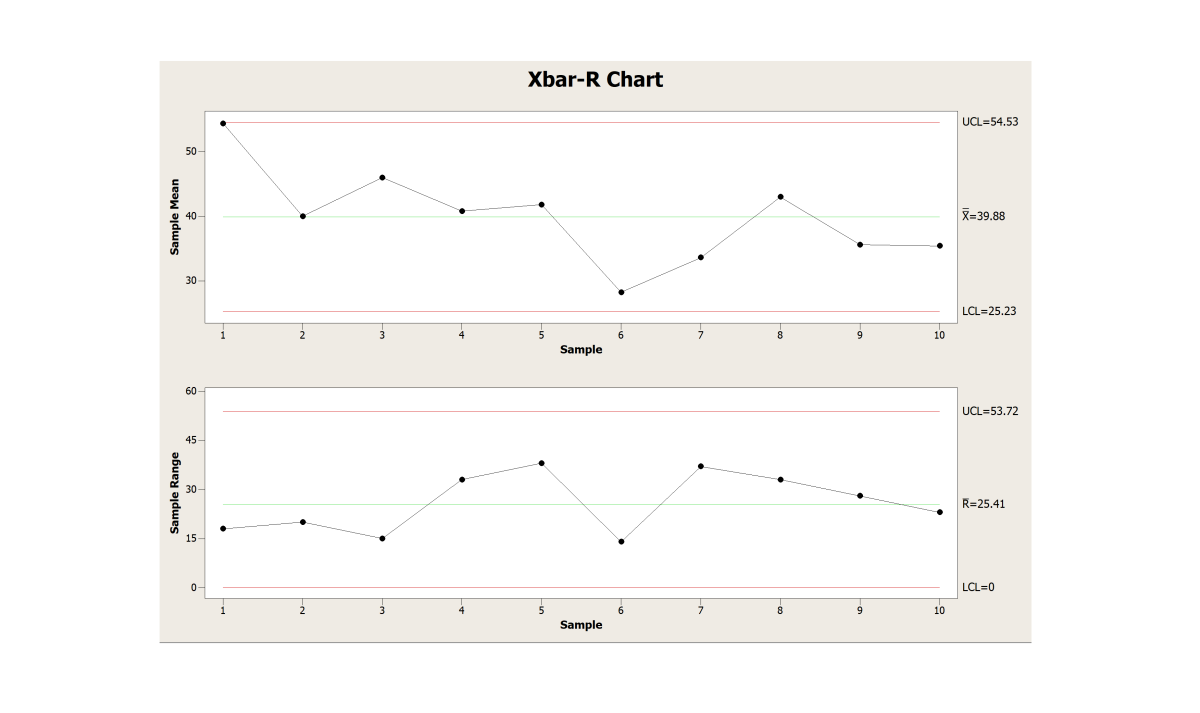

Xbar R Chart

Xbar R Chart - Web an xbar chart is a graphical representation of the average value of a data set over a period of time. The center line is the average of all subgroup averages. The engineer measures five camshafts from each machine during each shift. Learn more about minitab statistical software. It is actually two plots to monitor the process mean and the process variation over time and is an example of statistical process control. Web x bar r chart is used to monitor the process performance of continuous data. Please let me know if you find it helpful! The lesson describes how to create this control chart in both microsoft excel and using minitab. The r chart plots the difference between the highest and lowest values within a subgroup as a data point. Three machines manufacture camshafts for three shifts each day. This is one of the most commonly encountered control chart variants, and leverages two different views: The xbar r chart is a control chart for continuous data with a constant subgroup size between two and ten. Three machines manufacture camshafts for three shifts each day. This lesson explains how the data is recorded and interpreted on the chart. Select “publications”. Web an xbar chart is a graphical representation of the average value of a data set over a period of time. Here is some further information about the charts. 15k views 4 years ago excel for engineers: A quality engineer at an automotive parts plant monitors the lengths of camshafts. For the purposes of this publication, the chart to use. Please let me know if you find it helpful! This is one of the most commonly encountered control chart variants, and leverages two different views: When discussing spc, this is always the example. A simulation was developed to help do this. Here is some further information about the charts. Web the right way to create xbar & r charts using ms excel! A quality engineer at an automotive parts plant monitors the lengths of camshafts. Select “publications” to go to the spc knowledge base homepage. It is used to detect any variability in the process mean and range of data collected over time. This is one of the most. Web x bar r chart is used to monitor the process performance of continuous data. Web the right way to create xbar & r charts using ms excel! The engineer measures five camshafts from each machine during each shift. For the purposes of this publication, the chart to use is the one that gives you the best estimate of the. Web the xbar chart plots the average of the measurements within each subgroup. The engineer measures five camshafts from each machine during each shift. The xbar r chart is a control chart for continuous data with a constant subgroup size between two and ten. It's used for variable data when the data is readily available. An r chart is a. The lesson describes how to create this control chart in both microsoft excel and using minitab. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a. Web. The lesson describes how to create this control chart in both microsoft excel and using minitab. The chart consists of two components: It's used for variable data when the data is readily available. A quality engineer at an automotive parts plant monitors the lengths of camshafts. The control limits on the xbar chart, which are set at a distance of. The control limits on the xbar chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of variation that is expected in the subgroup averages. The engineer measures five camshafts from each machine during each shift. Web xbar r charts are often used collectively to plot the process mean (xbar). This lesson explains how the data is recorded and interpreted on the chart. It is used to detect any variability in the process mean and range of data collected over time. This is one of the most commonly encountered control chart variants, and leverages two different views: 15k views 4 years ago excel for engineers: It's used for variable data. Web x bar r chart is used to monitor the process performance of continuous data. Web the xbar chart plots the average of the measurements within each subgroup. It is actually two plots to monitor the process mean and the process variation over time and is an example of statistical process control. The r chart plots the difference between the highest and lowest values within a subgroup as a data point. 15k views 4 years ago excel for engineers: The xbar chart plots the average of a subgroup as a data point. This lesson explains how the data is recorded and interpreted on the chart. Three machines manufacture camshafts for three shifts each day. Learn more about minitab statistical software. It's used for variable data when the data is readily available. When discussing spc, this is always the example. The engineer measures five camshafts from each machine during each shift. You can also use them to collect data from subgroups at set time periods. Select “publications” to go to the spc knowledge base homepage. An r chart is a type of statistical chart. A simulation was developed to help do this.

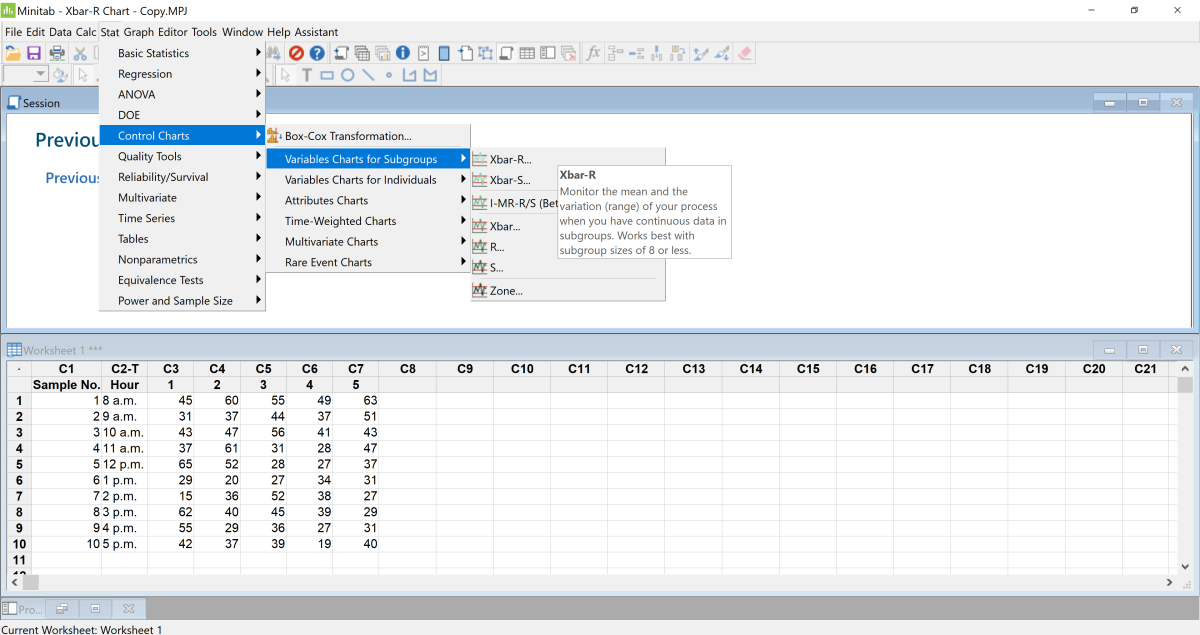

How to Create an XbarR Chart in Minitab 18 ToughNickel

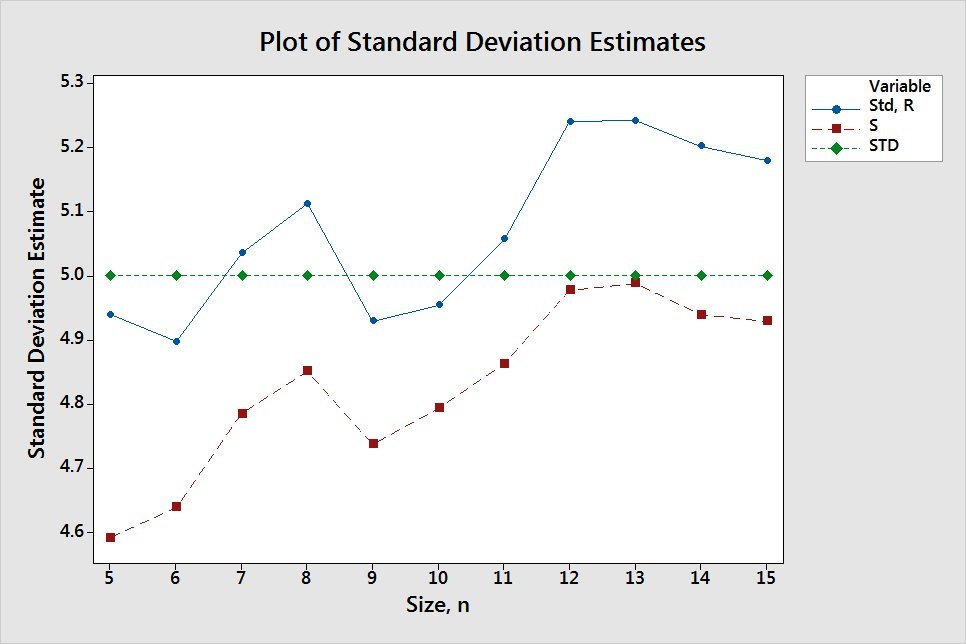

Xbar and R Chart Formula and Constants The Definitive Guide

What Are Control Limits On A Chart Best Picture Of Chart

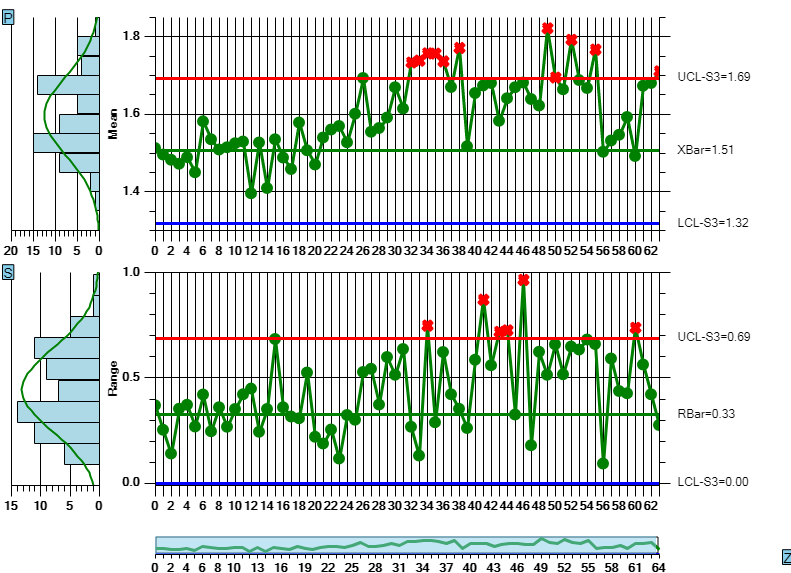

XbarR chart showed for VOB beforeSpecial causes of variation

How to Create an XbarR Chart in Minitab 18 ToughNickel

Control Limits for Individual Sample Yields limits that differ from

xbar r chart YouTube

XBarR Chart SPC Charts Online

How To Plot Xbar And RBar Chart In Excel hopdeneed

Xbar And R Chart Example

The Center Line Is The Average Of All Subgroup Averages.

A Quality Engineer At An Automotive Parts Plant Monitors The Lengths Of Camshafts.

Use This Control Chart To Monitor Process Stability Over Time So That You Can Identify And Correct Instabilities In A Process.

The Xbar R Chart Is A Control Chart For Continuous Data With A Constant Subgroup Size Between Two And Ten.

Related Post: