Size Of Welding Rod Chart

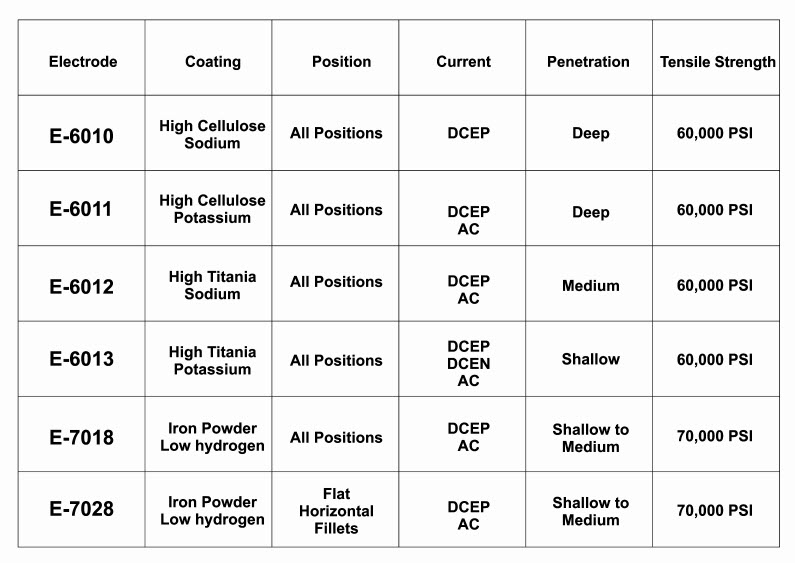

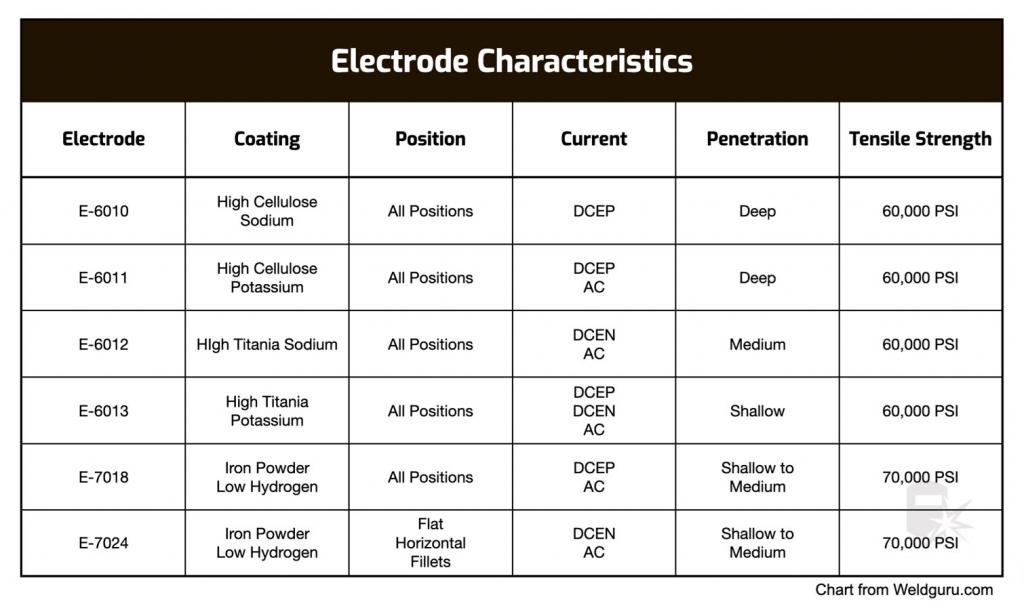

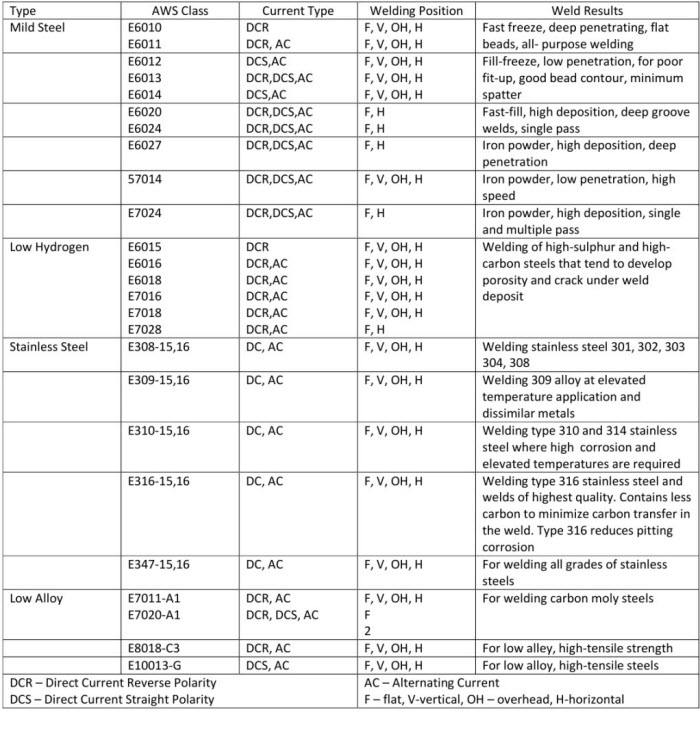

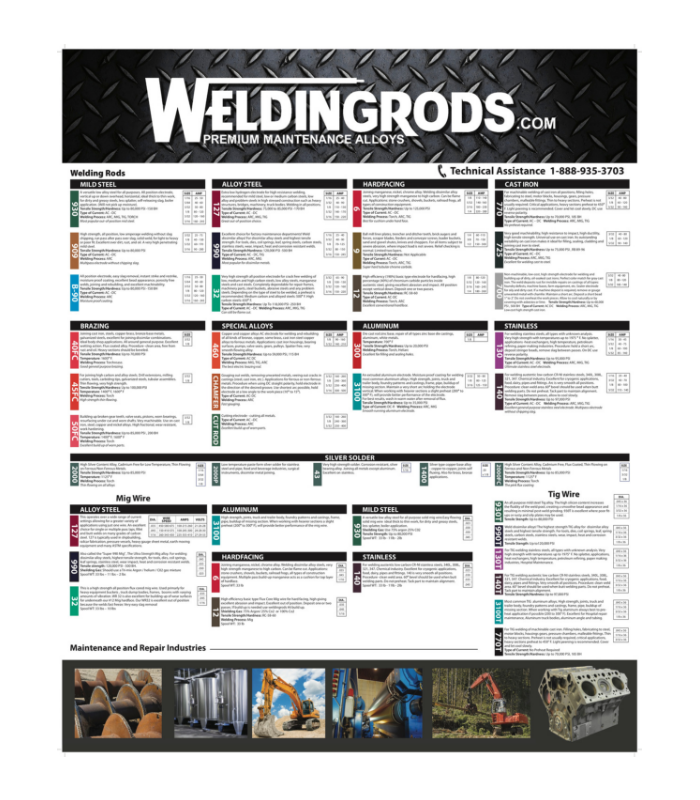

Size Of Welding Rod Chart - There are a variety of factors that go into choosing the right electrode for each project. 6010 and 6011 are virtually the same rod. The most popular welding rods for hobbyists are 3/32” rods. For example, e6012, e6013, e7014, and e7024. The smaller the welding rod, the higher the heat required to weld. Electrode amperage chart | types and thicknesses The tensile strength of a material refers to the maximum amount of tensile stress it can withstand before failing. Both welding electrodes have a violent digging arc, they are fast freeze, all position rods, the slag is thin and flaky and the penetration is deep. The most common diameter for general purpose welding is 3/32, 1/8 inch, and 5/32 inch. For example, e6010 and e6011. It is made out of materials with a similar composition to the metal being welded. For example, a 1/8″ e7024 is thicker than a 1/8″ e7014, and a 1/8″ e7018 is thicker than 1/8″ e6013. Almost all fusion welding processes require welding electrode to create the weld metal. The filler rods are also made with several alloys to handle different. Meanwhile, the smaller the rod is, it will be ideal for lower metal thickness and require less amperage. Web they are 6010, 6011, 6012, 6013, while the rest is 7014, 7018, and 7024. There are a variety of factors that go into choosing the right electrode for each project. 6010 and 6011 are virtually the same rod. 3/32″, 1/8″, and. Coating, welding positions, current, and tensile strength for each arc welding rod. Web different electrodes can have the same size but different overall thicknesses. The most important factor in choosing welding rod size is your welding material. Since the tig filler rod composition needed is often the same as that used for mig filler material, some of the mig wires. You might also find our welding calculators useful. Web different electrodes can have the same size but different overall thicknesses. Web they are 6010, 6011, 6012, 6013, while the rest is 7014, 7018, and 7024. Almost all fusion welding processes require welding electrode to create the weld metal. E6013 welding rod is a type of stick electrode. An electrode is a metal wire that is coated. The third number tells us it. Web what are common stick welding rod sizes. Web different electrodes can have the same size but different overall thicknesses. Electrodes for low alloy steel; Understanding tig welding filler rods. For example, e6012, e6013, e7014, and e7024. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. Almost all fusion welding processes require welding electrode to create the weld metal. Web the tensile strength is given in thousand pounds per square inch. The tensile strength of a material refers to the maximum amount of tensile stress it can withstand before failing. 3/32″, 1/8″, and 5/32″, as they are the most common rod sizes used in basic applications. Electrode amperage chart | types and thicknesses Web they are 6010, 6011, 6012, 6013, while the rest is 7014, 7018, and 7024. Each rod has. The chart above indicates the numerical relationship between amperes and welding rod sizes. For example, e6010 and e6011. The last digit signifies the type of coating used on the rod. We cover everything related to rod types, sizes, and how to pick the right one for your needs. Web a common size is.030 inches (7.62 mm), but other sizes are. Web home » welders » stick welders. A home welder often uses one of these sizes: Web in this guide, we’ll explore each aspect that goes into proper tig welding filler rod selection from material types and sizes to strength charts so you have everything you need to make an informed decision about what will work best for your project!. The most common diameter for general purpose welding is 3/32, 1/8 inch, and 5/32 inch. The pdf has 8 sections: 6010 and 6011 are virtually the same rod. The flux type that covers the rod: Web welding rod sizes explained. Web home » welders » stick welders. An electrode is a metal wire that is coated. The first two numbers, ’60’, say the tensile strength is 60,000 pounds per inch. Since the tig filler rod composition needed is often the same as that used for mig filler material, some of the mig wires are also sold for tig welding. Easy to use and suitable for thin metals. How to measure the diameter of a welding rod. It is made out of materials with a similar composition to the metal being welded. The tensile strength of a material refers to the maximum amount of tensile stress it can withstand before failing. For example, e6010 and e6011. Web the tensile strength is given in thousand pounds per square inch reading, so this electrode would contain 70,000 lb. Flat, horizontal, vertical (up or down), and overhead. Web a common size is.030 inches (7.62 mm), but other sizes are available, depending on the application. The last digit signifies the type of coating used on the rod. Web for example, if the part you’re working on calls for a 1/8″ (3.2 mm) fillet weld, but the material is 1/2″ (12.7 mm) thick, you would not want to use a 5/32″ (4 mm) electrode. Application for welding rod sizes. Meanwhile, the smaller the rod is, it will be ideal for lower metal thickness and require less amperage.

Search Result Details Welding rods, Welding tips, Welding videos

Arc Welding Rods Guide

What is Hardfacing Welding?

ER309L TIG Stainless Steel Welding Rod 36" All Sizes (Pack 1

Welding Rods Compared 6010, 6011, 6013, 7018 & 7024

Arc Welding Rods Guide

Welding Rod Chart

Welding Rod Chart

tigchart2 Welding rod chart, Welding rods, Welding and fabrication

Welding Rod List

Amperage Is The Strength Of The Direct Current Flowing Through The Rod During The.

Web What Are Common Stick Welding Rod Sizes.

The Flux Type That Covers The Rod:

Different Welding Rods Sizes, Types, And Their Uses.

Related Post: