Torque Flange Chart

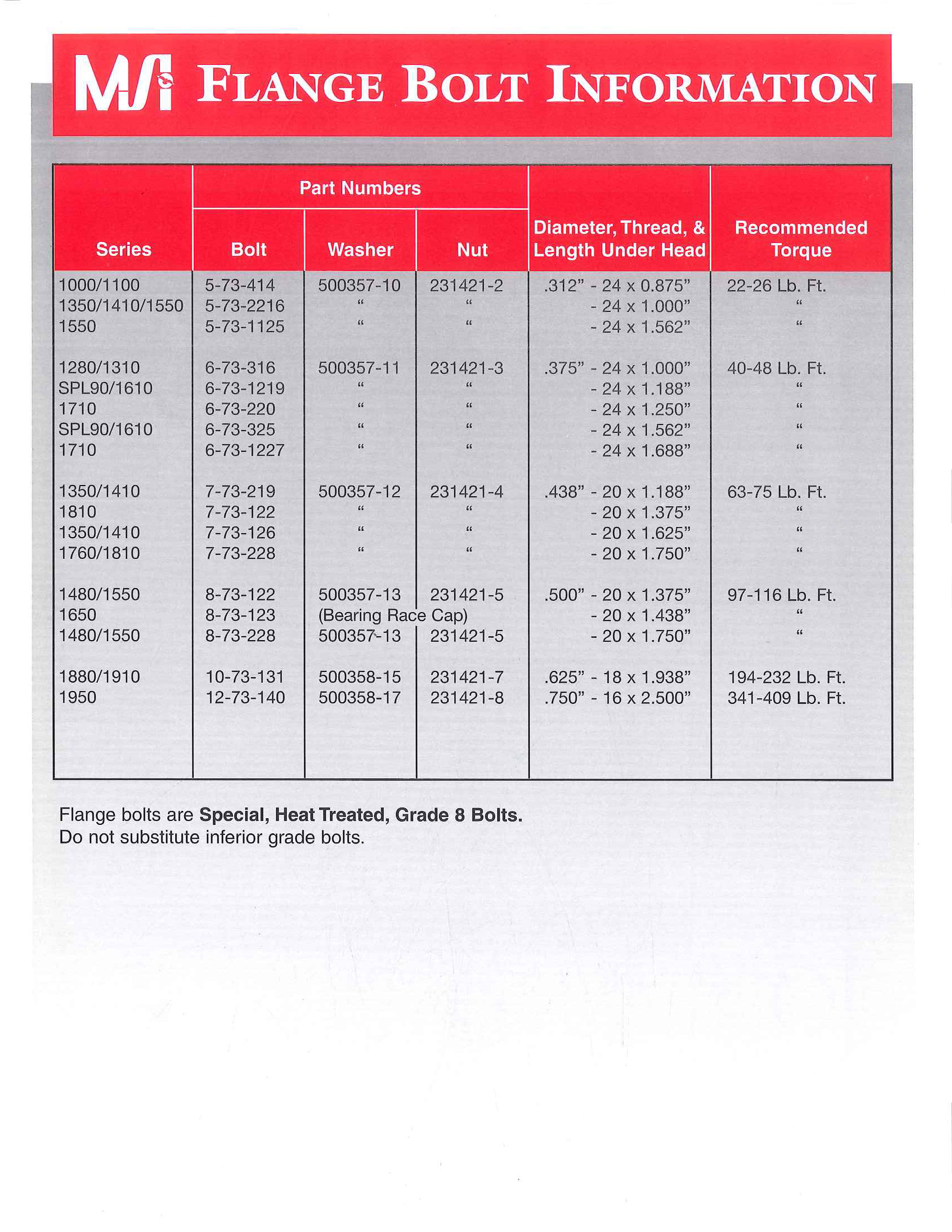

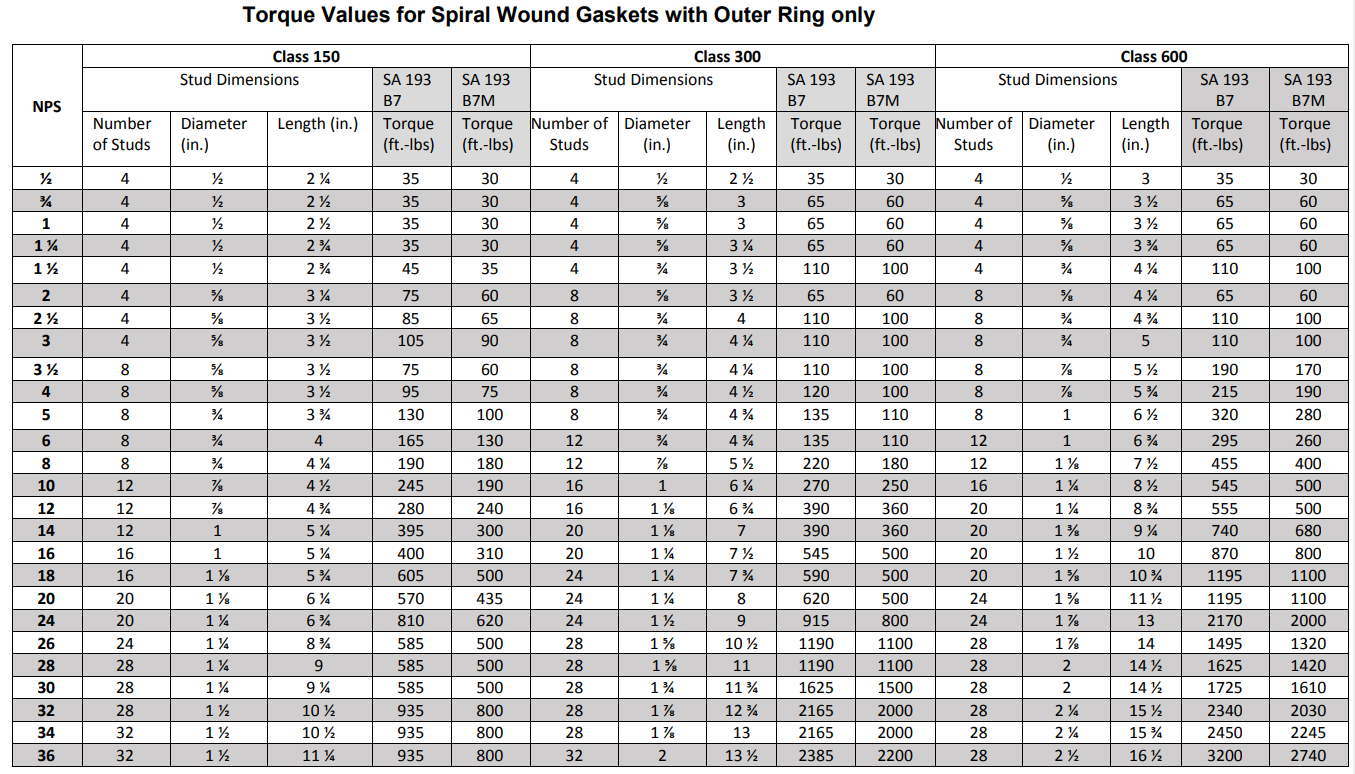

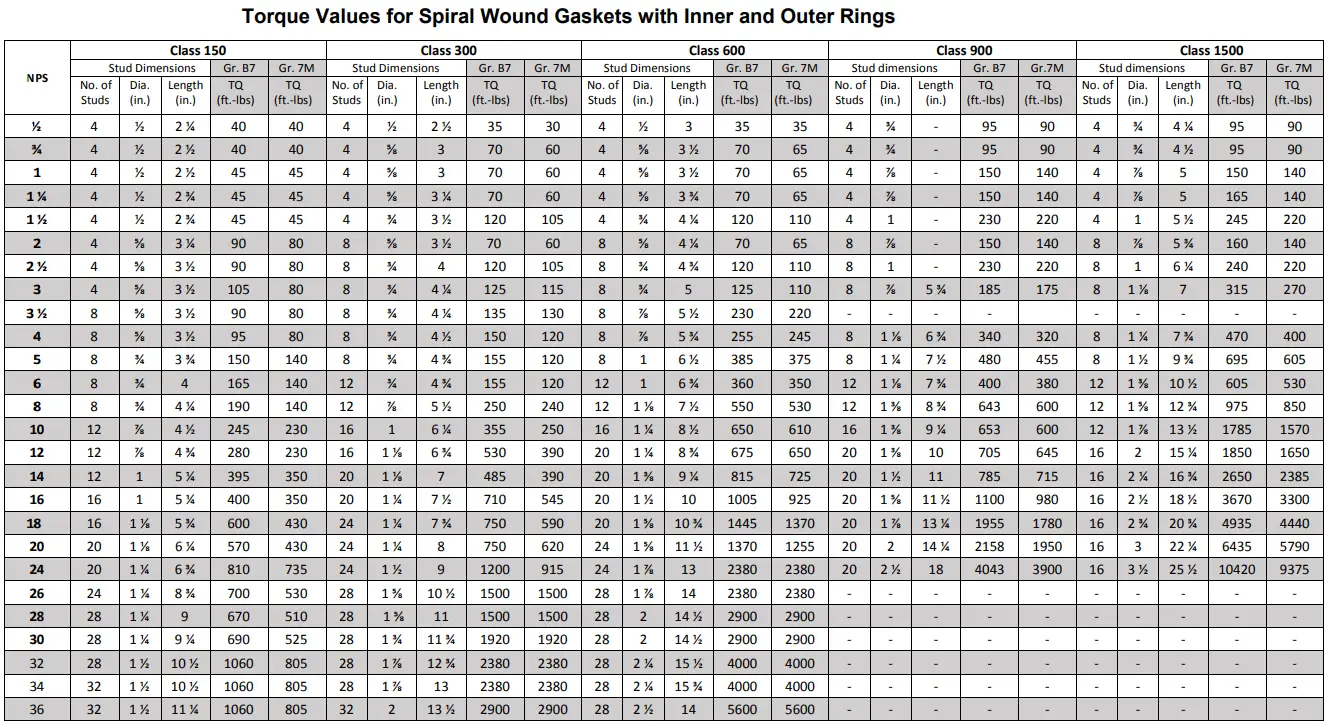

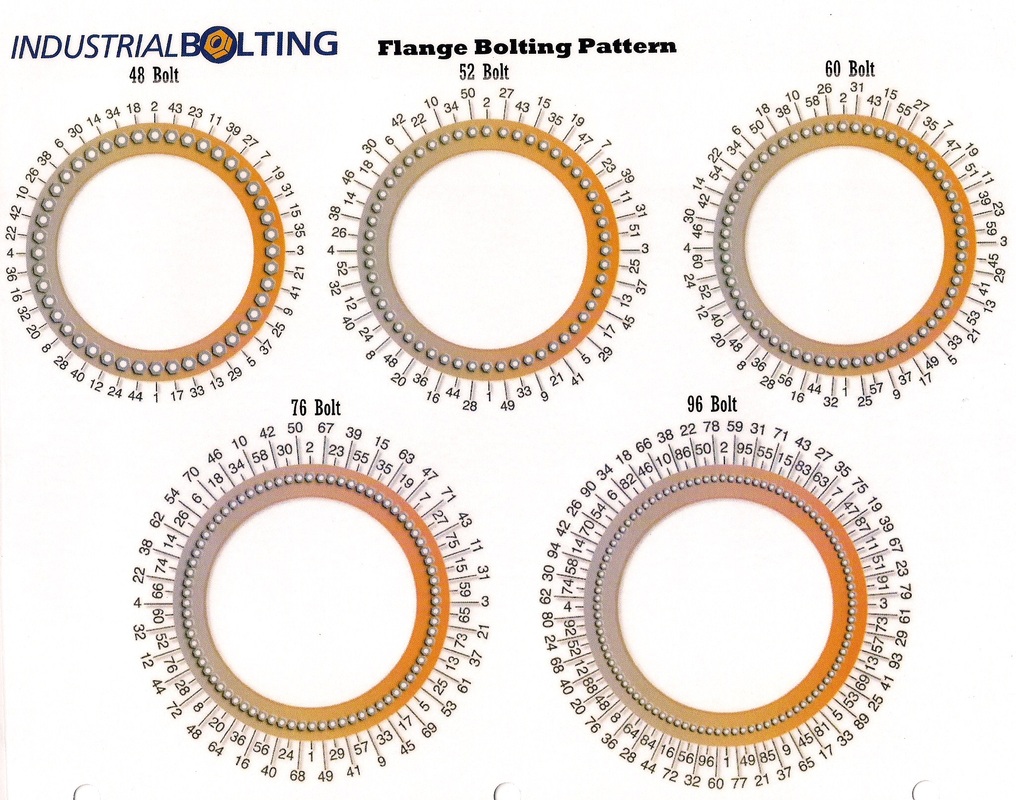

Torque Flange Chart - Links to the flange torque charts maintained by flange bolt chart for class 600 flanges. * use this the data from this program at your own. Lookup bolt lengths, wrench sizes,. This torque creates an axial force in the bolt. Flange assembly must be done with proper care. Flange bolt size chart and torque patterns. Web based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.*** rec. Web when the gasket extends past the o.d. Sealing for a safer and greener tomorrow. See bottom of page for calculation details. Inch metric ansi b16.5 api 6a. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Follow flange bolt torque values for proper tightness. The user must confirm that torque values do not exceed pipe manufacturer’s torque recommendation. Web look up flange bolt sizes and torque patterns in three taps with flange bolt. Web look up flange bolt sizes and torque patterns in three taps with flange bolt. The user must verify these conditions, as outlined, are appropriate for the specific application. Web this table provides an estimation of torque for use during assembly of standard design steel pipe flanges. Bolt materials listed are per asme a193. See bottom of page for calculation. * use this the data from this program at your own. Bolt materials listed are per asme a193. Torque tables for the installation of flat gaskets with standard asme flanges. 435 psi hydro test pressure: Web flange bolt torque calculation formula. Target % of yield ? Torque tables for the installation of flat gaskets with standard asme flanges. See bottom of page for calculation details. This torque creates an axial force in the bolt. Target residual stresses apply to standard pipe flanges that are fabricated in accordance with asme b16.5. Web flange insulation bolt torque recommendations. Central plastics company does not take responsibility for any of these torque values, they're theoretical values. The bolt tightening sequence is common to all flange, regardless of the material. By nominal pipe size (nps) nps 0.5. Ansi 150# flanges ansi 300# flanges ansi 400# flanges. Web flange bolt torque sequence. By nominal pipe size (nps) nps 0.5. * use this the data from this program at your own. 455 psi hydro test pressure: The bolt tightening sequence is common to all flange, regardless of the material. Central plastics company does not take responsibility for any of these torque values, they're theoretical values. Web flange insulation bolt torque recommendations. Using a calibrated torque wrench (manual or hydraulic torque wrench), flange bolt torque can be measured during flange assembly. Web flange bolt torque calculation formula. Flange bolt size chart and torque patterns. Web when the gasket extends past the o.d. 435 psi hydro test pressure: Target % of yield ? Sealing for a safer and greener tomorrow. Flange joints are torqued tight with the help of a torque wrench (manual or hydraulic). Web flange bolt torque table. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: Follow flange bolt torque values for proper tightness. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Web based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.*** rec. 1135 psi hydro test pressure: 1135 psi hydro test pressure: Web flange insulation bolt torque recommendations. Follow the bolt tightening sequence. Flange assembly must be done with proper care. Flange assembly must be done with proper care. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: Web based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.*** rec. 1135 psi hydro test pressure: Web flange bolt torque table. Lookup bolt lengths, wrench sizes,. Links to the flange torque charts maintained by flange bolt chart for class 600 flanges. Lbs ansi 150# flanges ansi 300# flanges ansi 600# flanges rec. Of the flange by 1/4:” to 3/8”, stop tightening. By nominal pipe size (nps) nps 0.5. 435 psi hydro test pressure: Do not exceed the recommended bolt torque. This document presents the recommended bolt torque in accordance with size and flange material: Bolt torque is the twisting or turning force applied to tighten the nut on a bolt. The user must verify these conditions, as outlined, are appropriate for the specific application.Flange Torque values.pdf Gas Technologies Mechanical Engineering

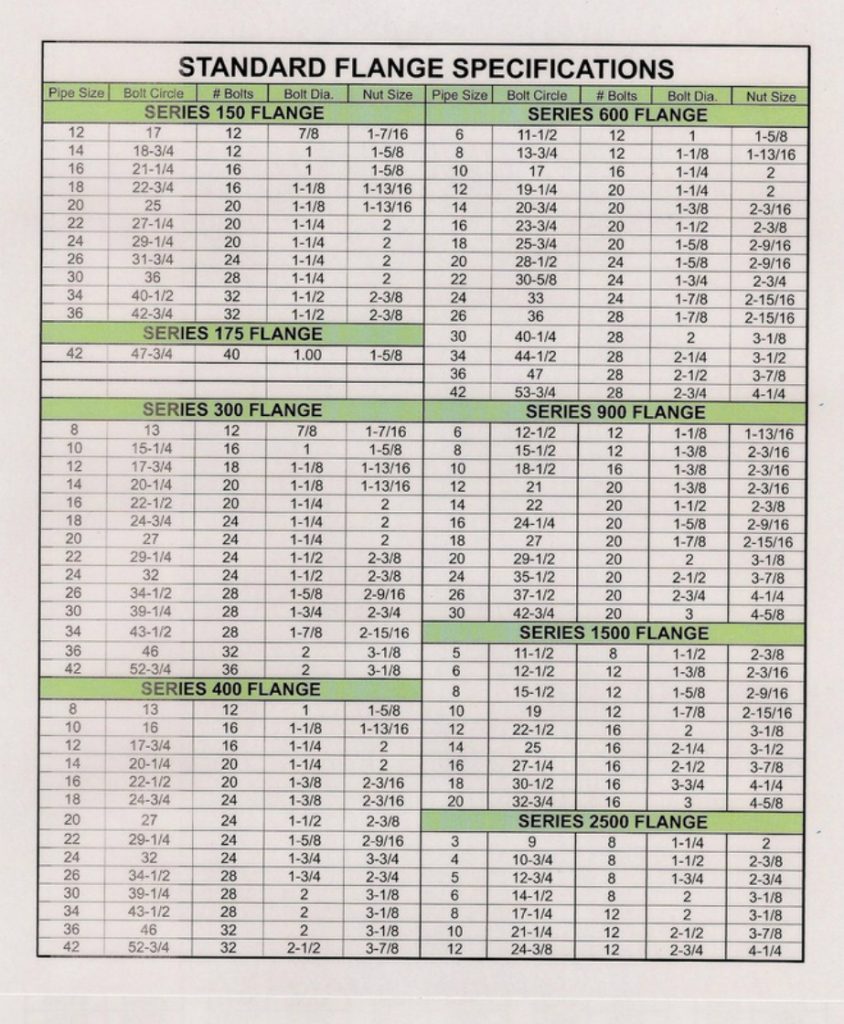

Flange Bolt Torque Specification Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Flange Bolt Torque Specification Chart

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Torque Charts Industrial Torque Tools

Stud Bolt Torque Chart Images and Photos finder

Flange Bolt Torque Specification Chart

Torque Charts Industrial Bolting and Torque Tools

Flange Torque GF.pdf Gas Technologies Mechanical

Web This Table Provides An Estimation Of Torque For Use During Assembly Of Standard Design Steel Pipe Flanges.

Target Bolt Residual Stress (Raised Face Flanges) Notes:

Web Pipe Size Of Bolts Torque Torque Torque Torque Torque Torque Torque Torque Torque Torque (Inches) Bolts (Inches) (Ft.lbs.) (Ft.lbs.) (Ft.lbs.) (Ft.lbs.) (Ft.lbs.) (Ft.lbs.) (Ft.lbs.) (Ft.lbs.) (Ft.lbs.) (Ft.lbs.) 0.5 4 0.50 16 47 17 52 8 42 18 53 0.75 4 0.63 28 84 29 88 14 68 31 92 1 4 0.63 38 114 38 115 17 84 34 102

Central Plastics Company Does Not Take Responsibility For Any Of These Torque Values, They're Theoretical Values.

Related Post: