Welding Rod Size Chart

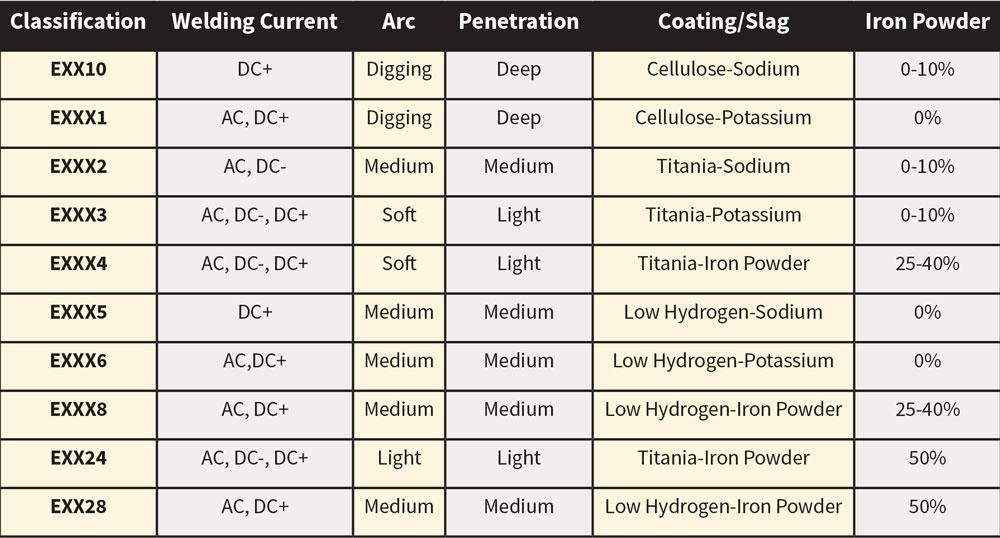

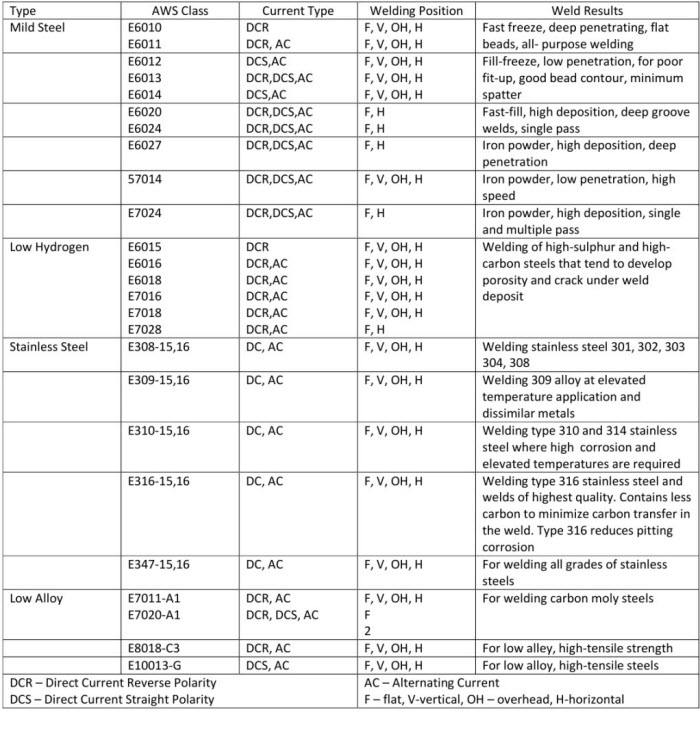

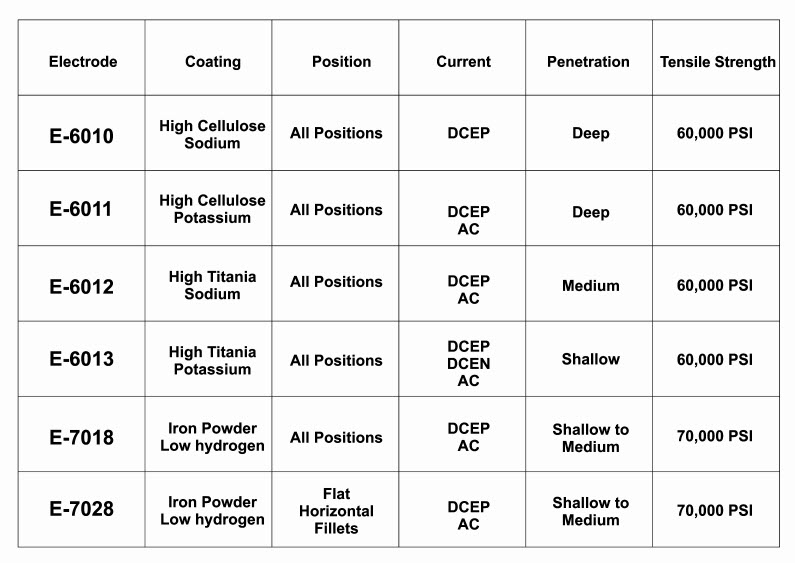

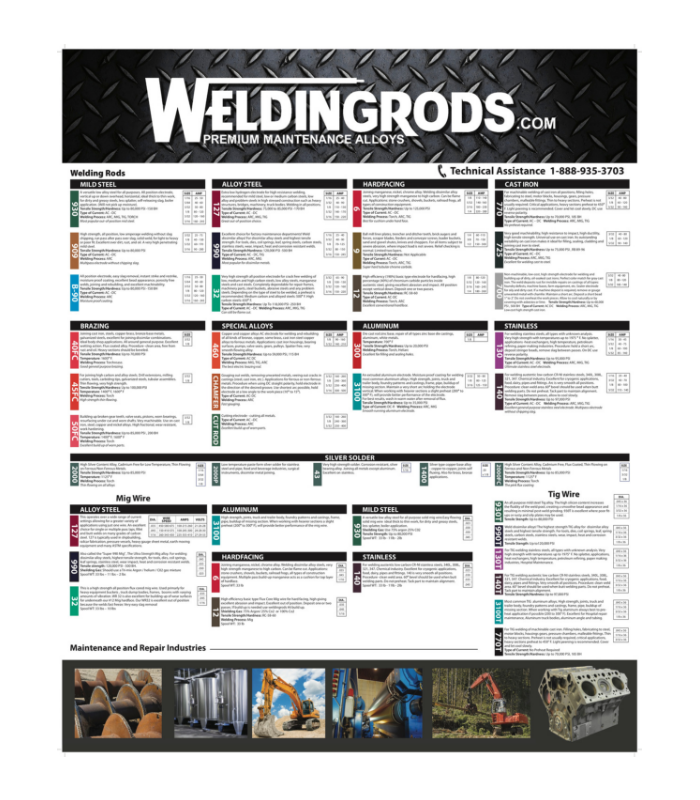

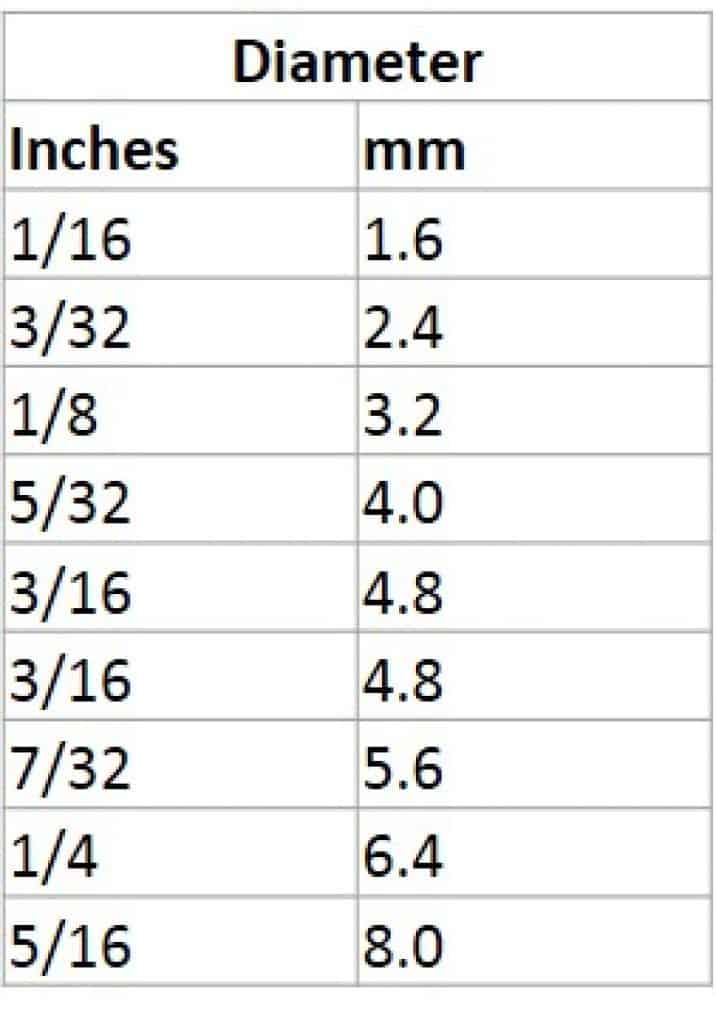

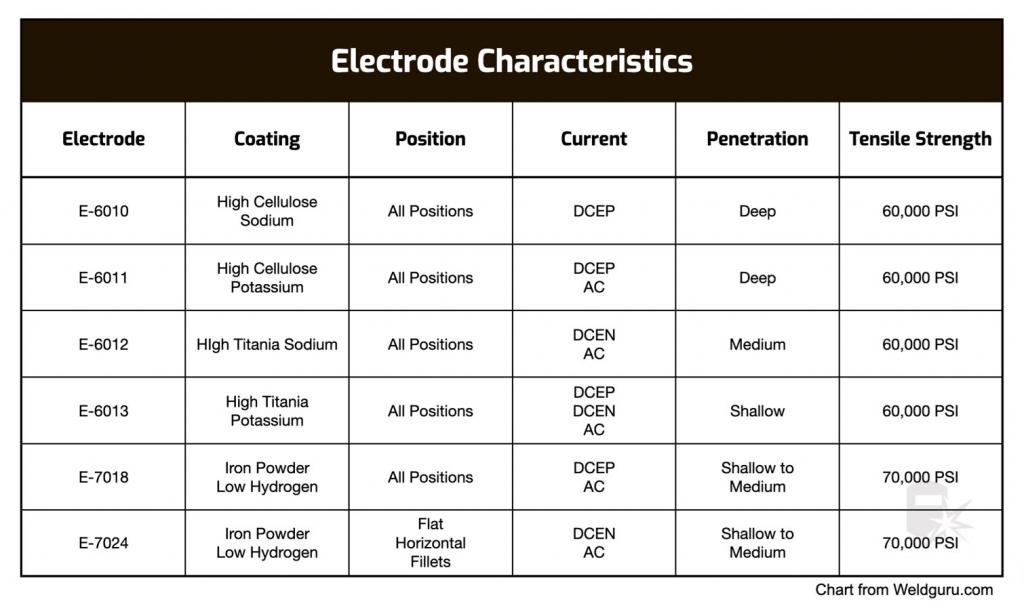

Welding Rod Size Chart - How to select amperage for a stick welding rod? Click here to see the welding rod chart in pdf format. Web include diese welding rod chart, you will find over 220 sticking electrodes classified according to the american welding society (aws) code. Electrical for copper and copper alloys. Now let’s explain that relationship in physical terms. E7018 size and amperage chart; For example, a 1/8” (3.2 mm) 7018 electrode will have more flux and a larger outer diameter than a 1/8” 7011 electrode. What is the right rod size for you and how do you pick the right welding electrode? E6012 size and amperage chart; Web the welding rod diameter is measured from the metal core. Stick welding rod sizes vary from 1/16 inch, or 1.4 mm, up to 1/4 or 6.4 mm and over. Understanding stick welding rod classification is essential in selecting the correct electrode for your welding needs. Larger welding electrodes are only really needed for welding 1/2” and above, so won’t be used on most home welding projects. The required amperage to. The pdf has 8 section: Know about the tensile strength of metals. It is made out of materials with a similar composition to the metal being welded. Before we go deeper into welding rod sizes, including their uses, let’s discuss welding rod classification. The third digit, on the other hand, refers to the number of positions in which the welding. Know about the tensile strength of metals. These are identified as “tig cut lengths.” choosing a filler rod. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. The third digit, on the other hand, refers to the number of positions in which the welding rod can be used. There are a. Contents [ show] common stick welding rods. Web they are 6010, 6011, 6012, 6013, while the rest is 7014, 7018, and 7024. Web welding rods come in various sizes and gauges, from.035″ to.110″, and each has its specific purpose. Application for welding rod sizes. What are the most common stick rods for home welding? The reason for this is that the total outer diameter will vary depending on the thickness of the flux coating. These are identified as “tig cut lengths.” choosing a filler rod. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. Electrodes for copper and copper alloys; The chart above indicates the. Before we go deeper into welding rod sizes, including their uses, let’s discuss welding rod classification. E7014 size and amperage chart; E6012 size and amperage chart; Now let’s explain that relationship in physical terms. The pdf has 8 section: Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. These are identified as “tig cut lengths.” choosing a filler rod. There are a variety of factors that go into choosing the right electrode for. The third digit, on the other hand, refers to the number of positions in which the welding. We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. View posters and charts with technical guidance on handling, storage and applications for hobart brothers filler metal solutions. E7018 size and amperage chart; Electrical for copper and copper alloys. To determine. How to choose the correct stick welding rod size? Application for welding rod sizes. Electrodes to low alloy steel. It is made out of materials with a similar composition to the metal being welded. These are identified as “tig cut lengths.” choosing a filler rod. Larger welding electrodes are only really needed for welding 1/2” and above, so won’t be used on most home welding projects. Know about current and polarity. Web in this welding rod chart, you will find over 220 stick electrodes classified according to the american welding society (aws) code. Web the diameter usually ranges from 1/16 to 1/4 inch. What is. Electrodes for copper and copper alloys; Web the diameter usually ranges from 1/16 to 1/4 inch. The pdf has 8 sections: Larger welding electrodes are only really needed for welding 1/2” and above, so won’t be used on most home welding projects. The required amperage to use these electrodes might also be too high because many portable stick welders only. These are identified as “tig cut lengths.” choosing a filler rod. Electrical for copper and copper alloys. Know about current and polarity. Click here to see the welding rod chart in pdf format. We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your welding team. The reason for this is that the total outer diameter will vary depending on the thickness of the flux coating. The third digit, on the other hand, refers to the number of positions in which the welding rod can be used. The chart above indicates the numerical relationship between amperes and welding rod sizes. Web table of contents. How to select amperage for a stick welding rod? Before we go deeper into welding rod sizes, including their uses, let’s discuss welding rod classification.

Search Result Details Welding rods, Welding tips, Welding videos

ER309L TIG Stainless Steel Welding Rod 36" All Sizes (Pack 1

Stick electrode and welding basics

Welding Rod Chart

Arc Welding Rods Guide

Arc Welding Rods Guide

Welding Rod List

Welding Rod Chart

Welding Rods for Stick Welding The Definitive Electrode Guide (2019)

Welding Rods Compared 6010, 6011, 6013, 7018 & 7024

It Is Made Out Of Materials With A Similar Composition To The Metal Being Welded.

1/8” And 5/32” Are Also Very Common.

Web The Most Popular Welding Rods For Hobbyists Are 3/32” Rods.

Web Welding Rod Sizes Explained.

Related Post: