating. Theoretical performance analysis of an r1234yf refrigeration cycle based on the effectiveness of internal heat exchanger. Use this pdf for all your pressure/temperature needs. • avoid oil trapping at minimum system capacity. • dampen or eliminate line vibration and noise caused by gas pulsations and compressor vibration. Web most modern condensers flow air over the tubing where the refrigerant is flowing—the heat transfers out of the refrigerant and into the air. Progression toward sustainable refrigeration products.

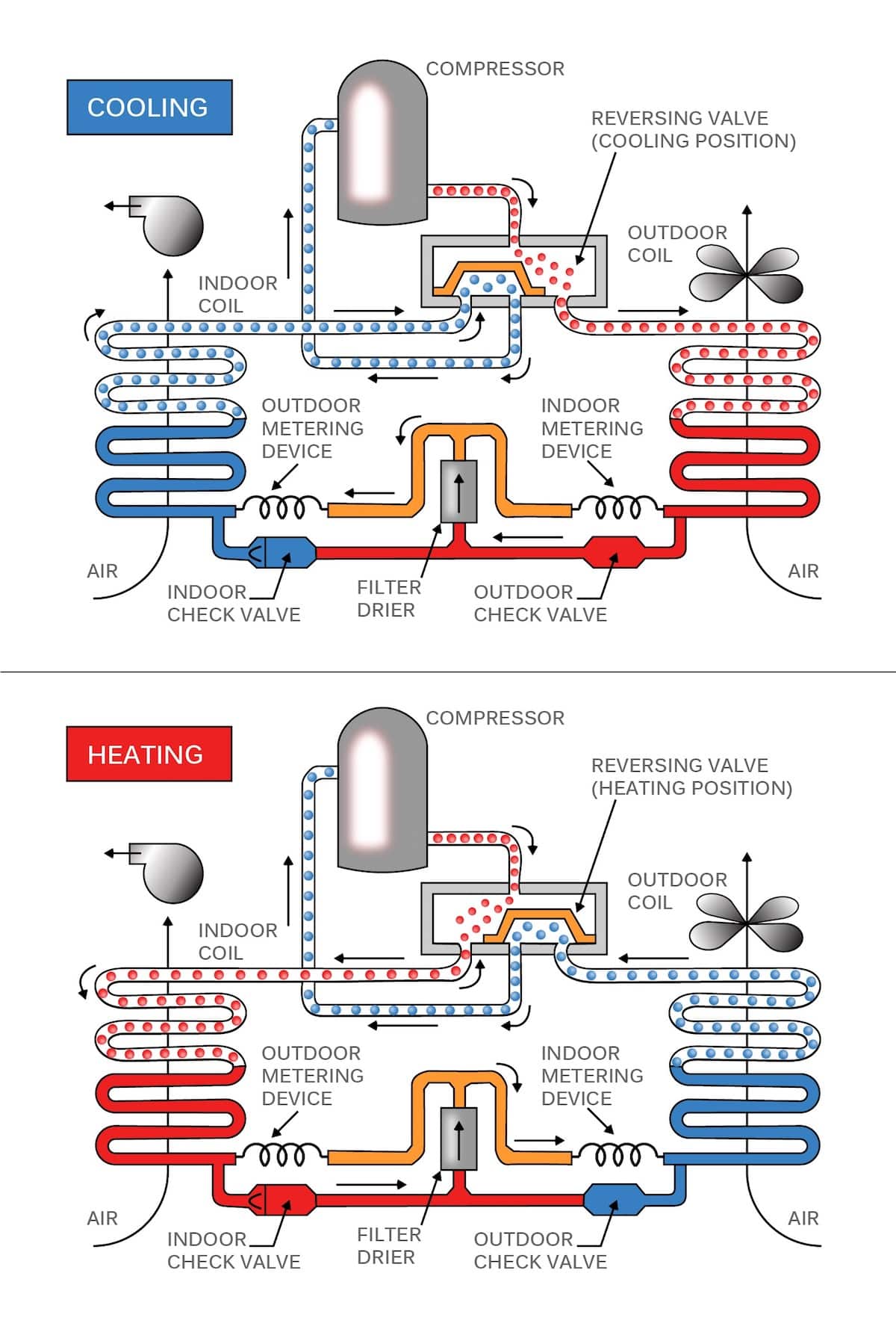

Heat Pump Refrigerant Flow Chart

Refrigeration Cycle Tutorial Step by Step, Detailed and Concise! YouTube

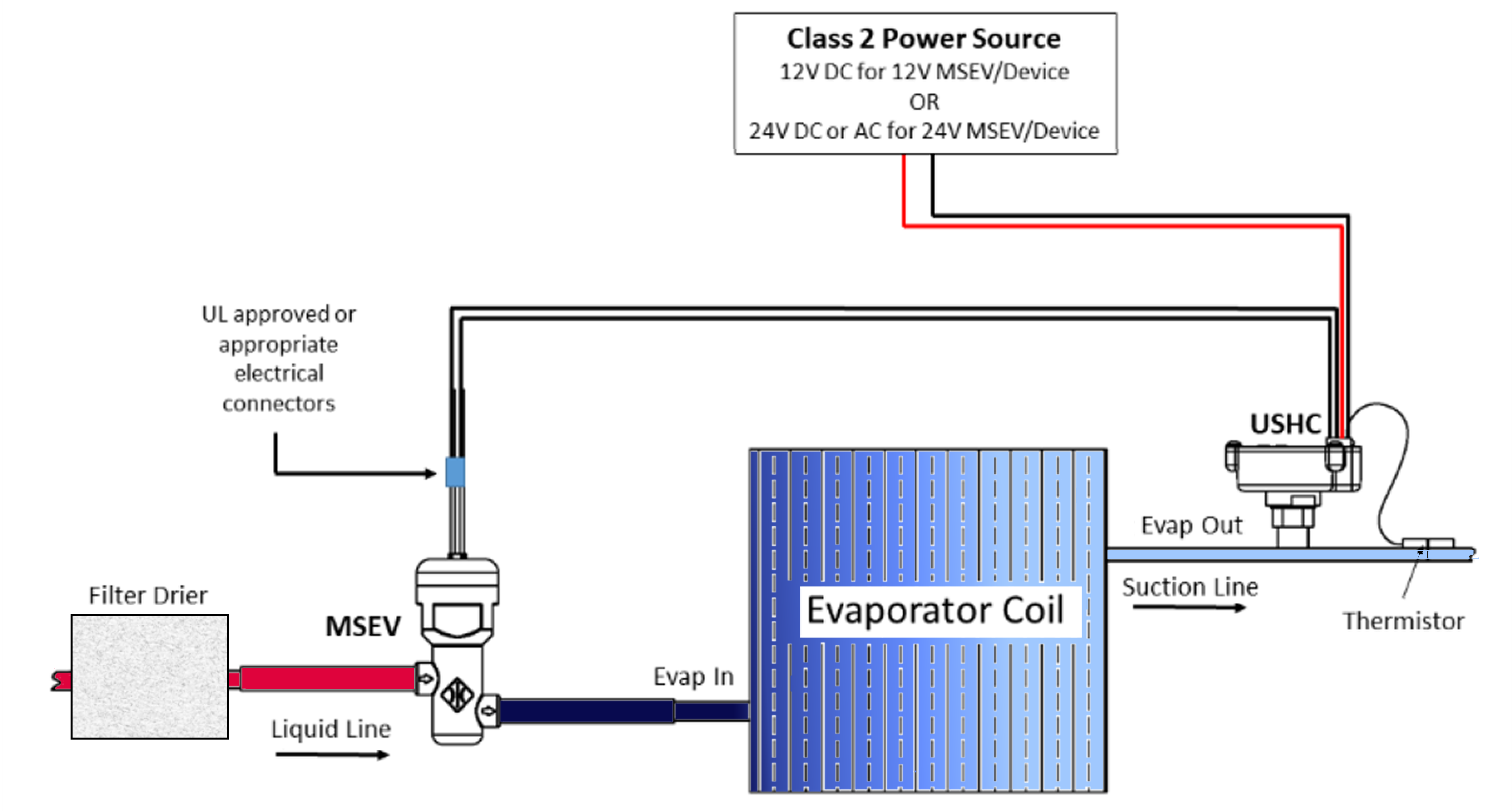

Refrigerant Flow Control Technology DunAn Microstaq, Inc.

Variable Refrigerant Flow Harvey Norman Commercial Air Conditioning

refrigerant types The Engineering Mindset

HVAC Refrigeration Cycle Diagram

Refrigerant Flow Control Technology DunAn Microstaq, Inc.

Basic Refrigeration System. Refrigerant flow презентация онлайн

The Future of Refrigeration Hillphoenix

Figure 15 Refrigerant flow diagram.

Web Flowchart For The Refrigeration Cycle.

Steps To Measure Refrigerant Pressure.

Temperature And Pressure Charts For.

(2) High Pressure Hot Vapor From The Compressor Goes Into The Condensor.

Related Post: