Welding Amperage Chart

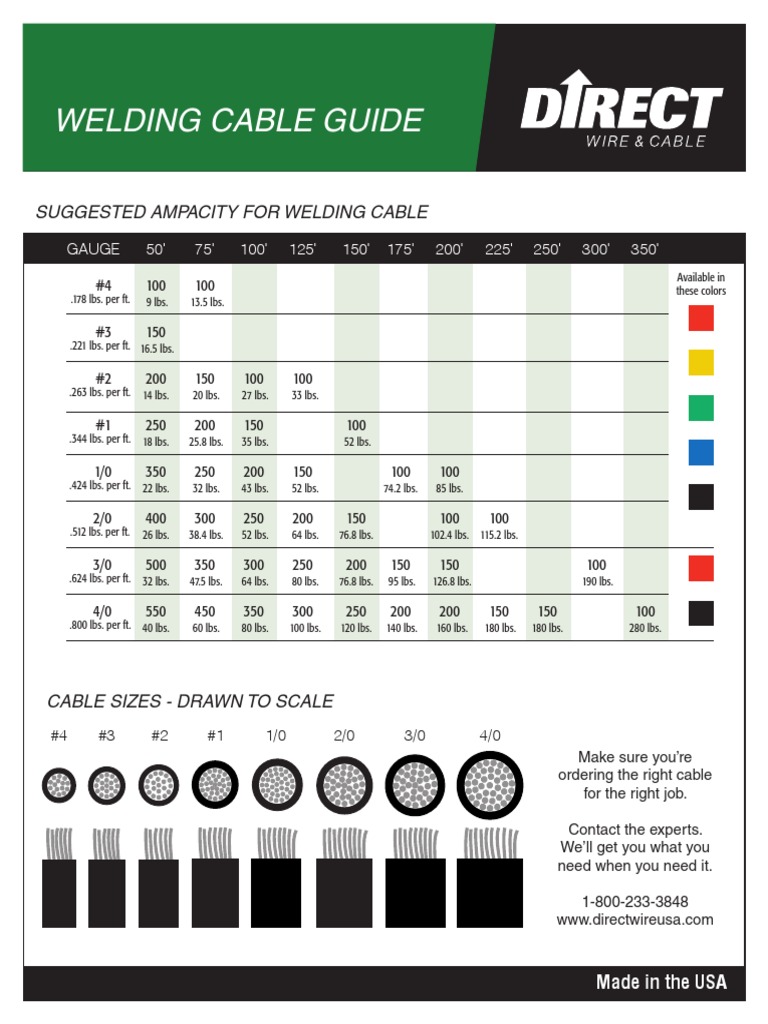

Welding Amperage Chart - You might also find our welding calculators useful. What metal are you welding? E7024 size and amperage chart; Additionally, we made the most complete stick welding rod chart pdf on the internet with over 220 electrodes. Do not wear wet or damaged gloves. There is a certain range of current (amperage) that must be used with. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. This help determines what the various options are designed for and which ones should be used at different times. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Do not use near water or damp objects. This help determines what the various options are designed for and which ones should be used at different times. Browse suggested weld parameter settings for tig welding. There is a certain range of current (amperage) that must be used with. E308l stainless steel welding rod chart; E7014 size and amperage chart; Direct wire’s welding cable ampacity chart intends to support and guide welding professionals toward the proper cable gauge and length. There might be variations with the settings depending on the manufacturer. What are the common sizes of tig welding rods? Browse suggested weld parameter settings for tig welding. Web jump to ampacity chart. Fundamental knowledge, practical inspection, and codebook navigation. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Once you determine these three main variables, you can set your welding machine and start. That's because as the welding current increases, the weld penetrates deeper into the base. Web holder, electrode, welding torch, or welding wire with bare hand. For many contractors, stick welding is at the heart of their business. The chart provides a visual representation of the required settings, making it easy for welders to select the right amperage, depending on the material, joint type, electrode size, and welding position. This help determines what the various. Earning your certified welding inspector (cwi) credential is serious work and has a significant impact on your future. Direct wire’s welding cable ampacity chart intends to support and guide welding professionals toward the proper cable gauge and length. Do not use near water or damp objects. So what are the other letters and numbers on the label? Web weld setting. Flux composition & current chart; You will also get the required polarity, position, and other related information. Choosing the right welding cable. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. You might also find our welding calculators useful. Web to understand the procedure of sanitary welding, we must first know the process of tig ( tungsten inert gas) welding or gtaw ( gas tungsten arc welding) and orbital welding. Electrode amperage chart | types and thicknesses. You will also get the required polarity, position, and other related information. 7014 welding rod amperage chart. Web holder, electrode, welding torch,. Web to understand the procedure of sanitary welding, we must first know the process of tig ( tungsten inert gas) welding or gtaw ( gas tungsten arc welding) and orbital welding. So what are the other letters and numbers on the label? Web welding rod sizes with amperage chart. By referring to the recommended amperage range for each stick welding. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. That's because as the welding current increases, the weld penetrates deeper into the base material. What are the common sizes of tig welding rods? Web what material are you welding? Direct wire’s welding cable ampacity chart. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. Do not use near water or damp objects. Web to understand the procedure of. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: What metal are you welding? Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Amperage setting is very critical to weld quality as it directly affects the shape of the weld pool. You can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding. Take a look at table 1: The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. The table is published in aws a5.1 specification. Do not use near water or damp objects. Web learn the basics of welding: Web if you are searching for a quick and easy guide for common metals, here is an excellent mig welding amperage chart to reference. Web to understand the procedure of sanitary welding, we must first know the process of tig ( tungsten inert gas) welding or gtaw ( gas tungsten arc welding) and orbital welding. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. Web welding rod sizes with amperage chart. E7018 size and amperage chart; Web weld setting calculator app.

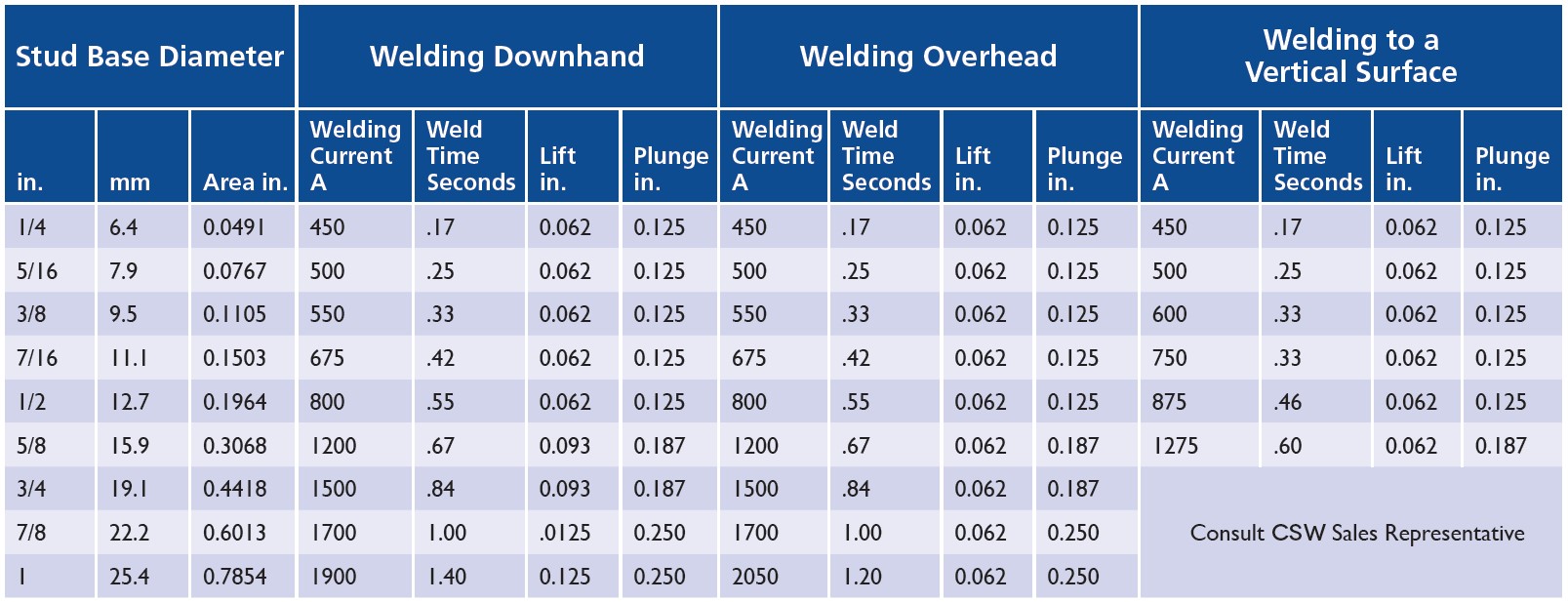

Arc Stud Welding Complete Stud Weld

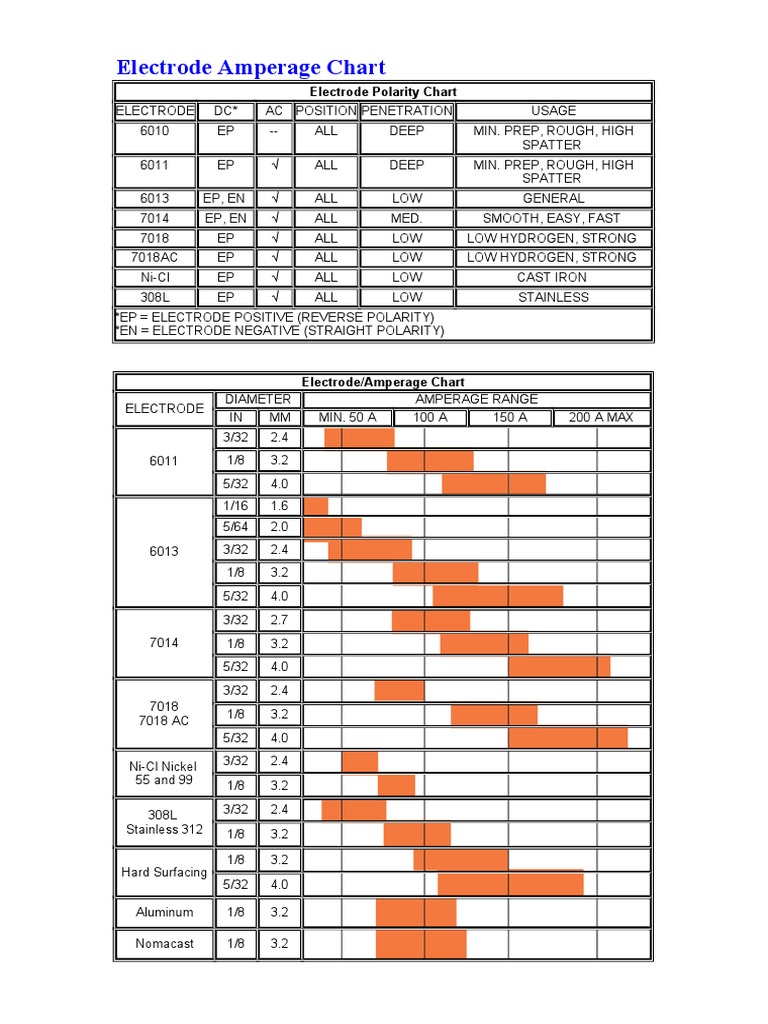

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

Stick Welding Electrode Chart

Electrode Amperage Chart

Welding Cable Size Amperage Chart

TIG Welding Amperage Chart Simpleweld

Avoiding arc start porosity on 7018? Page 2

How to Prevent Welding Rod Sticking to The Metal Welding Tribe

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

MIG welder settings explained Amperage & Wire Speed

Do Not Wear Wet Or Damaged Gloves.

Once You Determine These Three Main Variables, You Can Set Your Welding Machine And Start.

Flux Composition & Current Chart;

That's Because As The Welding Current Increases, The Weld Penetrates Deeper Into The Base Material.

Related Post: