Wheel Bearing Torque Chart

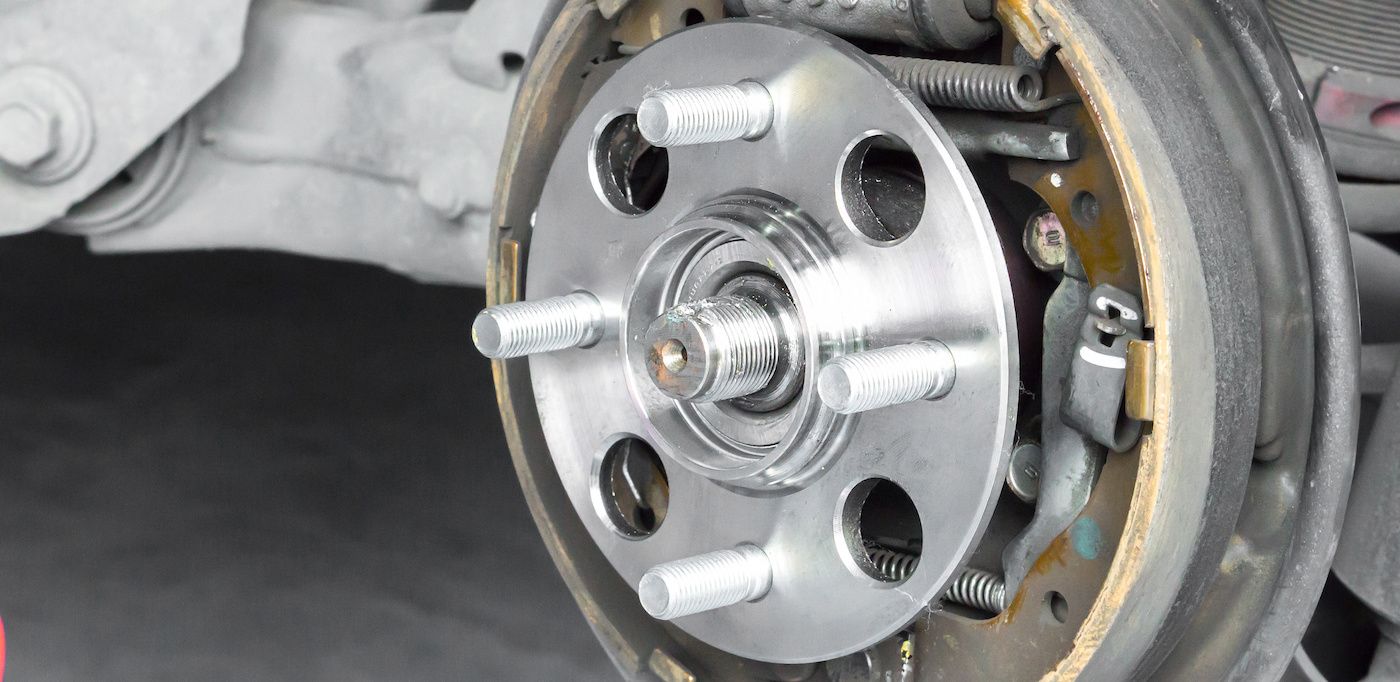

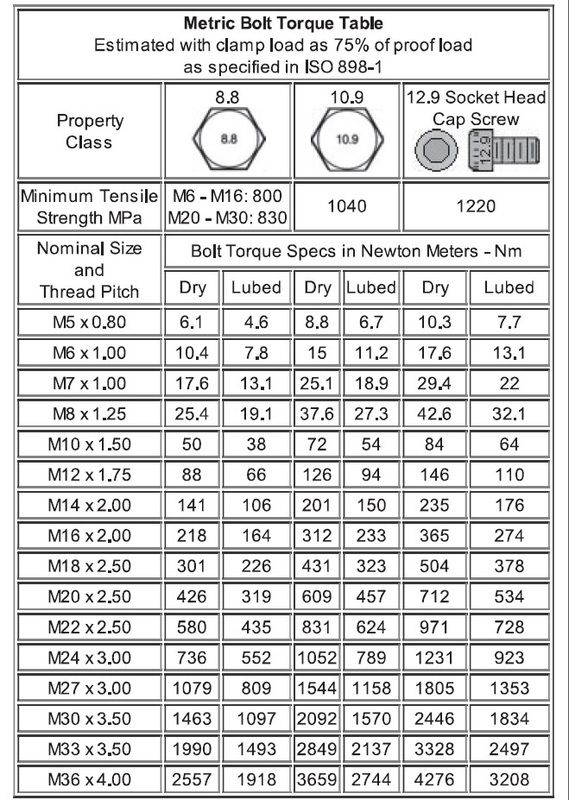

Wheel Bearing Torque Chart - Web and nuts that secure the wheel hub and tire. This procedure applies to steer, drive and trailer axle assemblies using conventional double nut or single nut systems on class 6, 7 and 8 trucks. Many torque wrenches only go to 150 lbs. [49] tighten the hub bearing nut by the following procedures. The torque speciication for this center axle nut is critical to performance and function of the wheel hub. Putting the proper torque on the center axle nut sets the preload for the bearing and keeps the bearing from separating while in operation. The wheel hub mounting bolt torque speciication also provides a secure it for the wheel hub and. You’ll need a torque wrench capable of the measuring the maximum torque specified. Web tighten the hub nut until the scale reads: Back off the adjusting nut one full turn or until it is loose. The wheel hub mounting bolt torque speciication also provides a secure it for the wheel hub and. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Sometimes this is 2oo lb. The torque speciication for this center axle nut is critical to performance and function. This refers only to torque specifications and bearing adjustment. Web putting the proper torque on the center axle nut sets the preload for the bearing and keeps the bearing from separating while in operation. [49] tighten the hub bearing nut by the following procedures. The wheel hub mounting bolt torque speciication also provides a secure it for the wheel hub. Web the service manual for your vehicle will have a detailed method of adjusting and correctly tightening your wheel bearings. The wheel hub mounting bolt torque speciication also provides a secure it for the wheel hub and. You’ll need a torque wrench capable of the measuring the maximum torque specified. Many torque wrenches only go to 150 lbs. Putting the. Web putting the proper torque on the center axle nut sets the preload for the bearing and keeps the bearing from separating while in operation. [49] tighten the hub bearing nut by the following procedures. The wheel hub mounting bolt torque speciication also provides a secure it for the wheel hub and. Many torque wrenches only go to 150 lbs.. This refers only to torque specifications and bearing adjustment. This procedure applies to steer, drive and trailer axle assemblies using conventional double nut or single nut systems on class 6, 7 and 8 trucks. Many torque wrenches only go to 150 lbs. Sometimes this is 2oo lb. The wheel hub mounting bolt torque speciication also provides a secure it for. [49] tighten the hub bearing nut by the following procedures. This refers only to torque specifications and bearing adjustment. Web the goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). This procedure applies to steer, drive and trailer axle assemblies using conventional double nut or single nut. Web and nuts that secure the wheel hub and tire. Web the service manual for your vehicle will have a detailed method of adjusting and correctly tightening your wheel bearings. Back off the inner (adjusting) nut the amount indicated in the chart below. The wheel hub mounting bolt torque speciication also provides a secure it for the wheel hub and.. The wheel hub mounting bolt torque speciication also provides a secure it for the wheel hub and. Putting the proper torque on the center axle nut sets the preload for the bearing and keeps the bearing from separating while in operation. Web the goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to. Web tighten the hub nut until the scale reads: The torque speciication for this center axle nut is critical to performance and function of the wheel hub. Web the service manual for your vehicle will have a detailed method of adjusting and correctly tightening your wheel bearings. Web the goal of this recommended procedure is to achieve a verifiable wheel. Web the goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to.127 mm). Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. The wheel hub mounting bolt torque speciication also provides a secure it. You’ll need a torque wrench capable of the measuring the maximum torque specified. Web tighten the hub nut until the scale reads: Web putting the proper torque on the center axle nut sets the preload for the bearing and keeps the bearing from separating while in operation. Most drive axle wheel hubs have a center axle nut that must be torqued down onto the axle shaft to a specific torque value. Many torque wrenches only go to 150 lbs. Web the service manual for your vehicle will have a detailed method of adjusting and correctly tightening your wheel bearings. The torque speciication for this center axle nut is critical to performance and function of the wheel hub. Putting the proper torque on the center axle nut sets the preload for the bearing and keeps the bearing from separating while in operation. This procedure applies to steer, drive and trailer axle assemblies using conventional double nut or single nut systems on class 6, 7 and 8 trucks. Back off the adjusting nut one full turn or until it is loose. Back off the inner (adjusting) nut the amount indicated in the chart below. [49] tighten the hub bearing nut by the following procedures. The wheel hub mounting bolt torque speciication also provides a secure it for the wheel hub and.

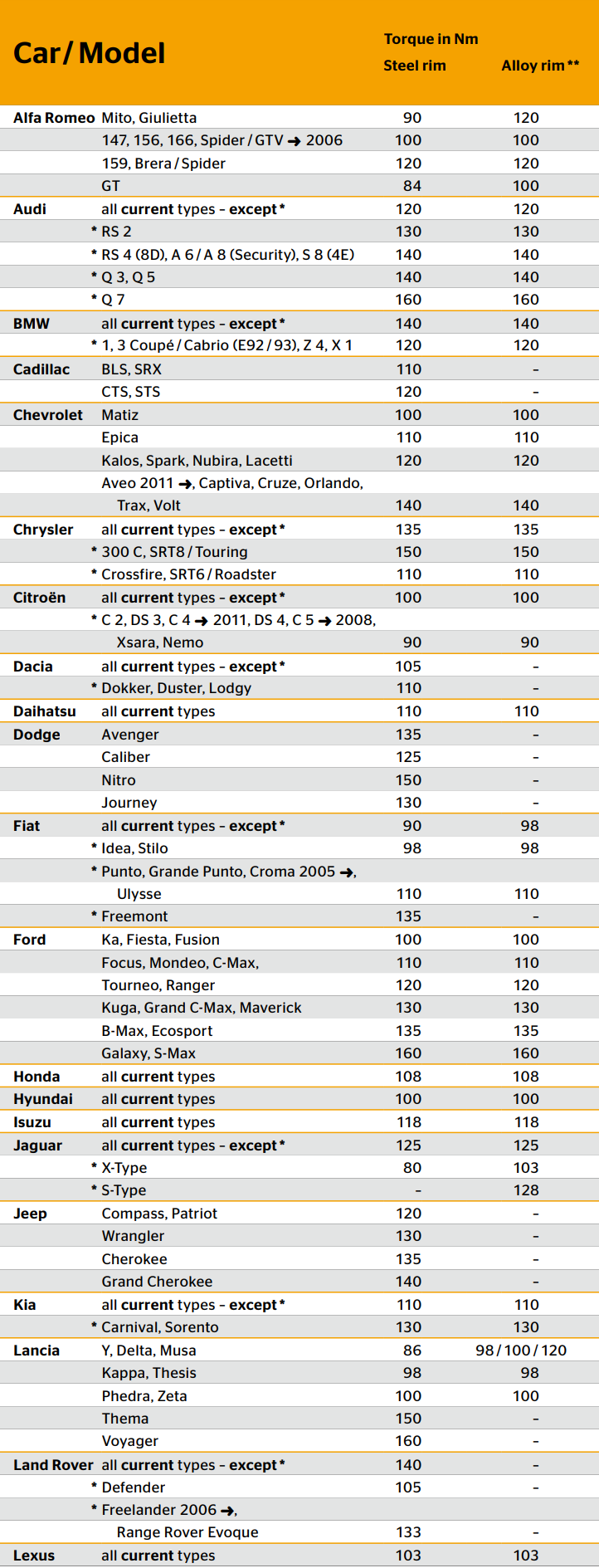

Wheel Torque Chart Settings

Torque Specifications Machine Service, Inc.

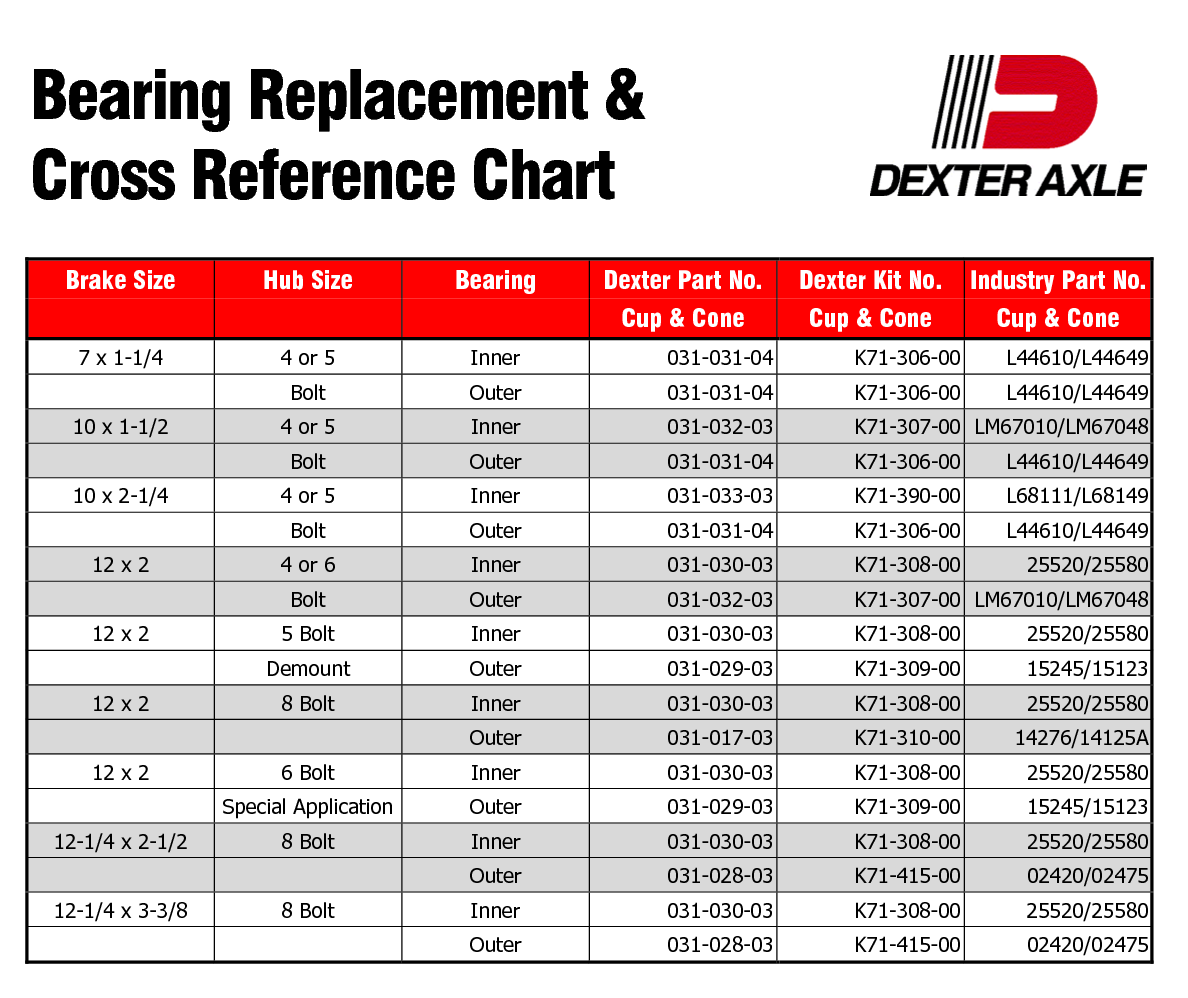

Trailer Wheel Bearing Maintenance Felling Trailers

Wheel Torque Chart The Wheel Warehouse

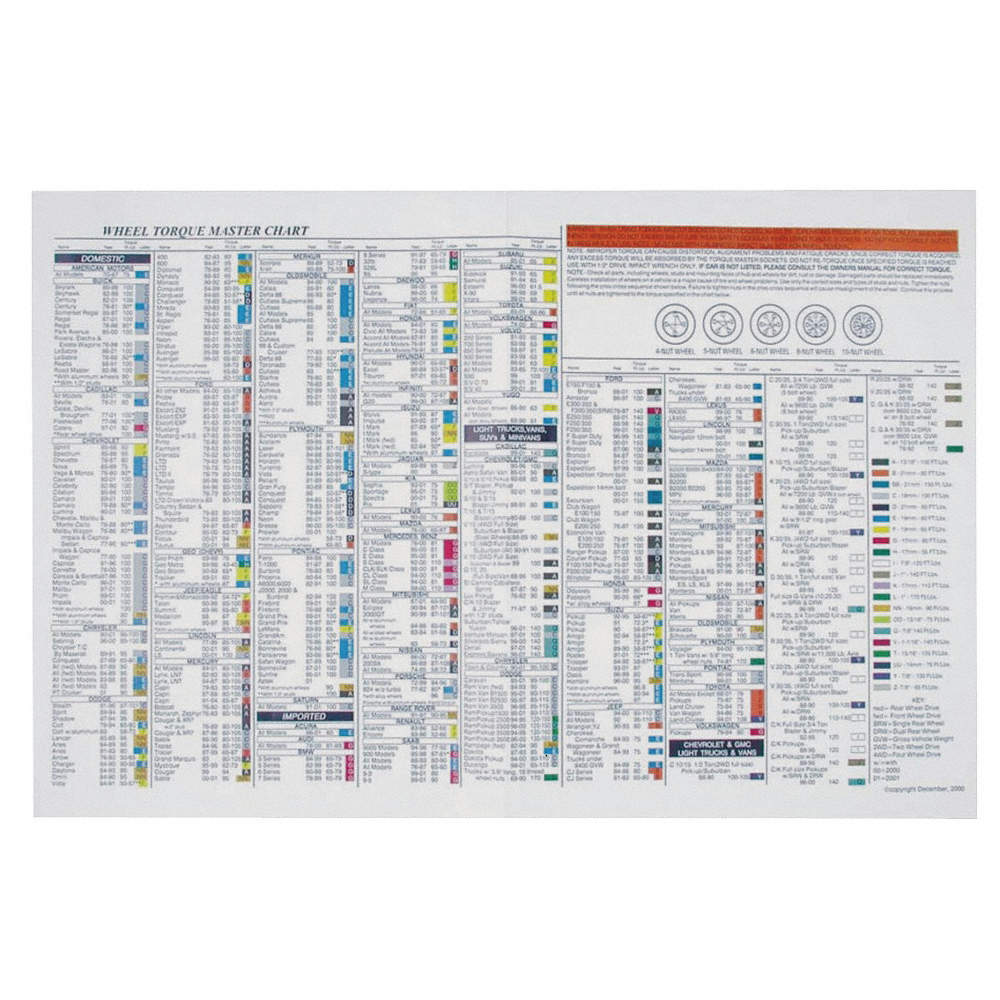

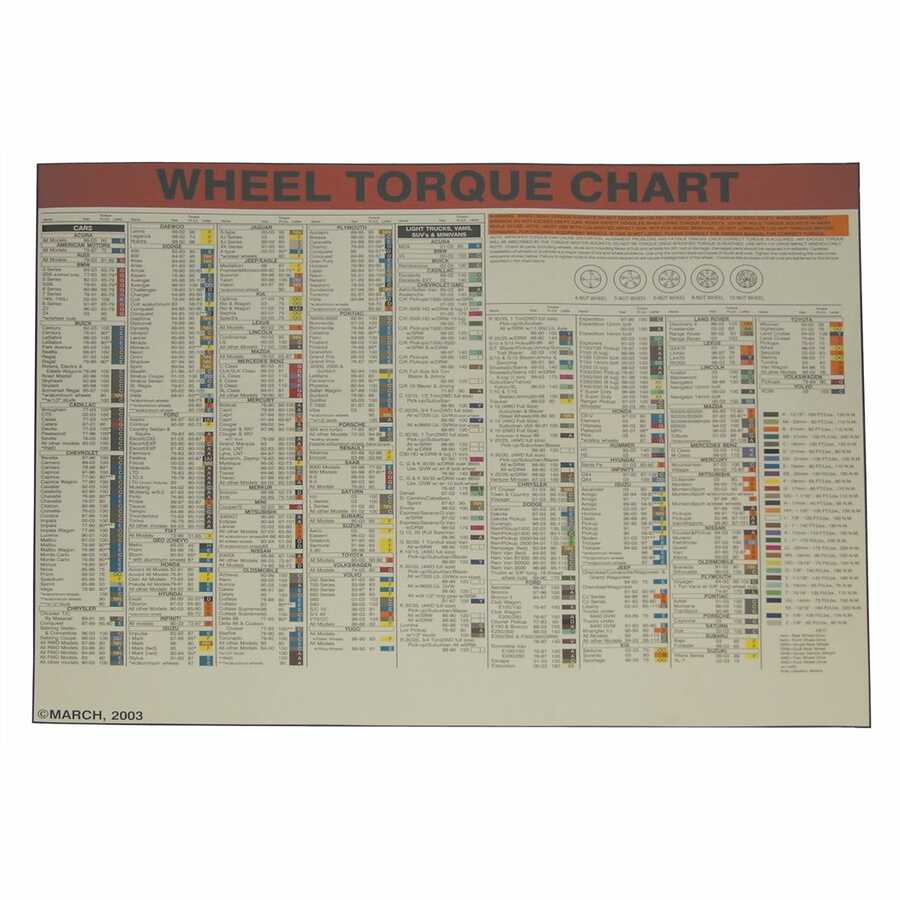

Torque Wall Chart Lock Technology LT1500LWC

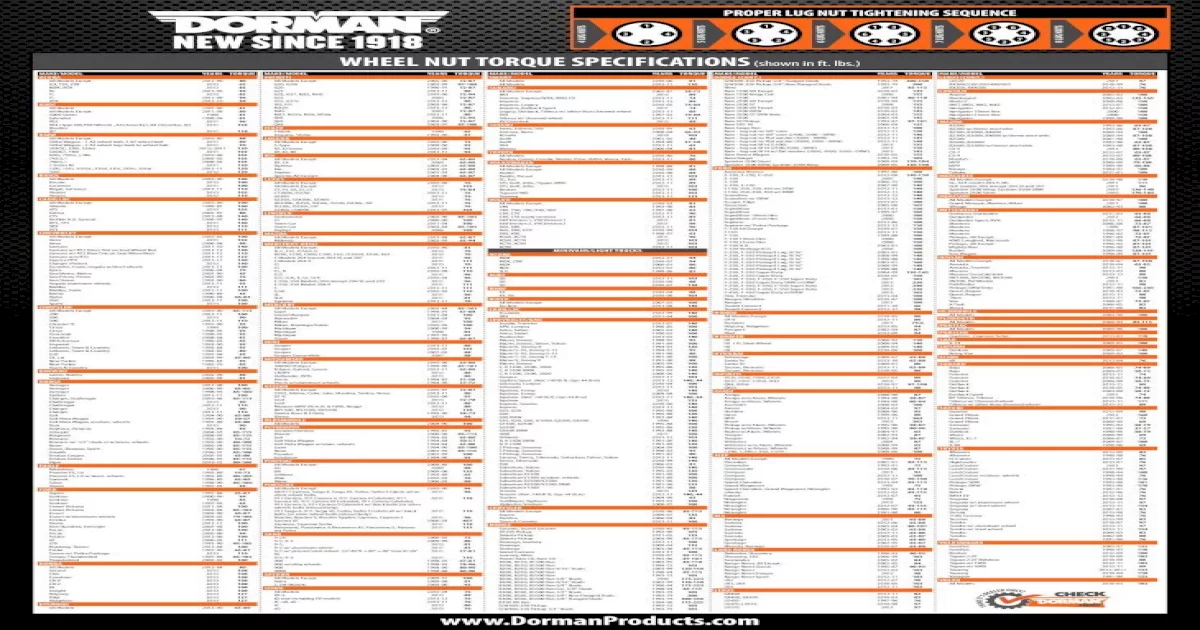

WHEEL NUT TORQUE SPECIFICATIONS (shown in ft. lbs.) .WHEEL NUT TORQUE

Rear Wheel Bearing Torque Spec Question Acura TSX Forum

Printable Automotive Wheel Torque Chart

Top Ten Wheel Bearing Torque Tips

Wheel Wheel Nut Torque Spec

This Refers Only To Torque Specifications And Bearing Adjustment.

Web The Goal Of This Recommended Procedure Is To Achieve A Verifiable Wheel Bearing End Play Of 0.001” To 0.005” (.025 Mm To.127 Mm).

Web And Nuts That Secure The Wheel Hub And Tire.

Sometimes This Is 2Oo Lb.

Related Post: