Welding Polarity Chart

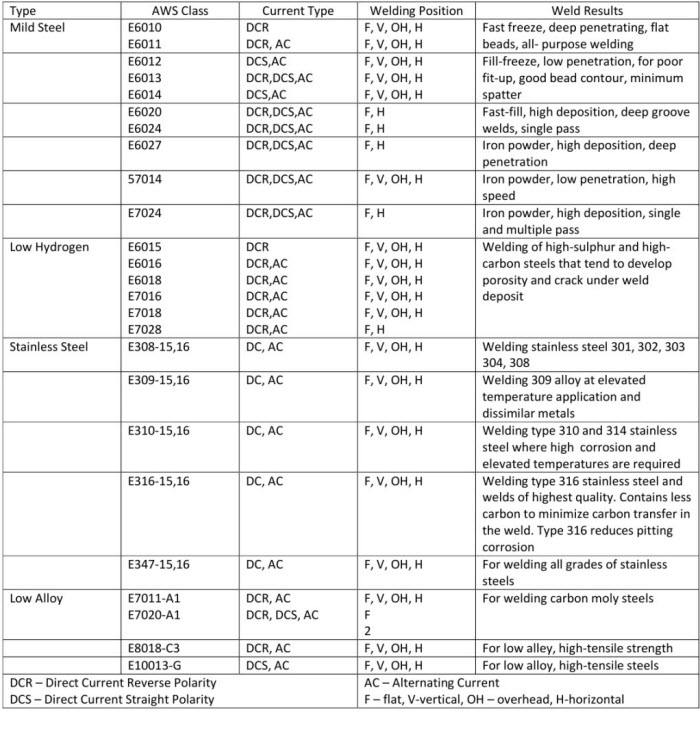

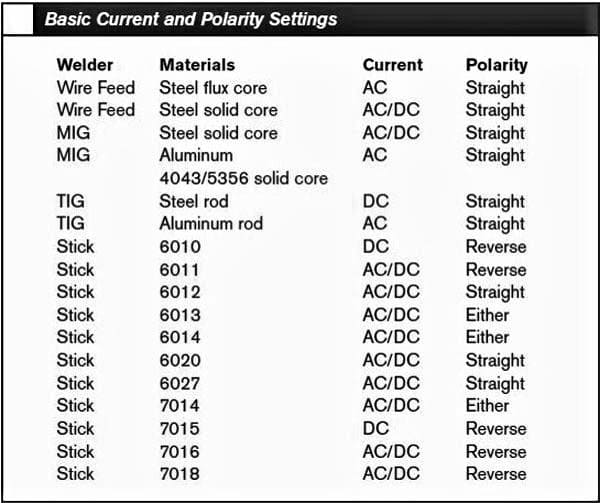

Welding Polarity Chart - Processes like stick welding require a different polarity type, which we’ll get into below. Web the tig welding polarity comes with two different types. Web july 7, 2023 by sandeep kumar. It is made out of materials with a similar composition to the metal being welded. Almost all unimig machines are suitable for stick welding, as the torch attaches into the panel mount, which both mig and tig machines are equipped with. What polarity is stick welding? Use ac (alternating current) when welding aluminum and magnesium. If the welder uses the wrong polarity, they can either overheat or underheat the metal, which can lead to problems like warping, melting, or even explosions. This property is called polarity. Web in most cases, dc is the preferred welding polarity. Ac welding and dc welding. Plus, a mig welding polarity chart can help you troubleshoot any problems you may be having with your welds. Welders should be aware of the different types of polarity and how they can affect the quality of their welds. Polarity matters greatly in welding because choosing the right polarity affects the strength and quality of. This way, you can quickly and easily find the right setting for your project. When you connect the gun cable to your welder’s positive (+) terminal, we call the polarity dcep, also known as reverse polarity, and known in full as. Web see the chart below for recommended flow rates. Positive polarity (dcep) #1 choice. Direct current electrode negative (dcen). Figure 1 is a graph of dc welding output vs. Gas flow rates for tig welding. Stick welding polarity is the direction of the current flow through the electrode and workpiece. This post contains affiliate links. It’s important to understand polarity as it’ll affect electrode consumption and its melting rate, heat distribution in your parent metal, and what your weld. Web july 7, 2023 by sandeep kumar. The dc and ac tig welding polarities. Processes like stick welding require a different polarity type, which we’ll get into below. Electrodes for copper and copper alloys. Web a welder should know the meaning of polarity, and recognize what effect it has on the welding process. It’s important to understand polarity as it’ll affect electrode consumption and its melting rate, heat distribution in your parent metal, and what your weld bead will finally look like. Polarity matters greatly in welding because choosing the right polarity affects the strength and quality of the weld. Use ac (alternating current) when welding aluminum and magnesium. Welding polarities include electrode. The electronegative dcen and the electropositive dcep. Web a mig welding polarity chart lists the different types of metal and the recommended polarity setting for each. Web some electrodes can run on both ac, dcep, and dcen polarities while some are good only with dcep or dcen. Web polarity is the electrical circuit created between a welder’s positive and negative. Web welding polarity chart. Web polarity refers to the direction of electrical current flow between your welding electrode and your work clamp that completes the welding electrical circuit. Electrodes for copper and copper alloys. Direct current electrode negative (dcen) and direct current electrode positive (dcep). The electronegative dcen and the electropositive dcep. The pdf has 8 sections: Web mar 12, 2021 · 5 min read. Figure 1 is a graph of dc welding output vs. The most common type of welding polarity is direct current (dc), which flows in one direction. Is the tig electrode positive or negative? Web a welder should know the meaning of polarity, and recognize what effect it has on the welding process. Direct current electrode negative (dcen) and direct current electrode positive (dcep). Welding polarities include electrode positive polarity or dcep and dcen or electrode negative polarity. Web mar 12, 2021 · 5 min read. Plus, a mig welding polarity chart can help. Tig electrode is kept as negative. Web what is polarity in welding? When you connect the gun cable to your welder’s positive (+) terminal, we call the polarity dcep, also known as reverse polarity, and known in full as. Processes like stick welding require a different polarity type, which we’ll get into below. Web polarity is the electrical circuit created. Web stick welding polarity chart. Direct current electrode negative (dcen) and direct current electrode positive (dcep). Both of them come with respective subtypes; Web a welder should know the meaning of polarity, and recognize what effect it has on the welding process. Web mar 12, 2021 · 5 min read. It’s important to understand polarity as it’ll affect electrode consumption and its melting rate, heat distribution in your parent metal, and what your weld bead will finally look like. Web some electrodes can run on both ac, dcep, and dcen polarities while some are good only with dcep or dcen. Tig electrode is kept as negative. Web mig welding polarity chart. If the welder uses the wrong polarity, they can either overheat or underheat the metal, which can lead to problems like warping, melting, or even explosions. Here’s a brief explanation of the table: Web in most cases, dc is the preferred welding polarity. Web polarity is the electrical circuit created between a welder’s positive and negative poles when they turn on their welder. Web see the chart below for recommended flow rates. An electrode is a metal wire that is coated. Electrodes for low alloy steel.

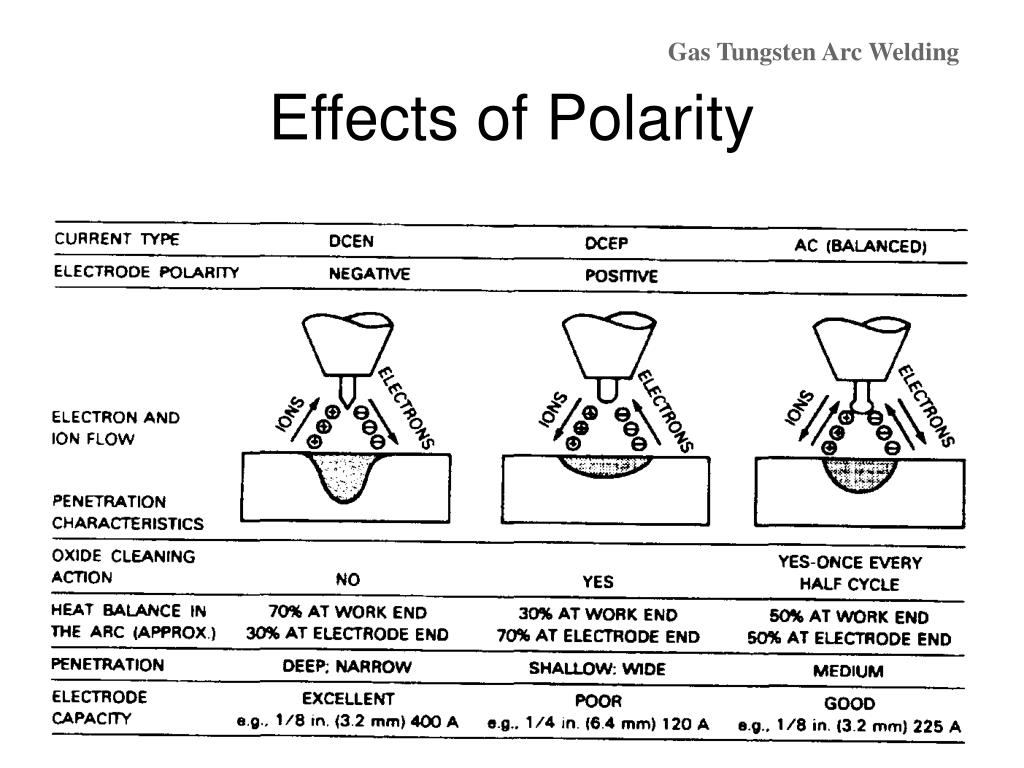

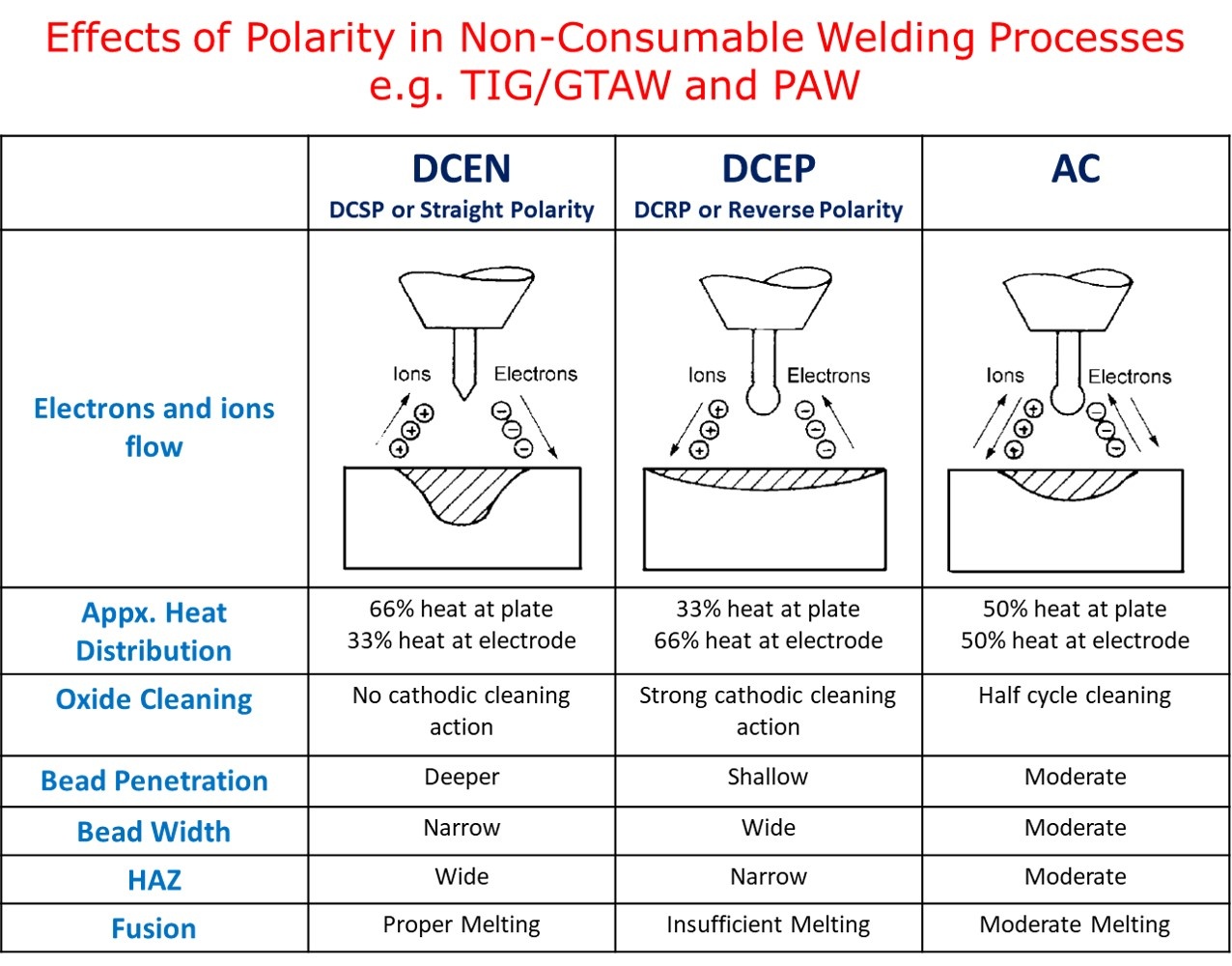

Differences Between DCEN Polarity and DCEP Polarity in Arc Welding

TIG Welding Polarity A Beginners Guide Welders Manual

![How To Properly Set Your MIG Welding Polarity Settings [Updated]](https://weldingtroop.com/wp-content/uploads/2020/05/DC-Polarity-SMAW-Chart.jpg)

How To Properly Set Your MIG Welding Polarity Settings [Updated]

PPT Gas Tungsten Arc Welding (GTAW or TIG) PowerPoint Presentation

Which is better electrode polarity welding? Difference between DCEN

Arc Welding Rods Guide

Tig Welding Polarity Chart

Electrodes and Amps

Effect of polarity switching in TIG welding /ASM 1993/. Download

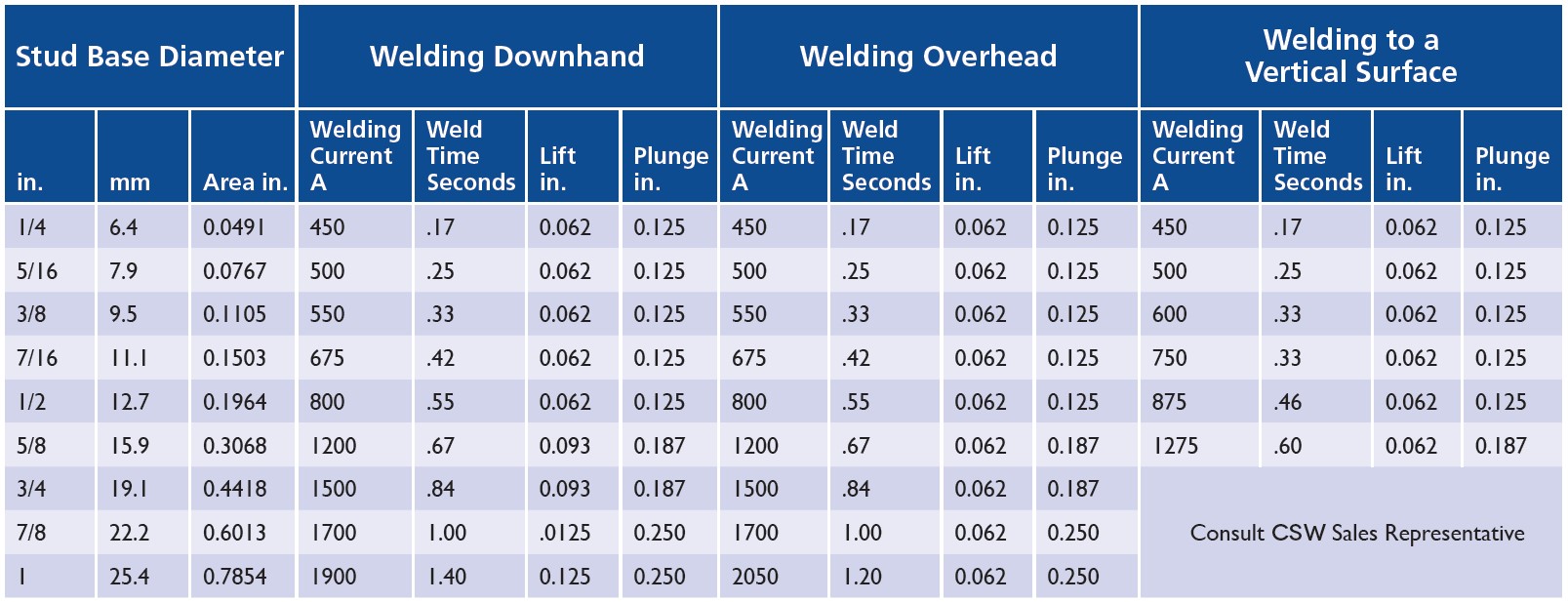

Arc Stud Welding Complete Stud Weld

The Welding Electrode Polarity Chart For Stick Welding Electrodes E6010, E6012, E6013, E7014, E7015, E7018, And E7024 Is Shown In The Below Picture.

Processes Like Stick Welding Require A Different Polarity Type, Which We’ll Get Into Below.

This Way, You Can Quickly And Easily Find The Right Setting For Your Project.

Web In This Welding Rod Chart, You Will Find Over 220 Stick Electrodes Classified According To The American Welding Society (Aws) Code.

Related Post: