X Bar And R Chart

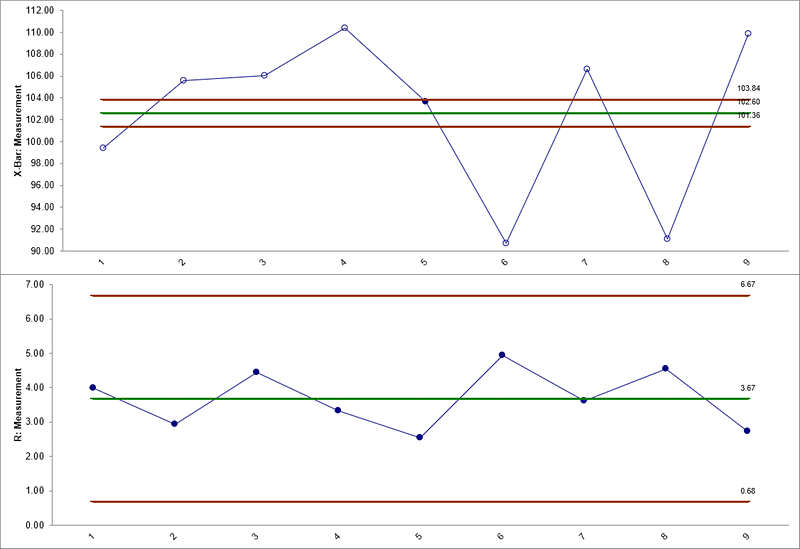

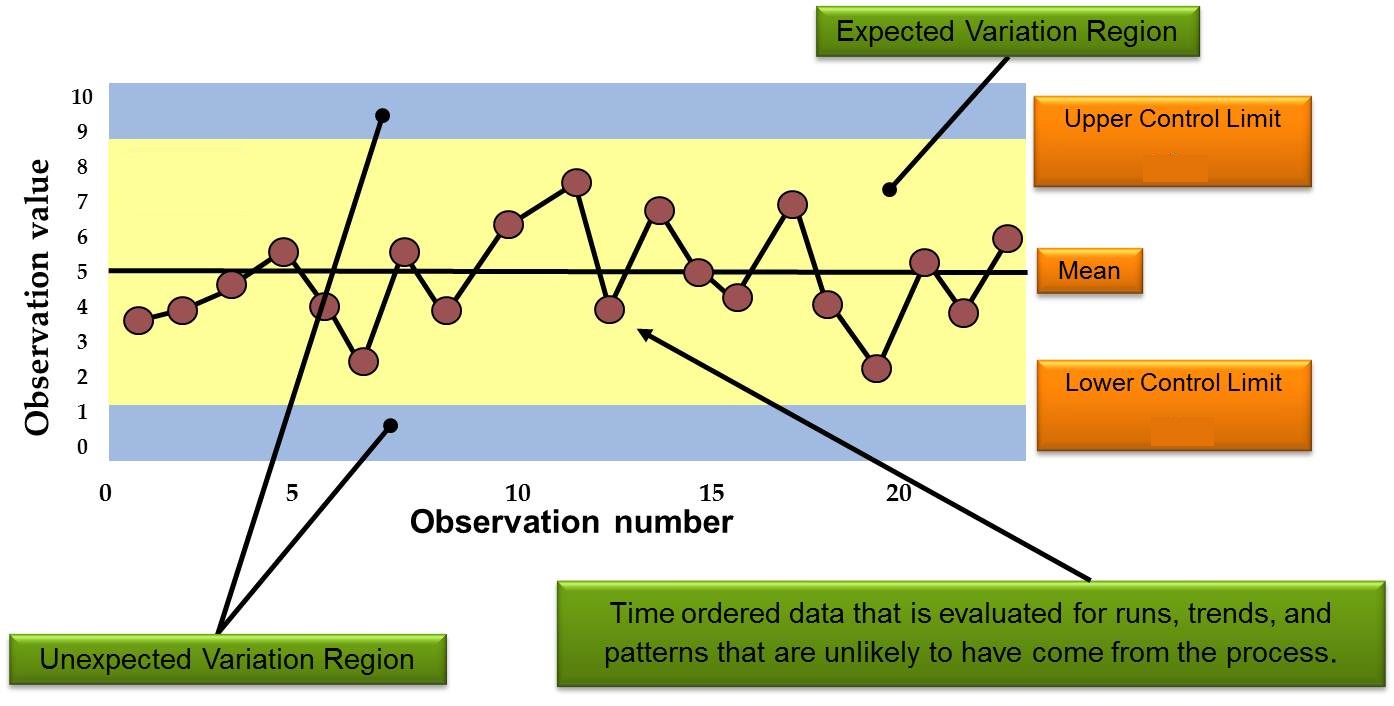

X Bar And R Chart - Please let me know if you find it helpful! 15k views 4 years ago excel for engineers: Identify which points failed each test. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Select “publications” to go to the spc knowledge base homepage. Web the x bar chart shows how the mean or average of the process changes over time and the r (or s) chart shows how the range or variance changes over time. These are used to monitor the effects of process improvement theories. The control limits on both chats are used to monitor the. Armed with this background we can now develop the \(\bar{x}\) and \(r\) control chart. They are a standardized chart for variables data and help determine if a particular process is predictable and stable. The upper specification limit (usl) is 108 inches. Web the mean of \(r\) is \(d_2 \sigma\), where the value of \(d_2\) is also a function of \(n\). Xbarr chart data usually looks like this: An xbar chart is a graphical representation of the average value of a data set over a period of time. Both charts’ control limits are used. In statistical process control (spc), the and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. Web how to interpret the x bar r control charts. Examine the xbar chart to. If your sample size is 1 or more than 10, you need to select different control charts. Both charts’ control limits are used to monitor the. The range (r) chart shows the variation within each variable (called subgroups). Identify which points failed each test. Web how to interpret the x bar r control charts. Web spc knowledge base. Please let me know if you find it helpful! Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. An estimator of \(\sigma\) is therefore \(r / d_2\). Web the x bar chart shows how the mean or average of the process changes over time and the r (or s) chart shows how. Here is some further information about the charts. Web the mean of \(r\) is \(d_2 \sigma\), where the value of \(d_2\) is also a function of \(n\). They are a standardized chart for variables data and help determine if a particular process is predictable and stable. The x bar chart controls limits that are derived from the r bar (average. Each operator fires the ball 3 times. Select “publications” to go to the spc knowledge base homepage. Identify which points failed each test. The range (r) chart shows the variation within each variable (called subgroups). An estimator of \(\sigma\) is therefore \(r / d_2\). Armed with this background we can now develop the \(\bar{x}\) and \(r\) control chart. Web the x bar chart shows how the mean or average of the process changes over time and the r (or s) chart shows how the range or variance changes over time. Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. An. The control limits on both chats are used to monitor the. The upper specification limit (usl) is 108 inches. Web spc knowledge base. Select “publications” to go to the spc knowledge base homepage. If your sample size is 1 or more than 10, you need to select different control charts. The x bar chart controls limits that are derived from the r bar (average range) values. An r chart is a type of statistical chart used to monitor the quality of data over time. Examine the r chart to determine whether the process variation is in control. Identify which points failed each test. 15k views 4 years ago excel for. Xbarr chart data usually looks like this: They are a standardized chart for variables data and help determine if a particular process is predictable and stable. The control limits on both chats are used to monitor the. 15k views 4 years ago excel for engineers: Examine the xbar chart to determine whether the process mean is in control. The x bar chart controls limits that are derived from the r bar (average range) values. If the r chart’s values are out of control, the x bar chart control limits are inaccurate. Web spc knowledge base. Web how to interpret the x bar r control charts. Example of an xbarr chart (average and range chart) created by qi macros. Examine the xbar chart to determine whether the process mean is in control. Both charts’ control limits are used to monitor the. The range (r) chart shows the variation within each variable (called subgroups). If your sample size is 1 or more than 10, you need to select different control charts. These are used to monitor the effects of process improvement theories. Select “publications” to go to the spc knowledge base homepage. X bar and r charts are recommended for subgroup sizes of 10 or less. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Web the mean of \(r\) is \(d_2 \sigma\), where the value of \(d_2\) is also a function of \(n\). Examine the r chart to determine whether the process variation is in control. They are a standardized chart for variables data and help determine if a particular process is predictable and stable.

Statistical Process Control (SPC) CQE Academy

How to Create an XbarR Chart in Minitab 18 ToughNickel

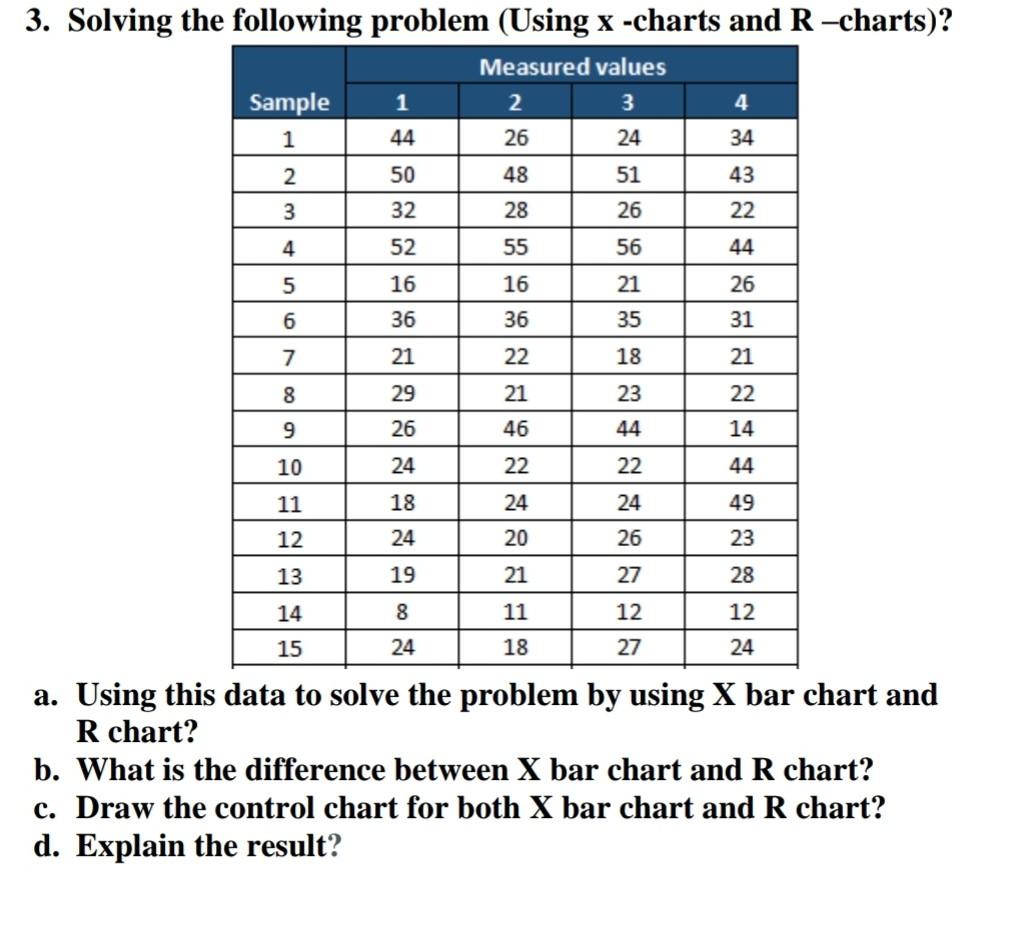

Solved Solving the following problem ( Using x charts and R

Xbar and R Chart Formula and Constants The Definitive Guide

IMRR/S Control Charts

Control Limits for xbar r chart show out of control conditions

After discussing the several aspects and uses ofXbar and R Charts, we

Difference Between XBar and RChart and How They Are Used ROP

X Bar & R chart Tool tip JMP User Community

Total 48+ imagen x bar and r chart Expoproveedorindustrial.mx

An Xbar Chart Is A Graphical Representation Of The Average Value Of A Data Set Over A Period Of Time.

The Size Of The Subgroups Is Also Very Important, It Needs To Be Between 2 And 10.

Xbarr Chart Data Usually Looks Like This:

In Statistical Process Control (Spc), The And R Chart Is A Type Of Scheme, Popularly Known As Control Chart, Used To Monitor The Mean And Range Of A Normally Distributed Variables Simultaneously, When Samples Are Collected At Regular Intervals From A Business Or Industrial Process.

Related Post: