Tig Amp Chart

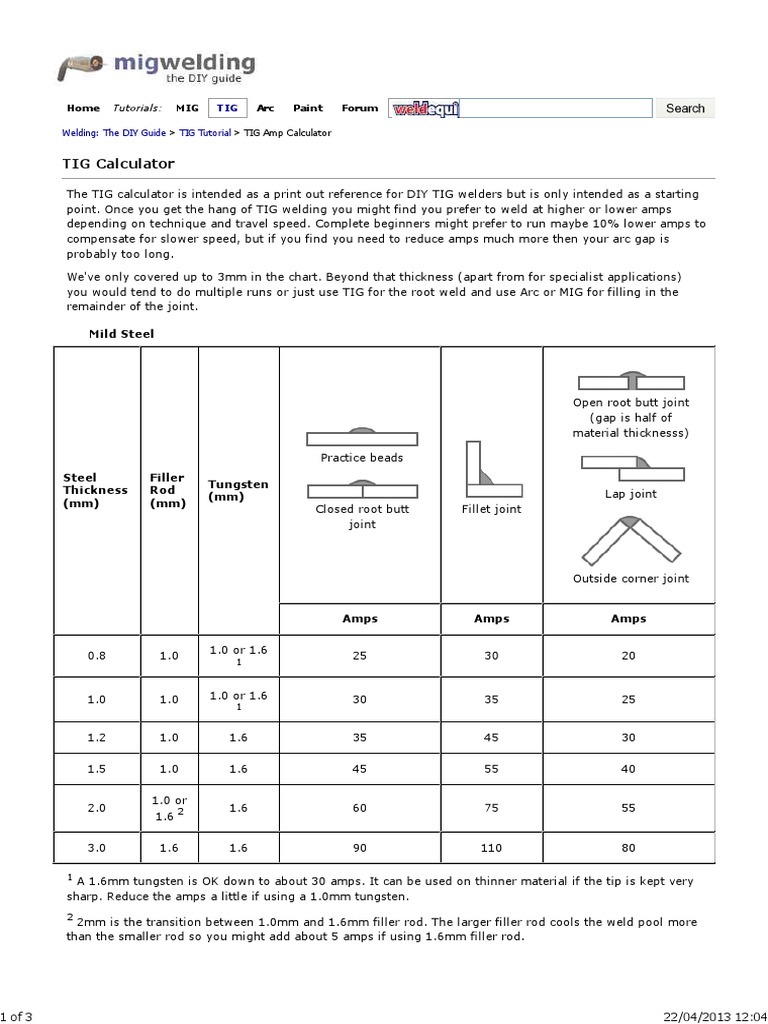

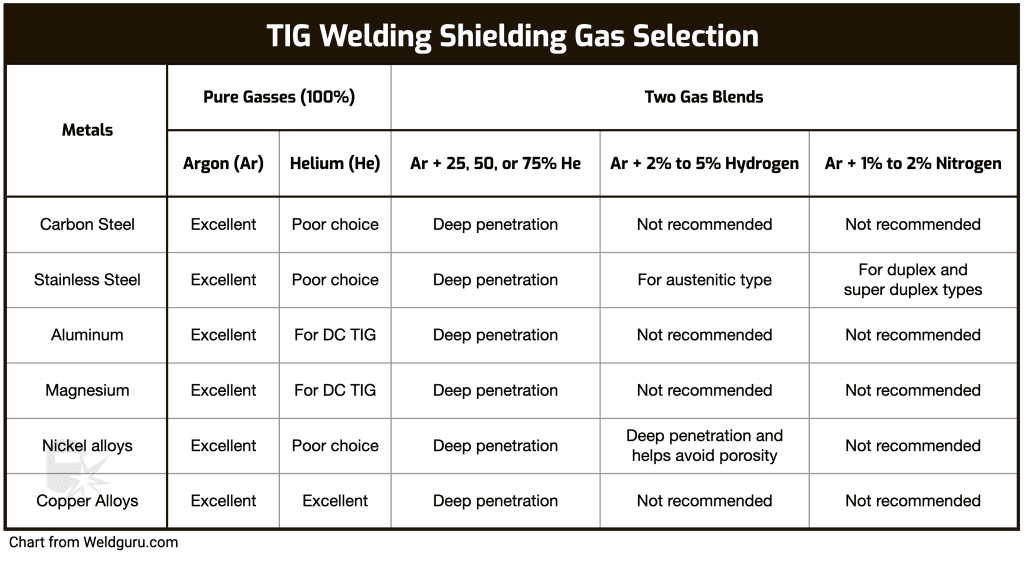

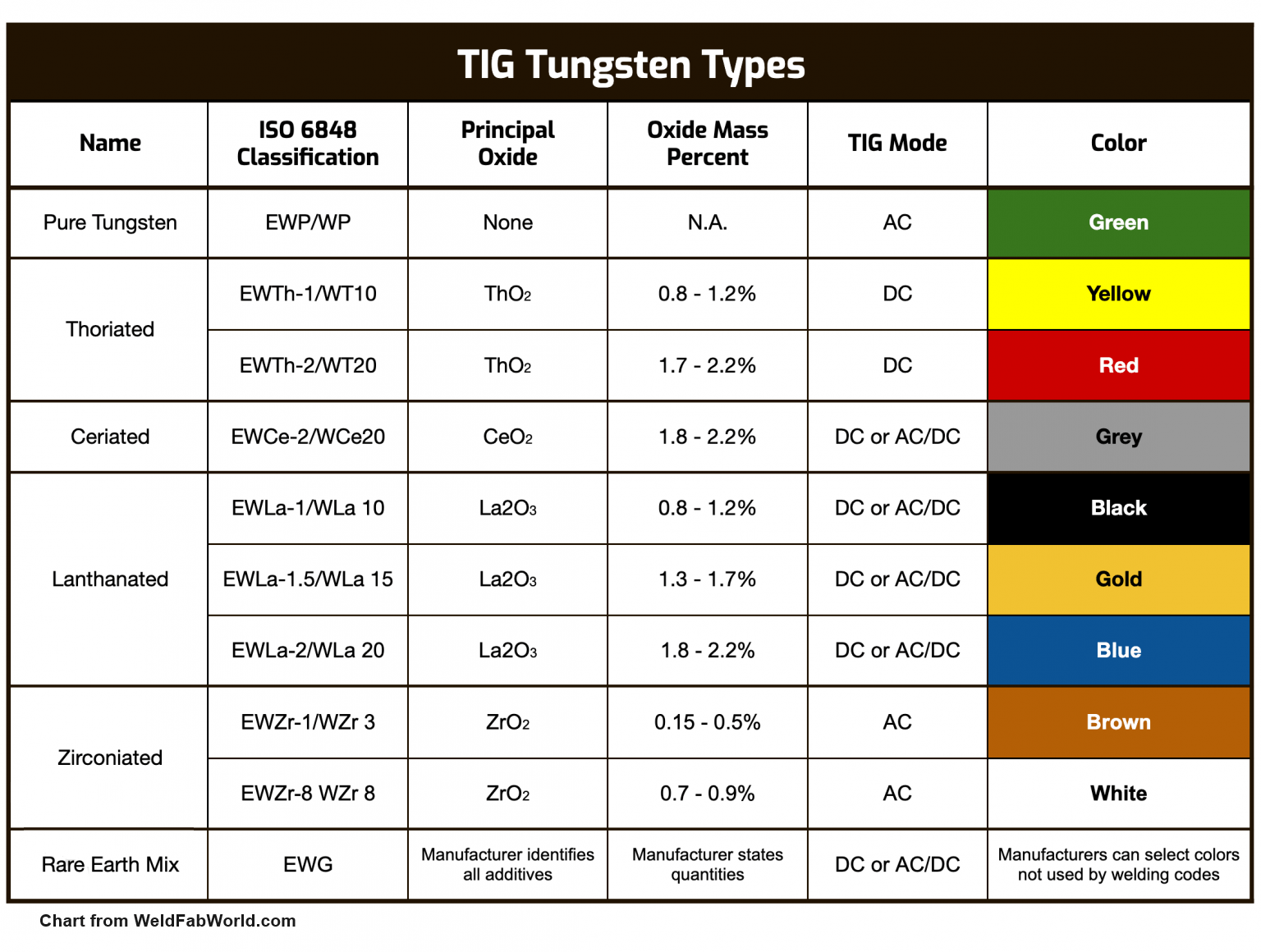

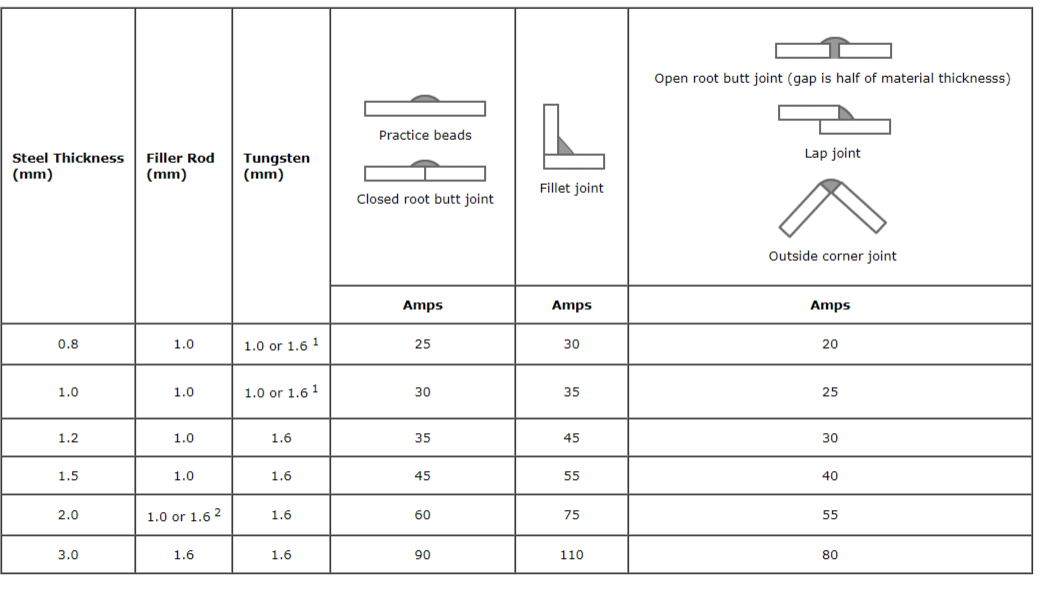

Tig Amp Chart - Web welders are often looking for a good reference detailing recommended amperage levels based on tungsten welding electrode size and type. 9.1 steps for tig welds on aluminum. See the chart below for current ranges of all sizes. A little less than one amp for stainless. 8.2 is helium a good option. Download the app version of the weld setting calculator for easy. Thicker materials will require more current and thus bigger tungsten. It caters to different material types and thicknesses for effective welding. By inputting data like material thickness and type, the calculator offers specific recommendations for amperage, voltage, and gas flow rate. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. Web welders are often looking for a good reference detailing recommended amperage levels based on tungsten welding electrode size and type. 9.1.1 cleaning contaminants and oils on the surface. Metal thickness/amperage, electrode/wire type, shielding gas type/flow rate, basic techniques and process information for tig (gtaw) welding. What metal are you welding? Web tig welding chart based on material and shielding. For the best appearance, highest quality and leak free welds on aluminum, ac tig welding is the process of choice. The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Printable charts shiowing the amps and tungstons you might select. Whether you’re new to pulsed tig welding or trying to get the stacked dimes look, selecting the right settings is the key to success. The three main types of metals typically worked on with a. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. It caters to different material types and thicknesses for effective welding. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web • amperage —pretty straightforward.but there is a simple rule of thumb that holds true up to. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Metal thickness/amperage, electrode/wire type, shielding gas type/flow rate, basic techniques and process information for tig (gtaw) welding. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. How to determine tig welding. For beginners it’s recommended to stick. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. What metal are you welding? There are a variety of torches within the different weldcraft series. Web miller® tig welding calculator provides quick reference for tig welding parameters, including: / understanding tig pulse settings with ron covell. Web tig welding chart based on material and shielding gas. Web • amperage —pretty straightforward.but there is a simple rule of thumb that holds true up to about.125 thick metal. For mild steel, it recommends running 10% lower amps for complete beginners. Additionally, you might have your own preference. Web mainly on the material thickness and the amperage needed to. Although midwest tungsten service only provides 1/16, 3/32, and 1/8 electrodes, some projects call for a slightly bigger diameter, such as 5/32 or 3/16. Whether you’re new to pulsed tig welding or trying to get the stacked dimes look, selecting the right settings is the key to success. See the chart below for current ranges of all sizes. Working of. Ac tig is generally used to weld aluminum and magnesium materials. Printable charts shiowing the amps and tungstons you might select. A little less than one amp for stainless. Web • amperage —pretty straightforward.but there is a simple rule of thumb that holds true up to about.125 thick metal. By inputting data like material thickness and type, the calculator offers. 8.2 is helium a good option. For mild steel, it recommends running 10% lower amps for complete beginners. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Metal thickness/amperage, electrode/wire type, shielding gas type/flow rate, basic techniques and process information for tig (gtaw) welding. An. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web what is an aluminum tig welding settings chart? For mild steel, it recommends running 10% lower amps for complete beginners. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. 8.4 is carbon dioxide on aluminum any good. For the best appearance, highest quality and leak free welds on aluminum, ac tig welding is the process of choice. Meanwhile, tig welding calculators help welders determine the right settings for their welding machine based on specific variables such as the type of material being welded, the thickness of the material, and the desired weld size. How to determine tig welding. Ac tig is generally used to weld aluminum and magnesium materials. Although midwest tungsten service only provides 1/16, 3/32, and 1/8 electrodes, some projects call for a slightly bigger diameter, such as 5/32 or 3/16. Whether you’re new to pulsed tig welding or trying to get the stacked dimes look, selecting the right settings is the key to success. It helps welders set the correct parameters for welding aluminum. A filler rod is often fed into the weld pool by the operator to create a weld. See the chart below for current ranges of all sizes. These include amperage, gas flows, and filler rod sizes. Web 8 what gas should you use.TIG Welding Amp Charts Welding Building Materials

Tig parameters chart MIG Welding Forum

Tig Shielding Gas Chart

Imagen de Nora Thompson de DC para recortar Loca Tel

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

welding table frame Weldingtable Welding, Welding table, Tig welding

Tungsten Electrodes For TIG (with Color Chart) Welding Fabrication World

TIG

![Tungsten Electrode Journey to the Center of TIG Welding [2020]](https://vietmfg.com/wp-content/uploads/2020/08/tig-welding-current-ranges-for-tungsten-electrodes.png)

Tungsten Electrode Journey to the Center of TIG Welding [2020]

TIG Tungsten Electrodes Explained (with Color Chart), 59 OFF

9.1.1 Cleaning Contaminants And Oils On The Surface.

Web Mainly On The Material Thickness And The Amperage Needed To Achieve A Proper Weld.

Web Miller® Tig Welding Calculator Provides Quick Reference For Tig Welding Parameters, Including:

By Inputting Data Like Material Thickness And Type, The Calculator Offers Specific Recommendations For Amperage, Voltage, And Gas Flow Rate.

Related Post: