Stainless Steel Welding Rod Chart

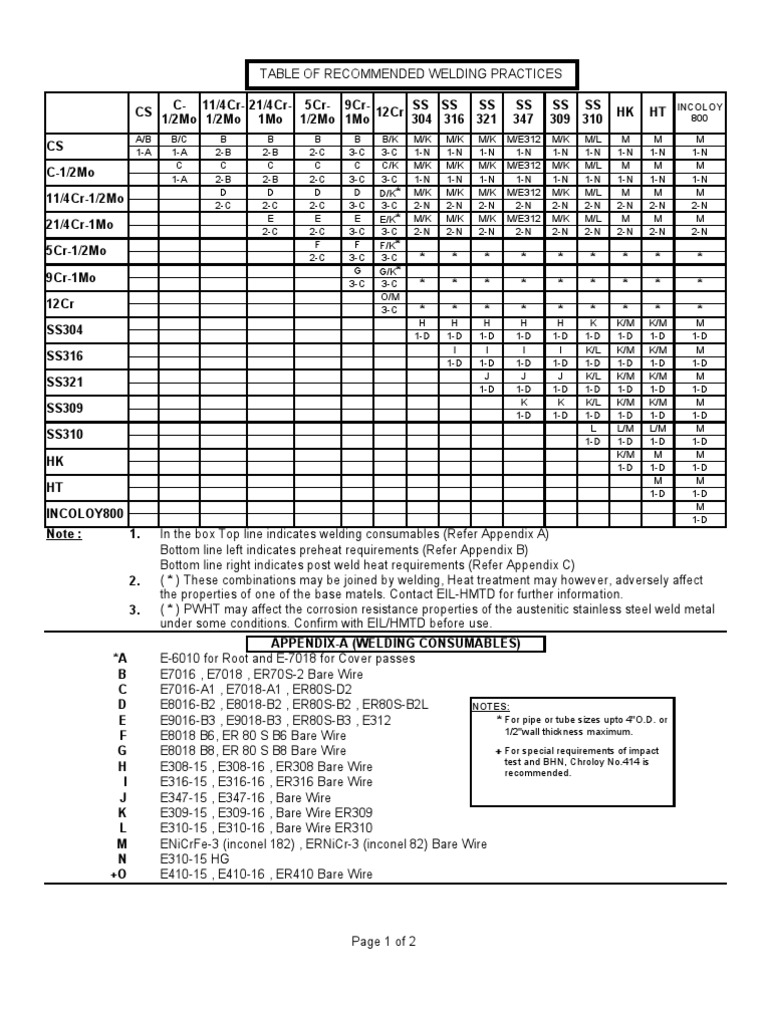

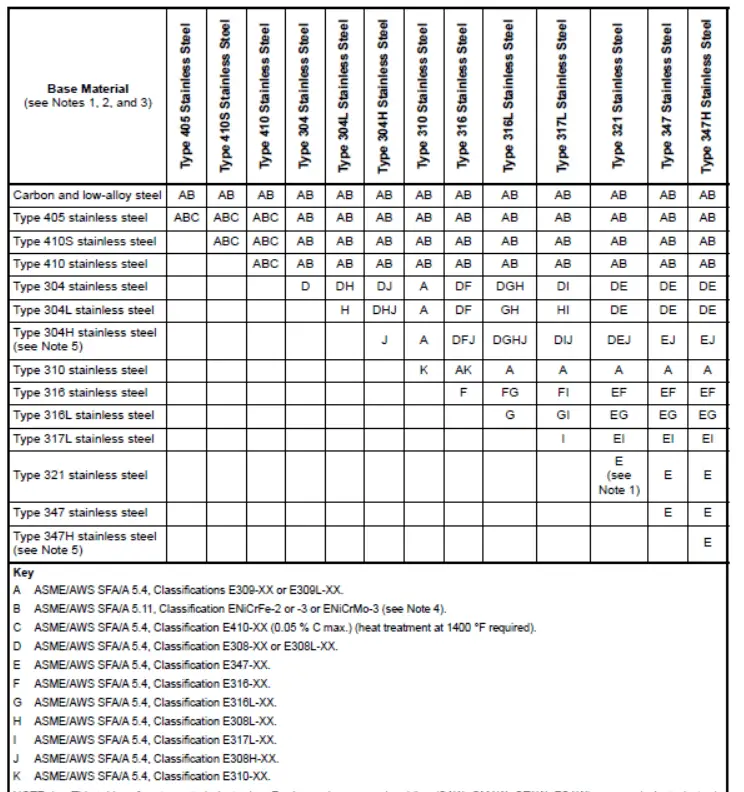

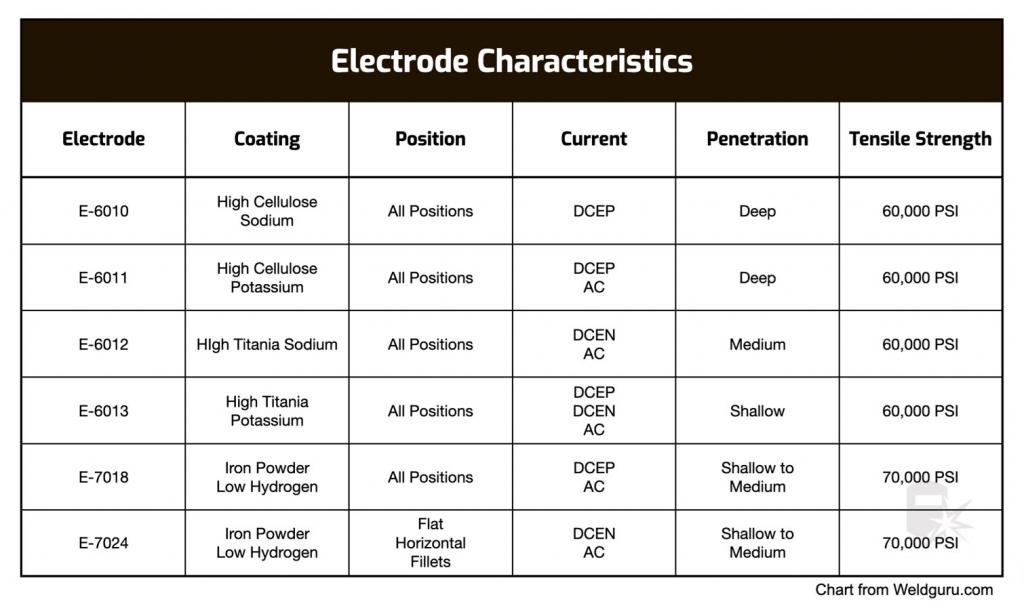

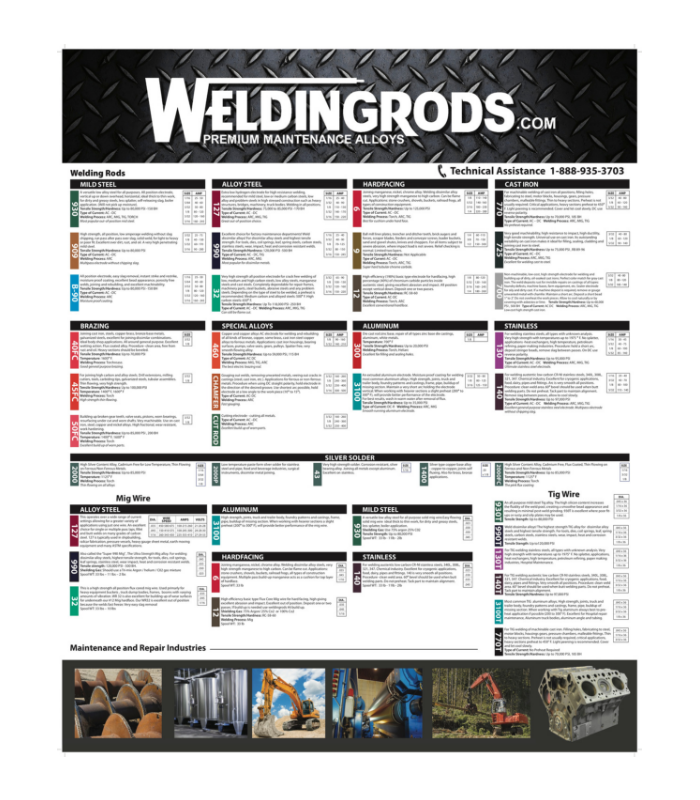

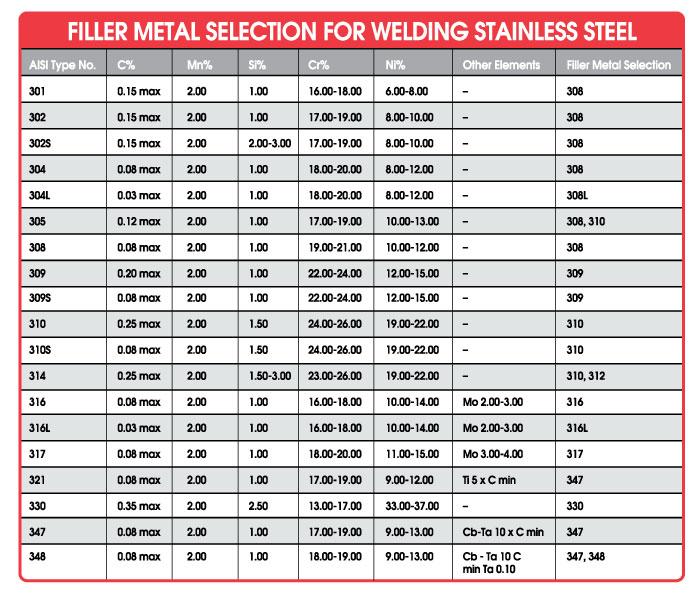

Stainless Steel Welding Rod Chart - The pdf has 8 sections: Each of these electrodes is available in different rod sizes. Web among the most common types of tig welding rods are er308l, er309l, er310, er316l, er321 and er347. Web stainless filler metal selector guide aisi type number 442 446 430f 430 fse 430 431 501 502 416 416 se 403 405 410 420 414 321 348 347 317 316l 316 314 310 310s 309 309s Web e7024 size and amperage chart; Most commercial grades are higher than 11 percent chromium and contain up to about 0.08 percent carbon. Web it is typically used to make welding electrodes and used to join common types of austenitic stainless steels, such as 301, 302, 304 and 305. Er308l is primarily used for welding austenitic stainless steels such as 304 and 304l. Web the two leading austenitic stainless steel filler metal contenders for dissimilar metal welding are 309 (l) and 312. These are identified as “tig cut lengths.” choosing a filler rod. Flux composition & current chart; Faqs about welding stainless steel. Web there are many methods of welding stainless steel, including mig, gtaw, tig, and stick welding. Web home » welders » stick welders. An electrode is a metal wire that is coated. Stainless steels are defined as iron base alloys containing relatively low carbon and a minimum of about 11 percent chromium (some put the minimum at 10 percent and others at 12 percent). Web e7024 size and amperage chart; This specification prescribes the requirements for classification of bare stainless steel electrodes (both as wire and strip) for gas metal arc welding,. Can you weld stainless steel? The size of the tig welding rod, also known as the filler metal, is determined by the thickness of the material being welded and the desired strength of. The selection should be based on the material of the stainless steel and working conditions such as operating temperature, contact medium, etc. Additionally, we will give you. There are a variety of factors that go into choosing the right electrode for. Web there are many methods of welding stainless steel, including mig, gtaw, tig, and stick welding. Web you’re likely to come across these electrodes the most: The “magic” companies that do an excellent job in maintenance and repair welding all favor a version of type 312. Flux composition & current chart; Web home » welders » stick welders. Also, a great deal of information on weld rod selection is available from the american welding society (aws), weld rod manufacturers, and stainless steel producers. Web additional information on weld rod selection is provided in the next section on welding processes used for stainless steels. There are advantages. The size of the tig welding rod, also known as the filler metal, is determined by the thickness of the material being welded and the desired strength of. Most commercial grades are higher than 11 percent chromium and contain up to about 0.08 percent carbon. There are a variety of factors that go into choosing the right electrode for. Different. E308l stainless steel welding rod chart; The filler rods are also made with several alloys to handle different metals. (siws) is not sponsored, affiliated or in any way related to stoody company, a division of thermadyne. Web additional information on weld rod selection is provided in the next section on welding processes used for stainless steels. Web there are many. Stainless steels are defined as iron base alloys containing relatively low carbon and a minimum of about 11 percent chromium (some put the minimum at 10 percent and others at 12 percent). Since the tig filler rod composition needed is often the same as that used for mig filler material, some of the mig wires are also sold for tig. Web there are many methods of welding stainless steel, including mig, gtaw, tig, and stick welding. Er308l is primarily used for welding austenitic stainless steels such as 304 and 304l. An electrode is a metal wire that is coated. Stainless steels are defined as iron base alloys containing relatively low carbon and a minimum of about 11 percent chromium (some. Also, a great deal of information on weld rod selection is available from the american welding society (aws), weld rod manufacturers, and stainless steel producers. Additionally, we will give you tig filler rod charts for all standard and less often used rods, including titanium. These are common welding rods used in shielded metal arc welding or stick welding. Web you’re. Web this article will teach you the basics of tig filler rods and help you establish your filler rod collection because 99% of the jobs are done with the rods we will discuss soon. Er309l suitable for joining dissimilar metals such as mild steel to stainless steel. We cover everything related to rod types, sizes, and how to pick the right one for your needs. E6010, e6011, e6013, and e7018. The filler rods are also made with several alloys to handle different metals. Electrodes for low alloy steel; Can you weld stainless steel? Web e7024 size and amperage chart; Additionally, we will give you tig filler rod charts for all standard and less often used rods, including titanium. Web home » welders » stick welders. Er308l is primarily used for welding austenitic stainless steels such as 304 and 304l. (siws) is not sponsored, affiliated or in any way related to stoody company, a division of thermadyne. This specification prescribes the requirements for classification of bare stainless steel electrodes (both as wire and strip) for gas metal arc welding, submerged arc welding, and other fusion welding processes. Web stainless filler metal selector guide aisi type number 442 446 430f 430 fse 430 431 501 502 416 416 se 403 405 410 420 414 321 348 347 317 316l 316 314 310 310s 309 309s Web in this welding rod chart, you will find over 220 stick electrodes classified according to the american welding society (aws) code. Each of these electrodes is available in different rod sizes.

Search Result Details Welding rods, Welding tips, Welding videos

Aluminum Filler Metal Chart

400 Mm Stainless Steel SS Welding Rods, Size 2.5 mm, Rs 2000 /box ID

Welding Rods Compared 6010, 6011, 6013, 7018 & 7024

WELDING CHART Stainless Steel Pipe (Fluid Conveyance)

Welding Rod Stainless Nihonweld NSS308 5/64" 2.0 mm *SOLD PER KILO

tigchart2 Welding rod chart, Welding rods, Welding and fabrication

Welding Rod Chart

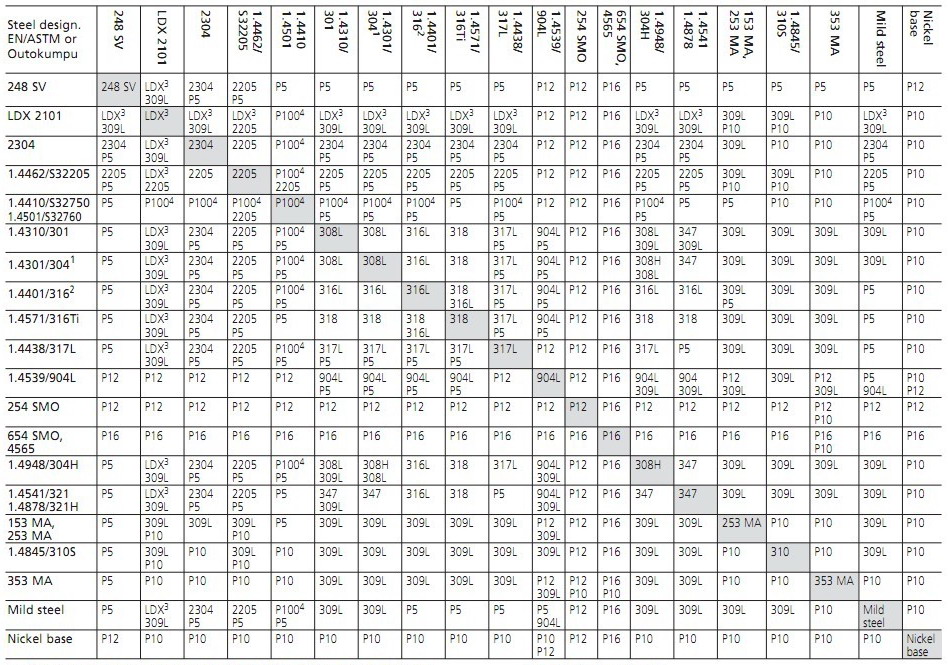

Filler Metals For Welding Stainless Steel LDX2101 S32205 2304 254SMO

Welding austenitic stainless steel

Since The Tig Filler Rod Composition Needed Is Often The Same As That Used For Mig Filler Material, Some Of The Mig Wires Are Also Sold For Tig Welding.

The Pdf Has 8 Sections:

Web The Two Leading Austenitic Stainless Steel Filler Metal Contenders For Dissimilar Metal Welding Are 309 (L) And 312.

The “Magic” Companies That Do An Excellent Job In Maintenance And Repair Welding All Favor A Version Of Type 312 For Most Applications.

Related Post: