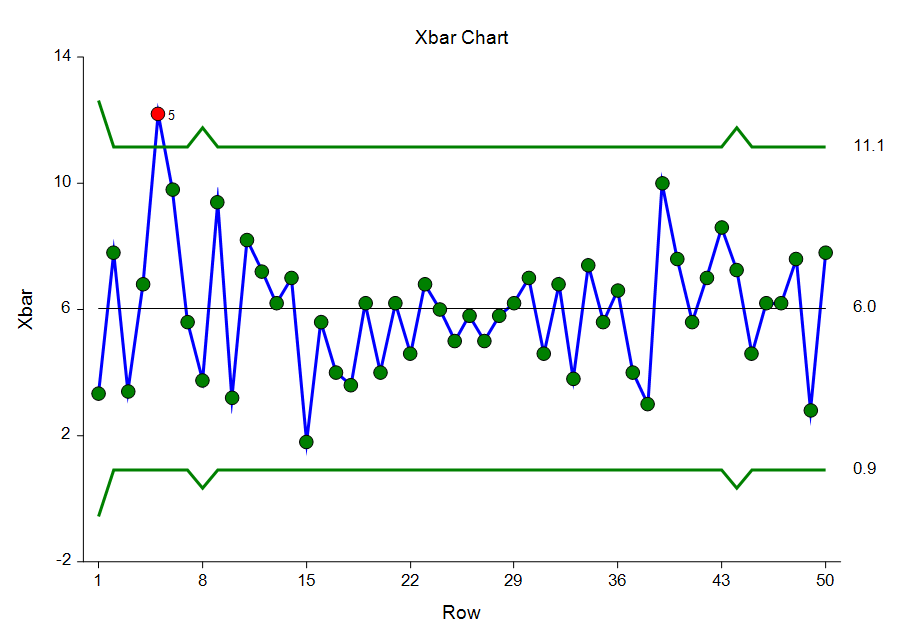

Xbar Chart

Xbar Chart - Here is some further information about the charts. Web result the xbar chart plots the average of the measurements within each subgroup. The mean or average change in a process over time from subgroup values. This monitors the spread of the process over time. The range of the process over time from subgroup values. It is particularly helpful in identifying any shifts or trends in the process, allowing for timely interventions to maintain quality. The lesson will include practice creating. The chart consists of two components: If unspecified, the process mean is the weighted mean of the subgroup. Web result the right way to create xbar & r charts using ms excel! The center line is the process mean. The lesson will include practice creating. Select the method or formula of your choice. Web result use xbar chart to monitor the mean of your process when you have continuous data in subgroups. The range of the process over time from subgroup values. Explain the purpose of using an xbar chart in. It is particularly helpful in identifying any shifts or trends in the process, allowing for timely interventions to maintain quality. A(3) can be found in the following table: Select the method or formula of your choice. The control limits on the x bar consider the sample’s mean and center. Once mastered, it provides data to leaders on changes they should make as well as measuring the success of changes put into place. Select the method or formula of your choice. The lesson describes how to create this control chart in both microsoft excel and using minitab. It is particularly helpful in identifying any shifts or trends in the process,. The mean or average change in the process over time from subgroup values. Find the ucl and lcl using the following equations: For example, a plastics manufacturer wants to determine whether the production process for a new. The center line is the average of all subgroup averages. Learn more about minitab statistical software. The center line is the process mean. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. The chart consists of two components: Web result xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data.. If the process is in control, the points vary randomly around the center line, and the process exhibits only. Web result the xbar chart plots the average of the measurements within each subgroup. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Find the mean of. The standard deviation of the process over time from subgroups values. Learn more about minitab statistical software. Use x bar r control charts when: If the process is in control, the points vary randomly around the center line, and the process exhibits only. The control limits on the xbar chart, which are set at a distance of 3 standard deviations. The control limits on the xbar chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of variation that is expected in the subgroup averages. Web result the plotted points on an xbar chart represent the averages of the measurements within each subgroup. Explain the purpose of using an xbar. Here is some further information about the charts. Learn more about minitab statistical software. The chart consists of two components: Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. The center line is the process mean. Each point on the chart represents the value of a subgroup mean. Here is some further information about the charts. Web result steps in constructing the xbar chart. The lesson will include practice creating. The center line is the average of all subgroup averages. Web result the plotted points on an xbar chart represent the averages of the measurements within each subgroup. Number of samples = sample size = create table. This monitors the spread of the process over time. Find the mean of each subgroup xbar (1), xbar (2), xbar (3)… xbar (k) and the grand mean of all subgroups using: Find the ucl and lcl using the following equations: The control limits on both chats are used to monitor the mean and variation of the process going forward. Web result median control charts, also known as x̃ control charts, fill a crucial gap between individual charts and averages charts (xbar charts). Explain the purpose of using an xbar chart in. Web result x bar chart: Web result use xbar chart to monitor the mean of your process when you have continuous data in subgroups. The chart consists of two components: Each plotted point, , represents the mean of the observations for subgroup,. This monitors the process standard deviation (as approximated by the sample moving. Use x bar r control charts when: More about this xbar chart maker. The center line is the average of all subgroup averages.

How To Plot Xbar And RBar Chart In Excel hopdeneed

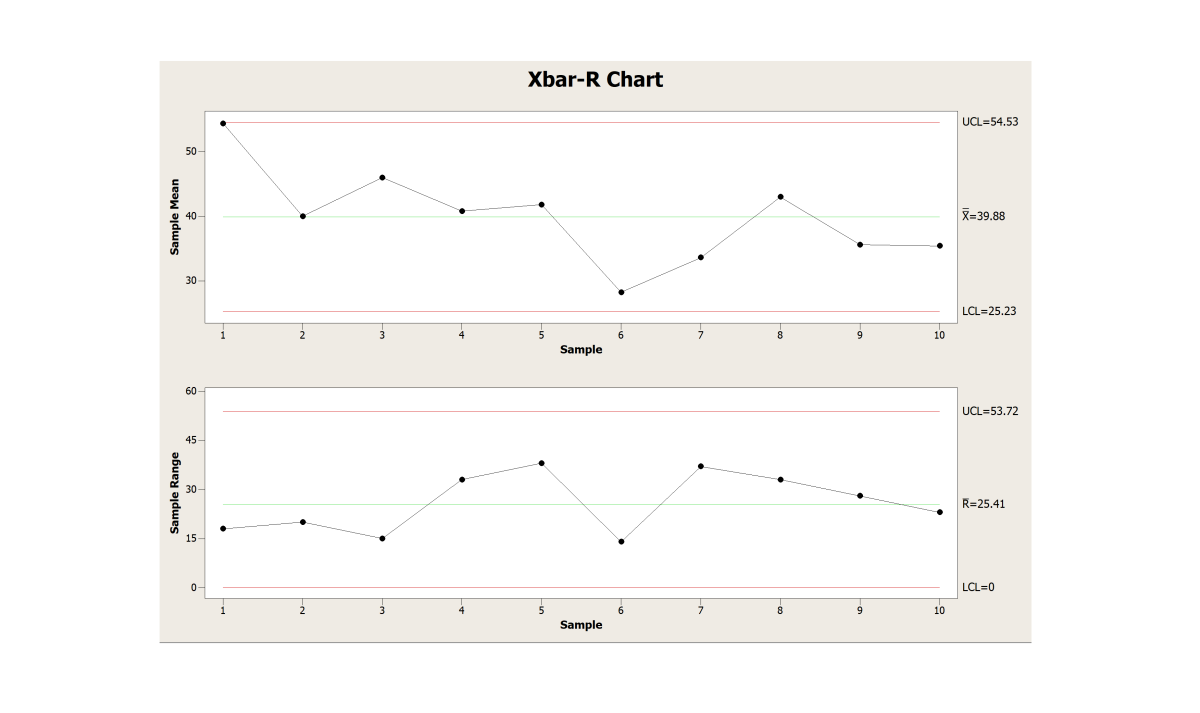

XbarR chart showed for VOB beforeSpecial causes of variation

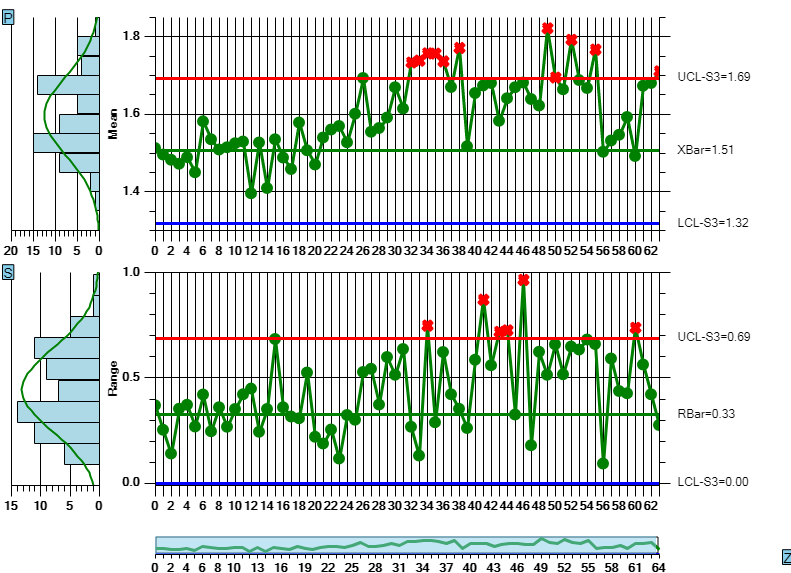

NCSS Quality Control NCSS Statistical Software

How to Create an XbarR Chart in Minitab 18 ToughNickel

xbar chart YouTube

Control Limits for xbar r chart show out of control conditions

Solved Interpret the XbarR chart below When do we use Xbar

When to use an Xbar R Chart versus Xbar S Chart

XBarR Chart SPC Charts Online

Xbar S Chart with Minitab Lean Sigma Corporation

Web Result The Right Way To Create Xbar & R Charts Using Ms Excel!

Web Result The Xbar Chart Plots The Average Of The Measurements Within Each Subgroup.

The Lesson Will Include Practice Creating.

The Lesson Describes How To Create This Control Chart In Both Microsoft Excel And Using Minitab.

Related Post: