Sandblast Media Chart

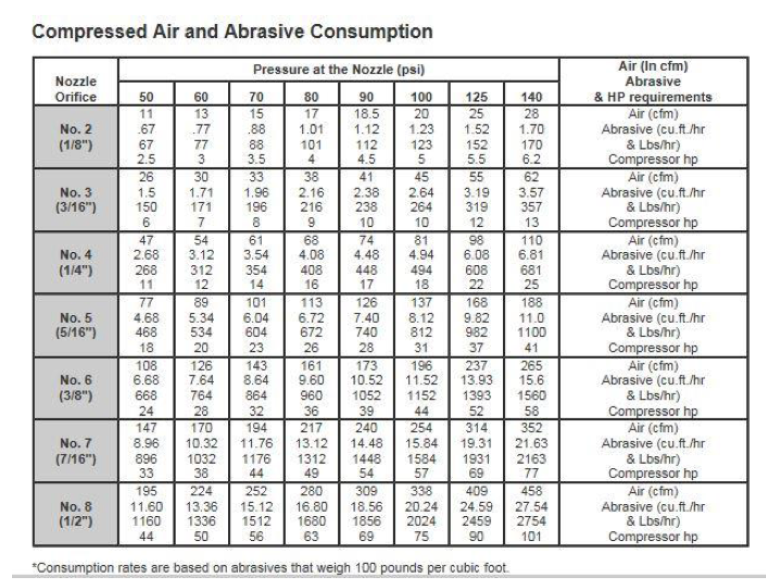

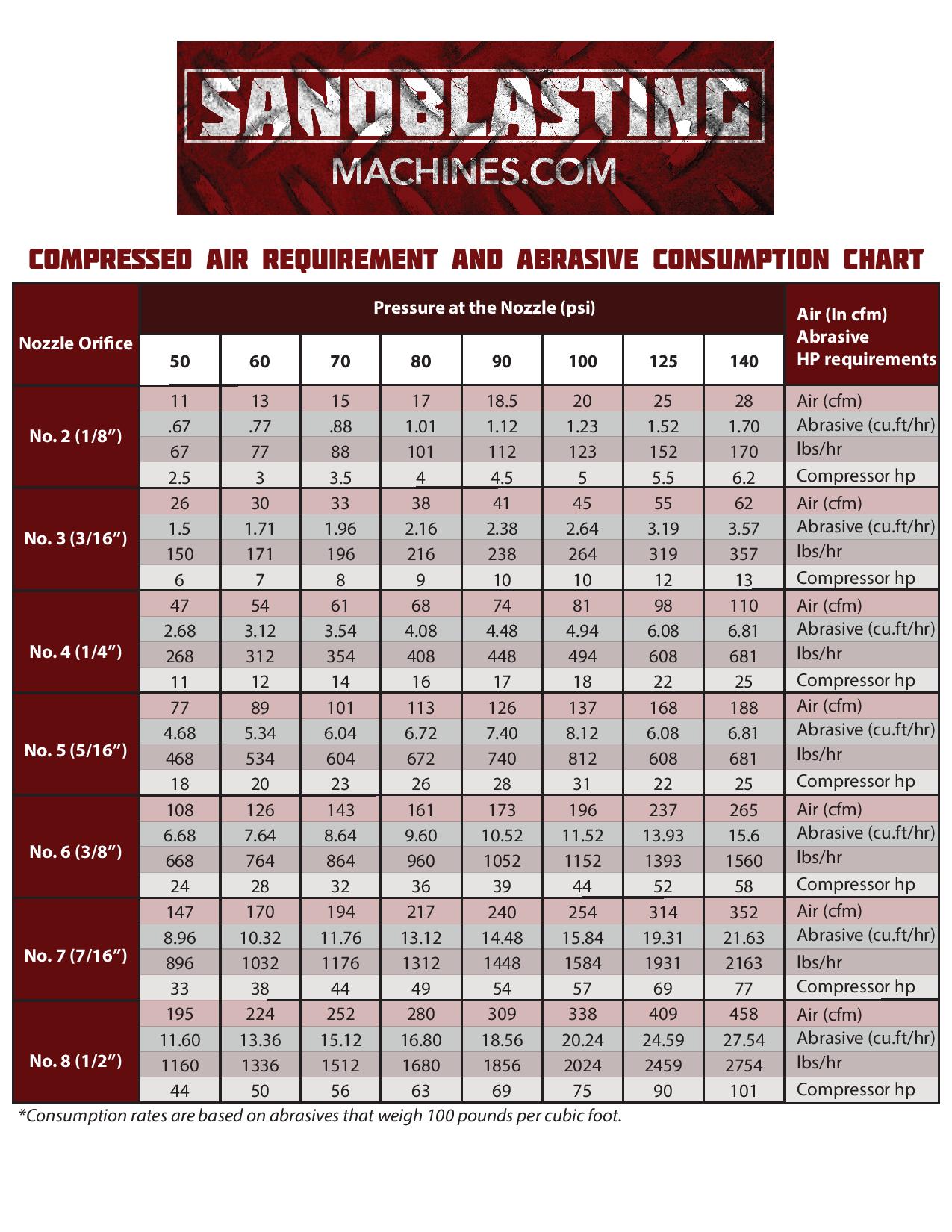

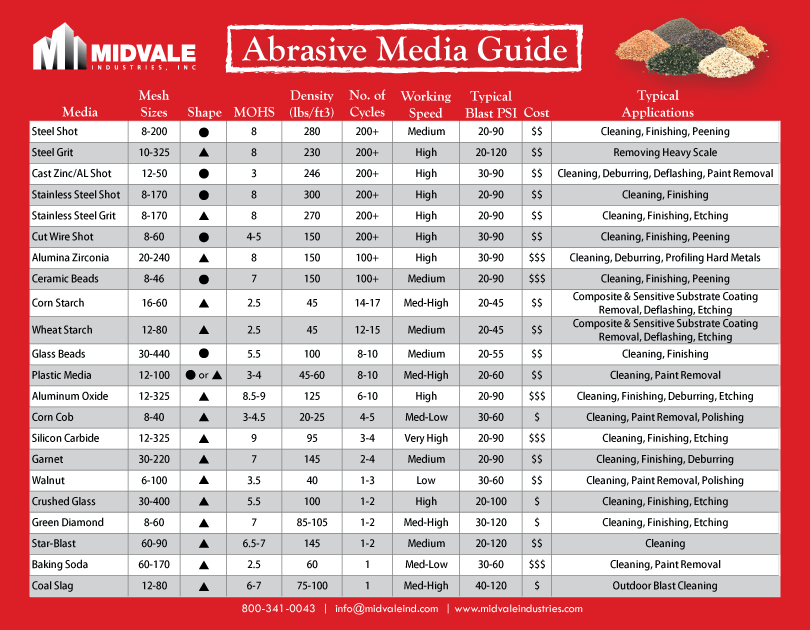

Sandblast Media Chart - Glass bead blasting what is. Rounded abrasives create a dimpled profile, like the surface of a golf ball. This chart compares the most common abrasives for. E ach abrasive has a listed hardness value, surface profile, surface removal ability, and velocity (if the blasting media travels at a high speed or a low speed from the blast pot's compressed air). Play sand is not an industrial product, so it's not controlled and graded the way abrasives are. When you are sandblasting material, make sure it is done correctly. Web shop for sandblasting media at tractor supply co. Focusing on a wide variety of sand blaster media and abrasives blast media for cleaning and surface preparation. Whether you’re restoring an antique car, cleaning a ship’s hull, or preparing a metal surface for a fresh coat of paint, choosing the right abrasive media is the key to a successful sandblasting project. Web sandblasting is most often used for surface preparation, cleaning, and finishing tasks. Covers glass bead, aluminum oxide, silicon carbide sand & walnut shell This chart compares the most common abrasives for. When you are sandblasting material, make sure it is done correctly. 16/20, 1240 = minimum nozzle bore size of 1/4″. Automatic valves, on the other hand, have a mechanism to shut off the flow of abrasive. Web the blasting media selection guide below contains a list of the common blasting media and the differences in blasting media. Covers glass bead, aluminum oxide, silicon carbide sand & walnut shell These differences will vary the surface finish results, the media reusability, and cost. 16/20, 1240 = minimum nozzle bore size of 1/4″. = manufactured *consult osha regulations before. Web sandblasting is most often used for surface preparation, cleaning, and finishing tasks. Web sandblasting media chart. The sandblasting media needed for your sandblasting operation vary in hardness, mesh sizes, density, shape, and hardness. As a general rule, your nozzle orifice should be 3 times the size of the grit, minimum. Web this complete blasting media guide contains a list. Web as soon as you have the appropriate blasting media, you can obtain the outcomes you want with every project every time. 16/20, 1240 = minimum nozzle bore size of 1/4″. Web abrasive blasting media vary dramatically in particle size, hardness, shape, and other properties. Web the choice of sandblast media considers factors such as the hardness and density of. Web sandblasting is most often used for surface preparation, cleaning, and finishing tasks. Web the below charts show a few types of abrasive used in dry media blasting. Each type of media has its unique properties and applications, making it crucial to select the appropriate one for each project. The sandblasting media needed for your sandblasting operation vary in hardness,. Web blast media chart. Web the blast media type, shape, size, density, and hardness, along with media acceleration and volume of media, combined with blasting distance from the workpiece, angle of impact and time cycles are important factors in the blast process capabilities. The sandblasting media needed for your sandblasting operation vary in hardness, mesh sizes, density, shape, and hardness.. Web the below charts show a few types of abrasive used in dry media blasting. 3060 grit = minimum nozzle bore size of 1/8″. Web when it comes to metering valves, there are two types: An 8 grit is much coarser than a 360 grit. Web media blasting basics compressed air basics (this chart is only a guideline. Web this sandblasting media guide shows the many blast media types available. As a general rule, your nozzle orifice should be 3 times the size of the grit, minimum. Aluminum oxide | plastics | glass bead | steel shot & steel grit | ceramic shot & ceramic grit | cut wire shot | baking soda aluminum oxide aluminum oxide is. Below are charts of air volume (scfm) used in blasting with pressure and suction systems utilizing various pressures (psi) and orifice sizes. These differences play a huge role in determining how effective your media are. Easily see microns to grit size. The chart below details some of these differences and. Web the blasting media selection guide below contains a list. Whether you’re restoring an antique car, cleaning a ship’s hull, or preparing a metal surface for a fresh coat of paint, choosing the right abrasive media is the key to a successful sandblasting project. Manual valves do not have a shutoff to stop the flow of abrasive. Media blasting (also called sandblasting or abrasive blasting) has many uses, from removing. Web handy sandblasting grit conversion chart for grit size, uss mesh, microns, and inches. These differences play a huge role in determining how effective your media are. 16/20, 1240 = minimum nozzle bore size of 1/4″. Web this sandblasting media guide shows the many blast media types available. Web sandblasting is most often used for surface preparation, cleaning, and finishing tasks. Web media blasting basics compressed air basics (this chart is only a guideline. Web a finer 240 grit will pass through a screen with 240 smaller holes in the same 1″ square mesh. Web the blast media type, shape, size, density, and hardness, along with media acceleration and volume of media,. Web the blast media type, shape, size, density, and hardness, along with media acceleration and volume of media, combined with blasting distance from the workpiece, angle of impact and time cycles are important factors in the blast process capabilities. The sandblasting media needed for your sandblasting operation vary in hardness, mesh sizes, density, shape, and hardness. It won't behave predictably in your equipment, and you could wind up in loads of legal trouble, from the epa to local municipalities. Rounded abrasives create a dimpled profile, like the surface of a golf ball. 2040 = minimum nozzle bore size of 3/16″. Web blast media chart. Blast media characteristics comparison = angular; Web sandblasting media chart.

How to Sandblast Sandblast, Sandblasting, Sodablast, Sodablasting

Choosing the Right Blast Media for Abrasive Blasting

Info Tools Raptor Blasting Solutions

Essential Criteria for Brazing Item 2 Proper cleaning—role of grit

Glass Beads for SandblastingLangfang Olan Glass Beads Co., Ltd Olan

Compressed Air Application Sandblasting/Abrasive Blasting

Understanding Sandblasting Compressor Size Requirements Sandblasting

Chart for Compressed Air and Sandblasting Stone Accessories

7 Things You Should Be Doing When Sandblasting Midvale Industries

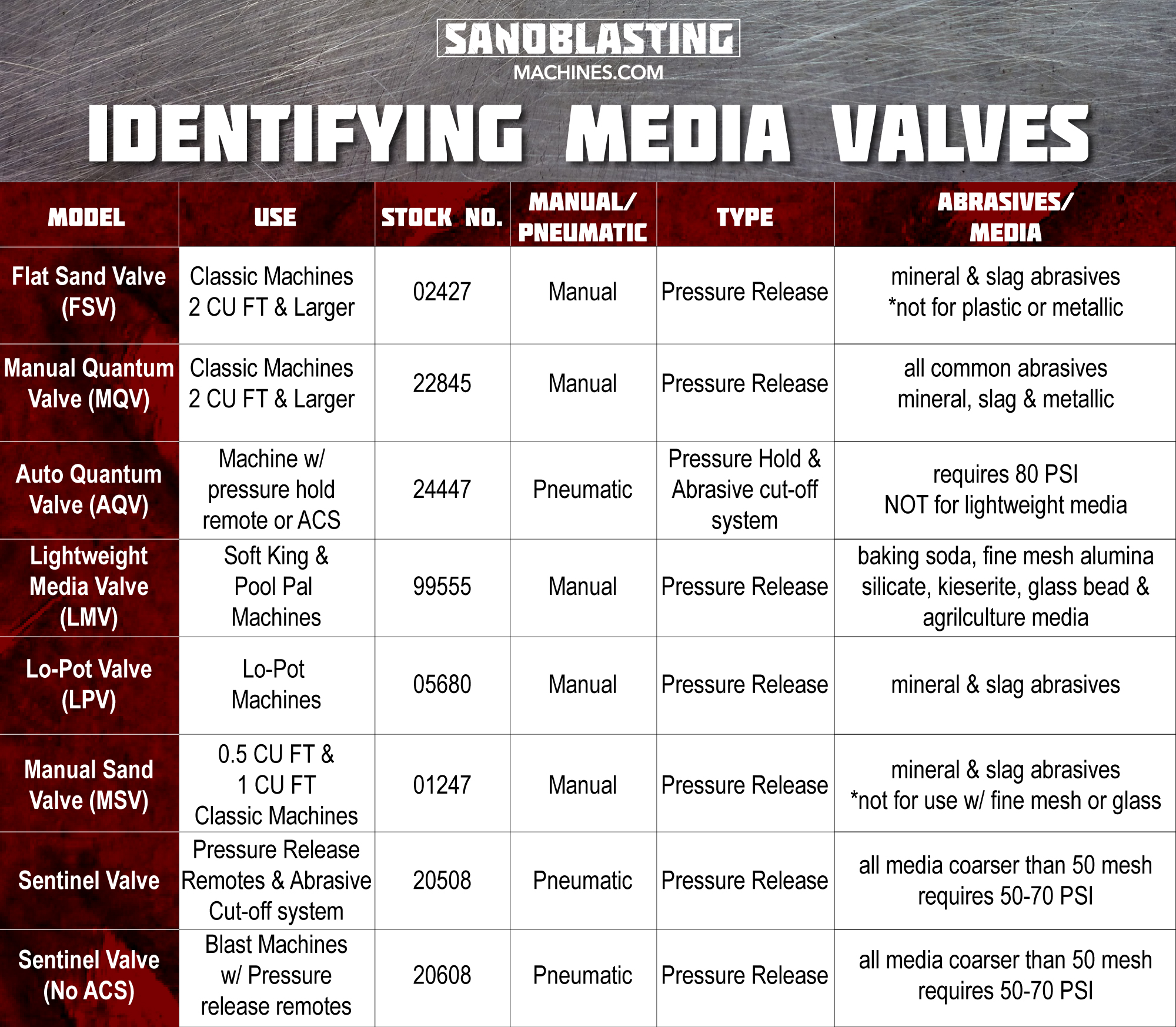

Types of Media Valves for Sandblasting Sandblasting Machines

Web The Below Charts Show A Few Types Of Abrasive Used In Dry Media Blasting.

When You Are Sandblasting Material, Make Sure It Is Done Correctly.

E Ach Abrasive Has A Listed Hardness Value, Surface Profile, Surface Removal Ability, And Velocity (If The Blasting Media Travels At A High Speed Or A Low Speed From The Blast Pot's Compressed Air).

Manual Valves Do Not Have A Shutoff To Stop The Flow Of Abrasive.

Related Post: