Stick Weld Amperage Chart

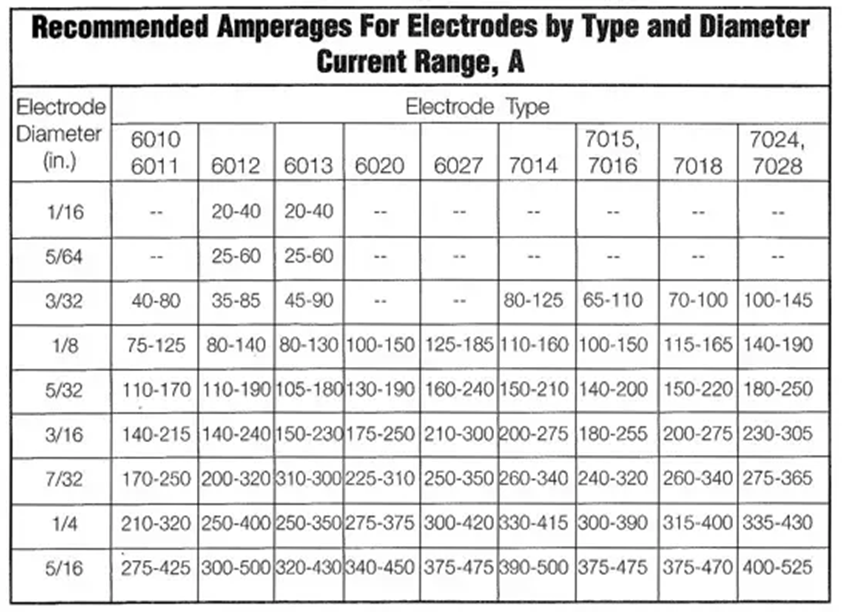

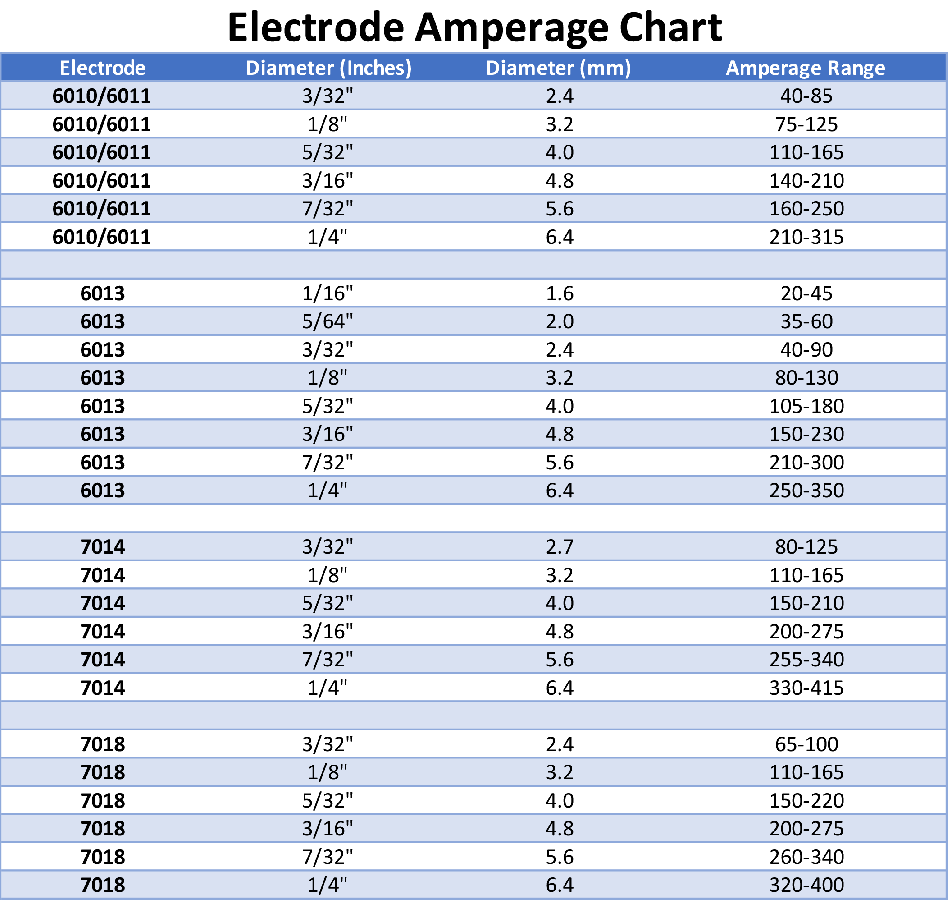

Stick Weld Amperage Chart - For example, 3/32” rod diameter would be (.094) 90 amps, 1/8” rod. The table is published in aws a5.1 specification. Use less amps on thin metal; This stick welding amperage chart provided recommended welding amperage for different rod diameters. The pdf has 8 sections: Vertical stick welding amperage per metal thickness in inches and mm. Making adjustments on stick welders. Web in this welding rod chart, you will find over 220 stick electrodes classified according to the american welding society (aws) code. Web in the stick welding amperage chart below, we have examples of each coating associated with the last two digits found on each electrode used in stick welding. What are the common sizes of tig welding rods? Web the amperage chart is a valuable tool to assist in setting the correct amperage range for stick welding. A good rule of thumb for setting your stick welder (smaw) to the approximate right setting to start off with is the amperage setting should be about the same as the decimal equivalent of the rod diameter. Web include diese welding. This help determines what the various options are designed for and which ones should be used at different times. Electrodes for low alloy steel. What are the common sizes of tig welding rods? Web the amperage chart is a valuable tool to assist in setting the correct amperage range for stick welding. For example, e6012, e6013, e7014, and e7024. Can you stick weld vertically? Is it easier to stick weld up or down? Dc, electrode positive (reverse polarity) has the most weld penetration. This stick welding amperage chart provided recommended welding amperage for different rod diameters. Electrodes to low alloy steel. Find the amperage for a type and thickness of metal on a welding chart. Web miller® stick welding calculator provides quick reference for stick welding parameters, including: Web the amperage chart is a valuable tool to assist in setting the correct amperage range for stick welding. Remember, thicker material and larger electrodes require higher amperage. Diameter (inches) diameter (mm) 6010/6011. The table is published in aws a5.1 specification. Web you can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding. What material are you welding? Arc force (dig) for vertical welding. An electric current passes through the electrode and melts it. Arc force (dig) for vertical welding. For example, e6010 and e6011. As a general rule, e7018 stick electrodes are a good choice for structural steel applications due to their smooth, stable and quiet arc, and their low spatter levels. There are many types of welding rods in different sizes, and as a welder, it’s kinda difficult to memorize everything. Look. Dc, electrode positive (reverse polarity) has the most weld penetration. Web include diese welding rod chart, you will find over 220 sticking electrodes classified according to the american welding society (aws) code. Electrodes for copper and copper alloys. Arc force (dig) for vertical welding. Can you stick weld vertically? Metal thickness/amperage, electrode/welding position, current type/polarity, basic techniques and process information for stick (smaw) welding. Can you stick weld vertically? Should you stick weld up or down? Electrical for copper and copper alloys. Web table of contents. Use less amps on thin metal; Web the amperage chart is a valuable tool to assist in setting the correct amperage range for stick welding. Easy to use and suitable for thin metals. What material are you welding? There are many types of welding rods in different sizes, and as a welder, it’s kinda difficult to memorize everything. Look for a stick welding amperage chart online or in your stick welder’s manufacturer’s instructions. Web amperage settings chart for stick welding. Electrodes for copper and copper alloys. Web stick welding amperage chart of electrode type vs diameter pro tip: For example, e7016, e7018, and e7028. Easy to use and suitable for thin metals. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. Arc force (dig) for vertical welding. Web you can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding. Electrodes for copper and copper alloys. Electrodes for low alloy steel. Should you stick weld up or down? Is it easier to stick weld up or down? As a general rule, e7018 stick electrodes are a good choice for structural steel applications due to their smooth, stable and quiet arc, and their low spatter levels. Web table of contents. Web contents [ show] what is stick welding (smaw)? Electrodes to low alloy steel. More amps on thick metal. Download the app version of the weld setting calculator for easy reference! Metal thickness/amperage, electrode/welding position, current type/polarity, basic techniques and process information for stick (smaw) welding. Web welding rod sizes explained.

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

Stick Welding (SMAW) Amperage Chart For All Types of Work Simpleweld

Tig Weld Amp Chart

ضبط الامبير للحام القواعد الذهبية فى اللحام القاعدة الرابعةWelding

electrodeamperagechart.gif gif by ac712s Photobucket

Avoiding arc start porosity on 7018? Page 2

7018 welding rod amp chart Fomo

![Best Amperage Settings for Stick Welding [Download Chart] Let's Weld](https://www.iamwelder.com/wp-content/uploads/2022/12/best-amperage-setting-for-stick-welding-1000x600.webp)

Best Amperage Settings for Stick Welding [Download Chart] Let's Weld

How to Prevent Welding Rod Sticking to The Metal Welding Tribe

Stick Welding (SMAW) Amperage Chart For All Types of Work Simpleweld

An Electric Current Passes Through The Electrode And Melts It.

Vertical Stick Welding Amperage Per Metal Thickness In Inches And Mm.

Web Choose The Right Amperage For Stick Welding By Considering Material Thickness And Electrode Diameter.

Look For A Stick Welding Amperage Chart Online Or In Your Stick Welder’s Manufacturer’s Instructions.

Related Post: