Welding Wire Size Chart

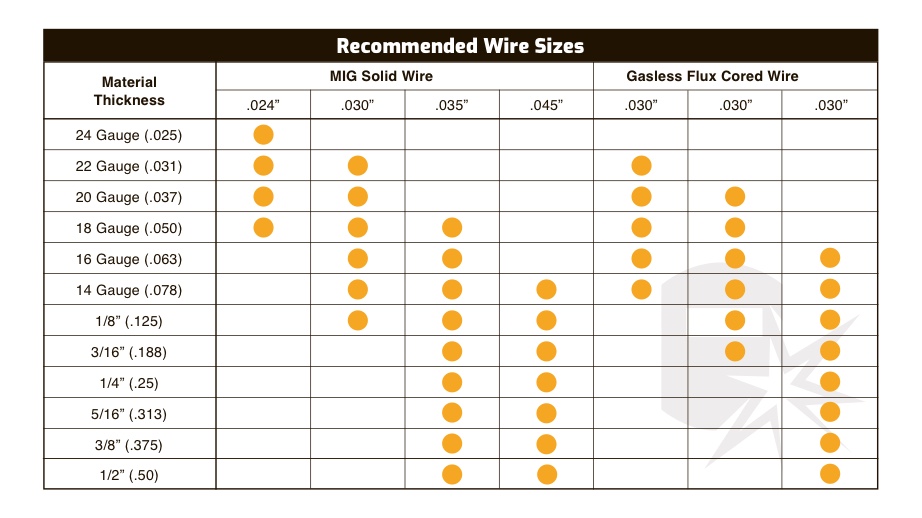

Welding Wire Size Chart - Different welding cables will have different amp ratings depending on several factors: 24 gauge (.025) 22 gauge (.031) 20 gauge (.037) 18 gauge (.050) 16 gauge (.063) 14 gauge (.078) 1/8 (.125) 3/16 (.188) 1/4 (.25) 5/16 (.313) 3/8 (.375).024 mig solid wire. The ampacity, or amperage capacity, is the maximum amount of electrical current that the welding cable can conduct safely. Web recommended welding wire size chart. Gauge (or gage) sizes larger than one are zero, also expressed as 1/0 (pronounced “one aught”), two zeros, expressed as 2/0 (pronounced two aught), 3/0 and 4/0. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Optimize your welding projects with the welding wire size calculator. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using guidance from aws f4.2:2020 handbook. Web by selecting the material type, joint type, and desired wire diameter, you can obtain a recommended welding wire size that aligns with industry standards and ensures the success of your welds. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. The ampacity, or amperage capacity, is the maximum amount of electrical current that the welding cable can conduct safely. Optimize your welding projects with the welding wire size calculator. Web the most common sizes for welding on sheet metal are 0.35 and. Optimize your welding projects with the welding wire size calculator. The ampacity, or amperage capacity, is the maximum amount of electrical current that the welding cable can conduct safely. Cable length, wire size (gauge), resistance rating. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. Higher amperage and longer lead lengths. Higher amperage and longer lead lengths require larger diameter cables (lower awg number) to minimize voltage drop, resistance, and cable overheating. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using guidance from aws f4.2:2020 handbook. Web use the american wire gauge. Web february 26, 2024november 28, 2023 by sohagarbin. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Cable length, wire size (gauge), resistance rating. Selecting the appropriate mig wire size is crucial for successful welding. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Web recommended welding wire size chart. For a hobby welder using less than 240 amps and less than 50 ft in combined cable length, a 1 gauge welding lead is. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. A mig wire. Gauge (or gage) sizes larger than one are zero, also expressed as 1/0 (pronounced “one aught”), two zeros, expressed as 2/0 (pronounced two aught), 3/0 and 4/0. Different welding cables will have different amp ratings depending on several factors: Web use the american wire gauge (awg) chart as a reference. Cable sizes between #4 and #4/0 are typically used for. Optimize your welding projects with the welding wire size calculator. Web recommended welding wire size chart. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Web figure 1 lists the awg sizes. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Cable sizes between #4 and #4/0 are typically used for welding cable. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Use this calculator to enhance the precision and. Optimize your welding projects with the welding wire size calculator. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using guidance from aws f4.2:2020 handbook. Selecting the appropriate. Web recommended welding wire size chart. The ampacity, or amperage capacity, is the maximum amount of electrical current that the welding cable can conduct safely. Use this calculator to enhance the precision and efficiency of your welding work. Web use the american wire gauge (awg) chart as a reference. Web figure 1 lists the awg sizes. 24 gauge (.025) 22 gauge (.031) 20 gauge (.037) 18 gauge (.050) 16 gauge (.063) 14 gauge (.078) 1/8 (.125) 3/16 (.188) 1/4 (.25) 5/16 (.313) 3/8 (.375).024 mig solid wire. For a hobby welder using less than 240 amps and less than 50 ft in combined cable length, a 1 gauge welding lead is. Cable length, wire size (gauge), resistance rating. Optimize your welding projects with the welding wire size calculator. Gauge (or gage) sizes larger than one are zero, also expressed as 1/0 (pronounced “one aught”), two zeros, expressed as 2/0 (pronounced two aught), 3/0 and 4/0. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. Web figure 1 lists the awg sizes. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Selecting the appropriate mig wire size is crucial for successful welding. The ampacity, or amperage capacity, is the maximum amount of electrical current that the welding cable can conduct safely. Different welding cables will have different amp ratings depending on several factors: Higher amperage and longer lead lengths require larger diameter cables (lower awg number) to minimize voltage drop, resistance, and cable overheating. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. Cable sizes between #4 and #4/0 are typically used for welding cable. Web recommended welding wire size chart.

MIG + Flux Core Welding Wire Size Chart Beginner Welding Guide

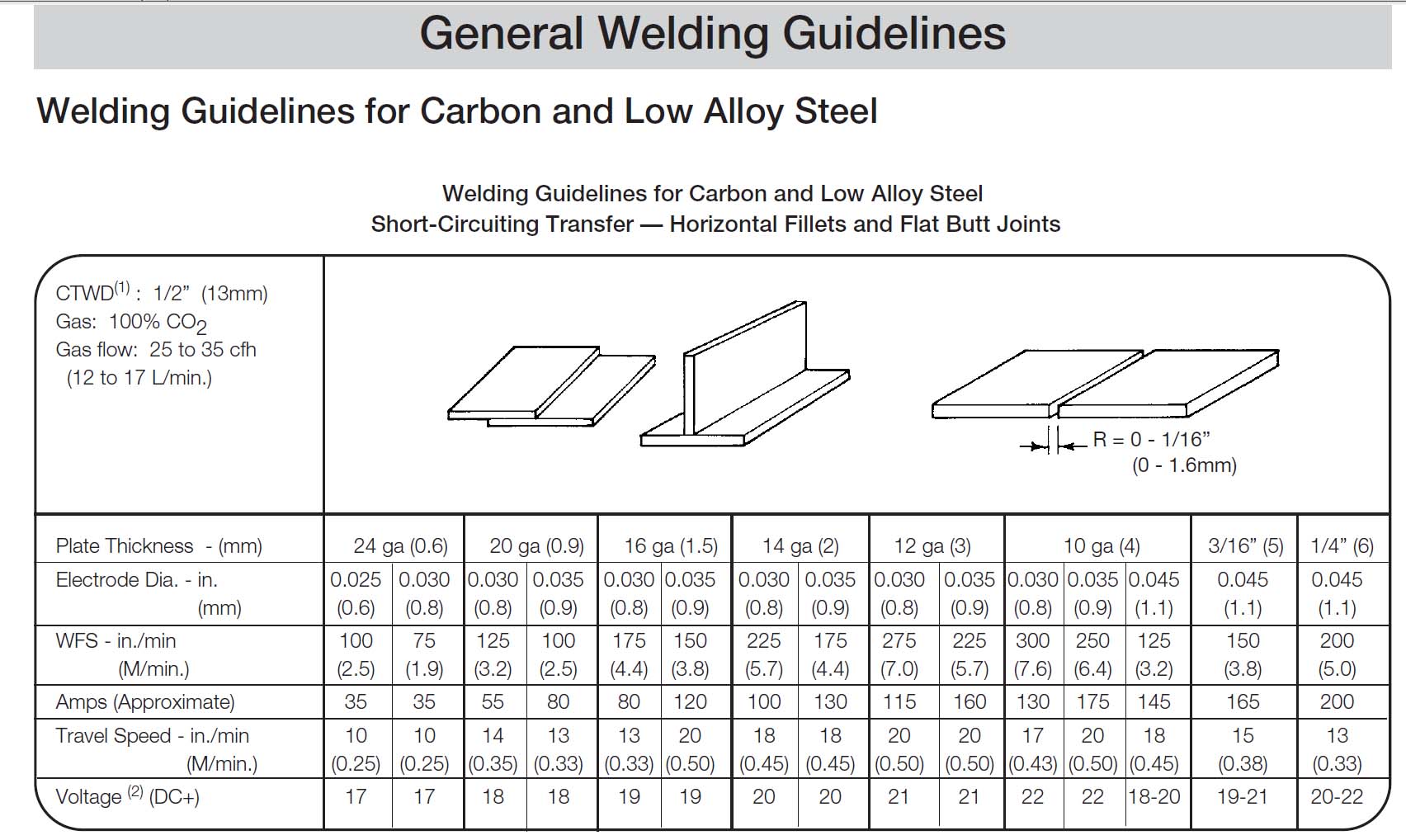

MIG settings for welding different thickness mild steel

WeightofWeldMetalRequired General Air

Airgas

MIG + Flux Core Welding Wire Size Chart Beginner Welding Guide

How To Hook Up Stick Welding Leads Welders Cave

Welding Wire Size Chart Mechanic's Corner Pinterest Wire, Charts

Welding Cable Size Chart ubicaciondepersonas.cdmx.gob.mx

welding cable ampacity chart Aria Story

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

Web In This Article, We’ll Navigate The Key Points, From Deciphering Cable And Lead Size Charts To Pinpointing The Exact Cable Size That Fits Your Specific Needs Using Guidance From Aws F4.2:2020 Handbook.

Web February 26, 2024November 28, 2023 By Sohagarbin.

Web Use The American Wire Gauge (Awg) Chart As A Reference.

Web By Selecting The Material Type, Joint Type, And Desired Wire Diameter, You Can Obtain A Recommended Welding Wire Size That Aligns With Industry Standards And Ensures The Success Of Your Welds.

Related Post: