Tire Nut Torque Chart

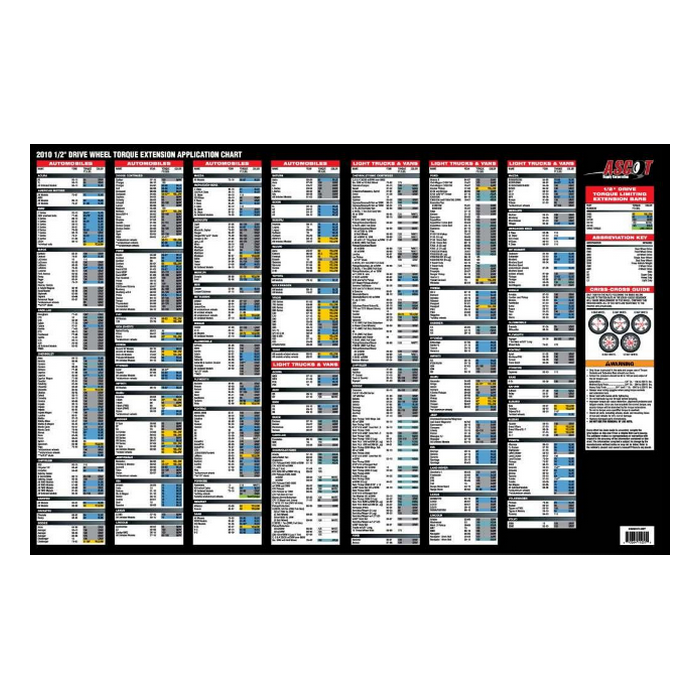

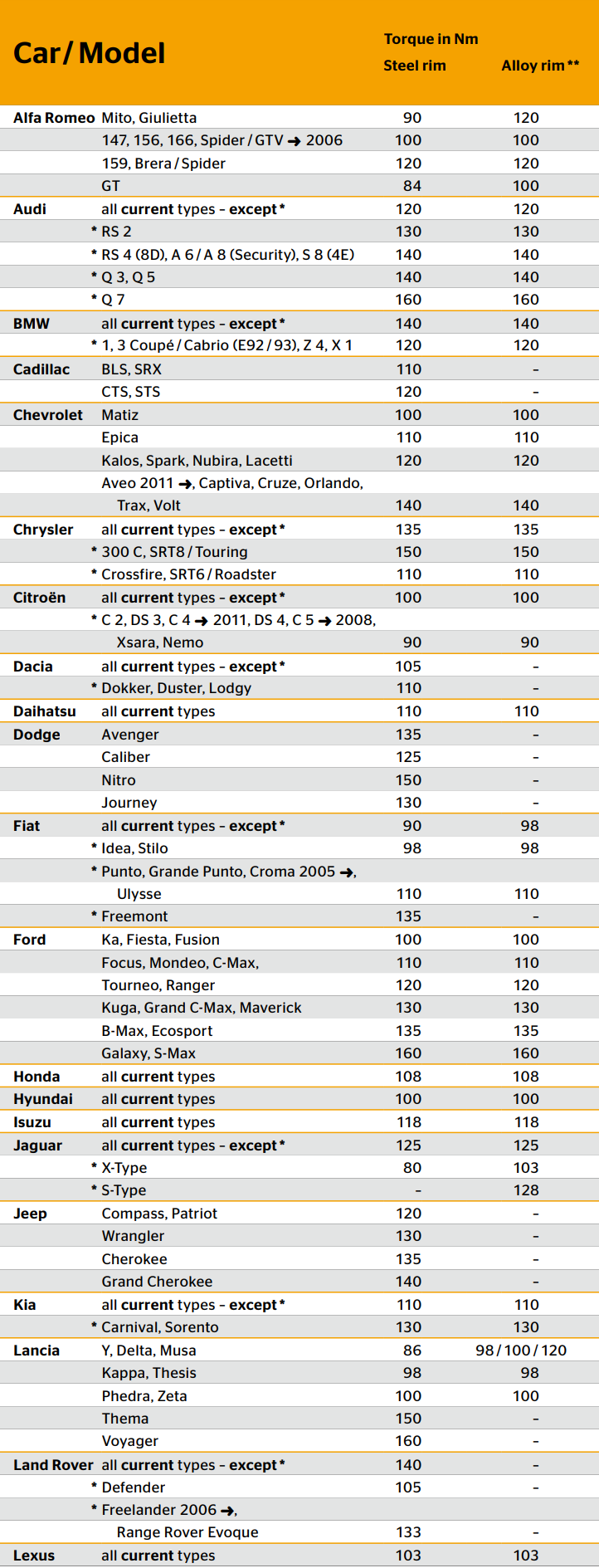

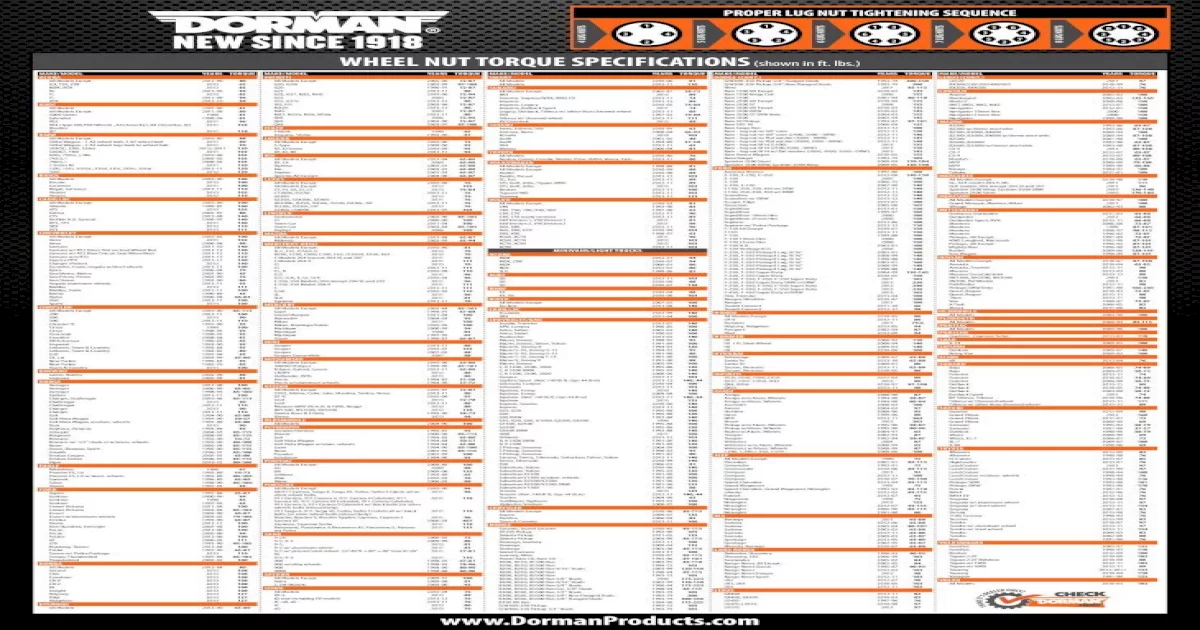

Tire Nut Torque Chart - Due to the many different size studs used in the 1st generation to 5th generation f150, these will be omitted from the above chart. Need more help with your wheels? Web result how tight should lug nuts be? The general rule for steel wheel lug nut torque is usually around 80ft/lb, and for aluminum wheels it is around 100ft/lb, this being said you still need to check on the manufacturer's specifications. Web result you can refer to your owner's manual, reach out to your ford dealership, or use the below ford f150 lug nut torque spec chart for the correct torque value. The key to torquing your wheels is to avoid using an impact wrench or any other tool that does not give you a gauge to measure the amount to the tightness of the lug nuts. Check out the wheel torque chart. Wall chart provides proper lug nut torque specifications for over 372 cars and light trucks. Web result once secured hand tight, use the torque wrench set to the proper torque as indicated from a lug nut torque chart or the vehicle’s owner's manual, for the final tightening sequence based on the number of studs or bolts as shown below. Torque specifications are found in your owner’s manual, and they refer to dry threads only. Due to the many different size studs used in the 1st generation to 5th generation f150, these will be omitted from the above chart. Drive safe and secure, get your wheels checked. 2 applying the correct torque. 2.1 the importance of torque wrenches. Web result www.dormanproducts.com wheel nut torque specifications. Click here to purchase the 2022. Web result how tight should lug nuts be? Lbs.) infiniti all models except: Can i drive with 2 lug nuts? Web result 1.1 types and sizes of lug nuts. Year range 1990 to 2022. 2.2 adhering to torque patterns and specifications. For 372+ cars and light trucks. Web result how tight should the lug nuts be on my vehicle? The key to torquing your wheels is to avoid using an impact wrench or any other tool that does not give you a gauge to measure the amount to the. Durable, folded, coated chart for longer wear. Use a wire brush to remove dirt and rust. Web result a lug nut torque spec chart provides the proper torque specifications for your car’s wheels. This chart has the most up to date torque specification for use with original equipment wheels. The key to torquing your wheels is to avoid using an. Read on to learn more about the lug nut torque, its specs, and how to read its spec chart. Do it once and do it right. Web result www.dormanproducts.com wheel nut torque specifications. It serves as a guide to making sure you apply the right amount of force when installing the lug nuts. Lbs.) make/model years torque acura. Faces of hub and wheels for dirt, rust or damage. Safety and performance depend on torque. Need more help with your wheels? Web result 1.1 types and sizes of lug nuts. For 372+ cars and light trucks. Be sure to follow the torque sequence shown above for your specific lug count. These torque specifications can also be found in your vehicle's shop manual or obtained from your vehicle dealer. Proper wheel torque sequence is critical for installation and to ensure safety on the road. Do it once and do it right. It serves as a guide to. 2 applying the correct torque. This means no dirt, corrosion or oil should be present, including lubrication. Putting the proper torque on the center axle nut sets the preload for the bearing and keeps the bearing from separating while in operation. Lug nut torque [specs and spec chart] Web result how tight should the lug nuts be on my vehicle? This means no dirt, corrosion or oil should be present, including lubrication. Find a store near you These torque specifications can also be found in your vehicle's shop manual or obtained from your vehicle dealer. The key to torquing your wheels is to avoid using an impact wrench or any other tool that does not give you a gauge to. Web result lug nut torque guide name model years torque (ft. 1.2 proper installation and torque specifications. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a speciic torque value. Use a wire brush to remove dirt and rust. The general rule for steel wheel lug nut torque is. Web result how tight should the lug nuts be on my vehicle? Web result tightening the lug nuts and bolts correctly also reduces the chance of warping the brake drums, rotors or hubs. Be sure to follow the torque sequence shown above for your specific lug count. 1.2 proper installation and torque specifications. When wanting to torque your wheels correctly, you need to use a torque wrench. Web result how tight should lug nuts be? Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a speciic torque value. It serves as a guide to making sure you apply the right amount of force when installing the lug nuts. Faces of hub and wheels for dirt, rust or damage. Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. Click here to purchase the 2022. Year range 1990 to 2022. Web result 1.1 types and sizes of lug nuts. Before you use the torque sticks, check all parts, including wheels, studs and mounting. Lbs.) infiniti all models except: Read on to learn more about the lug nut torque, its specs, and how to read its spec chart.

K Tool International KTI30103A Ktool 2019 Torque Chart, Wheel Nut Torq

2016 Dodge Challenger Lug Nut Torque Spec

Torque Products Tire Supply Network

Wheel Torque Chart Settings

How To Find Out Torque Specifications for Screws and Bolts An

Wheel Nut Torque Chart Australia lupon.gov.ph

Tire Inflation Pressure, Wheel Torque & Sizes (GT/GTS) Celica Hobby

Printable Automotive Wheel Torque Chart Printable World Holiday

Printable Lug Nut Torque Chart Printable Blank World

2014 Ford Focus Lug Nut Torque

The General Rule For Steel Wheel Lug Nut Torque Is Usually Around 80Ft/Lb, And For Aluminum Wheels It Is Around 100Ft/Lb, This Being Said You Still Need To Check On The Manufacturer's Specifications.

Safety And Performance Depend On Torque.

For 372+ Cars And Light Trucks.

Web Result Torque The Lug Nuts In Two Steps, Starting At 40 Ft/Lbs Of Torque For Your First Step To Get The Wheel Seated Properly.

Related Post: