Keensert Drill Chart

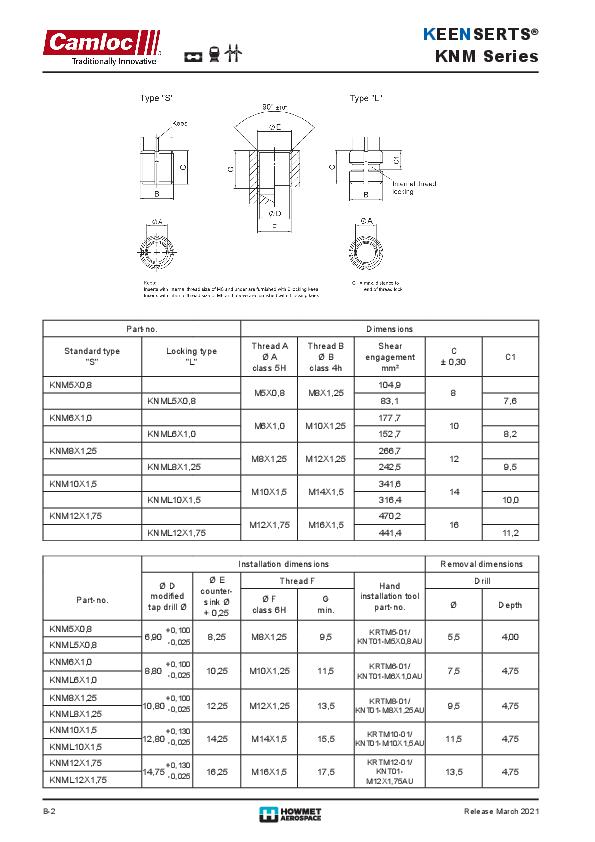

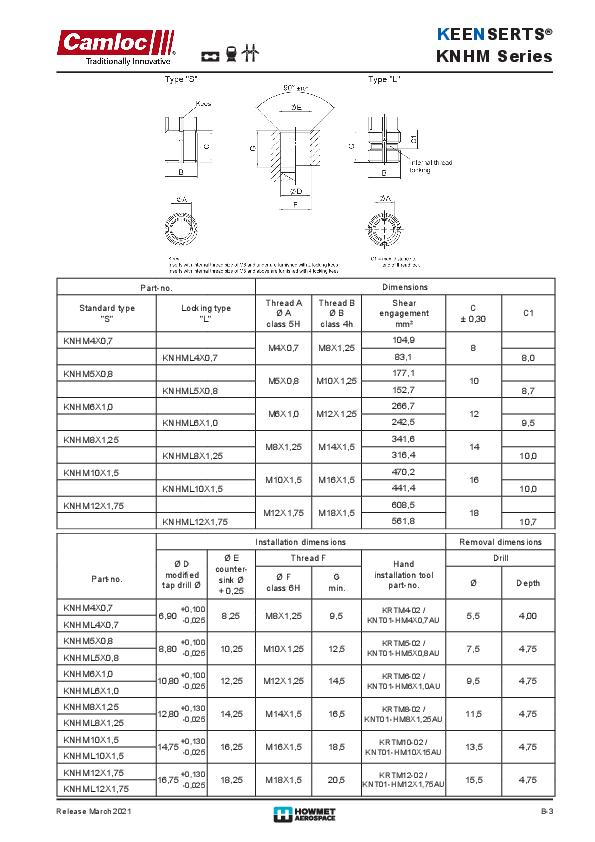

Keensert Drill Chart - Carr lane provides engineers with valuable resources. Web camloc® keenserts® provide high strength joints in low strength materials. Camloc keenserts ® can be used to give increased thread strength in low strength materials such as alloys. Key locking threaded inserts are also known as key inserts, keyserts, or keenserts. Screw in the insert until slightly below surface. Web camloc keenserts ® solid inserts overview. See charts for proper size and depth. They are available in a wide range of metric and imperial thread dimensions for numerous applications. Web drill out old threads with a standard drill. Apply a chamfer if required. Designed to repair damaged threads or for use in original equipment, keyserts®and keenserts®provide easy installation and versatility. Web camloc® keenserts® provide high strength joints in low strength materials. Web inserts with an id thread 5/16 and above have four locking keys, smaller sizes have two. Dfars with full certs are available. Drill the hole or drill out the old thread. Keenserts provide a strong, permanent thread in a weaker parent material. Screw in the insert until slightly below surface. See pdf document in 'download' window for available sizes and installation instructions. Drill is oversized see charts for proper dimensions. Apply a chamfer if required. Drill the hole or drill out the old thread with a standard drill. Apply a chamfer if required. Our products are dfar compliant with coc and full certifications available upon request. Available in inch and metric thread sizes, the stainless steel solid bushing configuration of the keenserts® guarantees the quality of the internal thread before installation. Keenserts provide a strong,. Af164 keysert horz.qxd 6/6/05 2:46 pm page 1 The second number (0.7) is the pitch which corresponds to the distance between two adjacent threads in millimeters. Carr lane provides engineers with valuable resources. M2 x 0.40 metric series: Typical applications are transmission housings, electronic equipment and suspension units. The keensert installation data chart lists a recommended minimum drill diameter and depth for the insert removal drilled hole. M2 x 0.40 metric series: Drive keys down with several hammer taps on the proper Key locking threaded inserts are also known as key inserts, keyserts, or keenserts. Web drill out old threads with a standard drill. Designed to repair damaged threads or for use in original equipment, keyserts®and keenserts®provide easy installation and versatility. Key locking threaded inserts are also known as key inserts, keyserts, or keenserts. 1 2 3 4 5 » Drill is oversize — see charts for proper dimensions. Typical applications are transmission housings, electronic equipment and suspension units. Drill is oversize — see charts for proper dimensions. They are available in a wide range of metric and imperial thread dimensions for numerous applications. Web ø d modified tap drill ø inch. Web knhxhl420j imperial series keensert. Carr lane provides engineers with valuable resources. Many popular sizes can ship within 24 hours. See charts for proper size and depth. Hole preparation tap drill size 0.453. Available in inch and metric thread sizes, the stainless steel solid bushing configuration of the keenserts® guarantees the quality of the internal thread before installation. Drill the hole or drill out the old thread with a standard drill. Key inserts are often used to reinforce tapped holes in aluminum tooling plates. We stock a huge inventory. Screw in the insert until slightly below surface. Web camloc® keenserts® provide high strength joints in low strength materials. Web keenserts ® hand tools knt. 1 2 3 4 5 » Key inserts are often used to reinforce tapped holes in aluminum tooling plates. Select a part number from a table below for technical specifications. Our products are dfar compliant with coc and full certifications available upon request. Drive keys down with several hammer taps on the proper In stock and ready to ship. Standard drill to specified depth (refer to charts for proper dimensions). Typical applications are transmission housings, electronic equipment and suspension units. 1 2 3 4 5 » Dfars with full certs are available. Tap the new thread with a standard tap. The second number (0.7) is the pitch which corresponds to the distance between two adjacent threads in millimeters. They are available in a wide range of metric and imperial thread dimensions for numerous applications. See charts for proper size and depth. Apply a chamfer if required. Web drill out old threads with a standard drill. Web light duty and heavy duty keensert® inserts are available in a range of thread sizes. See pdf document in 'download' window for available sizes and installation instructions. Screw in insert with fingers or installation tool. Grade but can be supplied in milspec. Drill the hole or drill out the old thread with a standard drill.

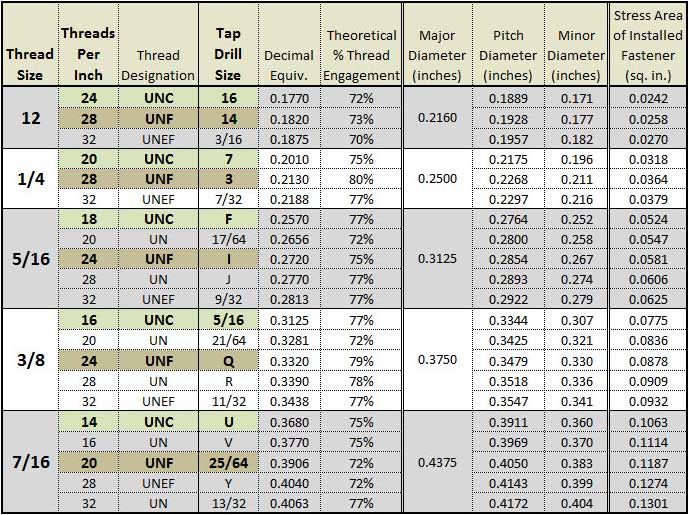

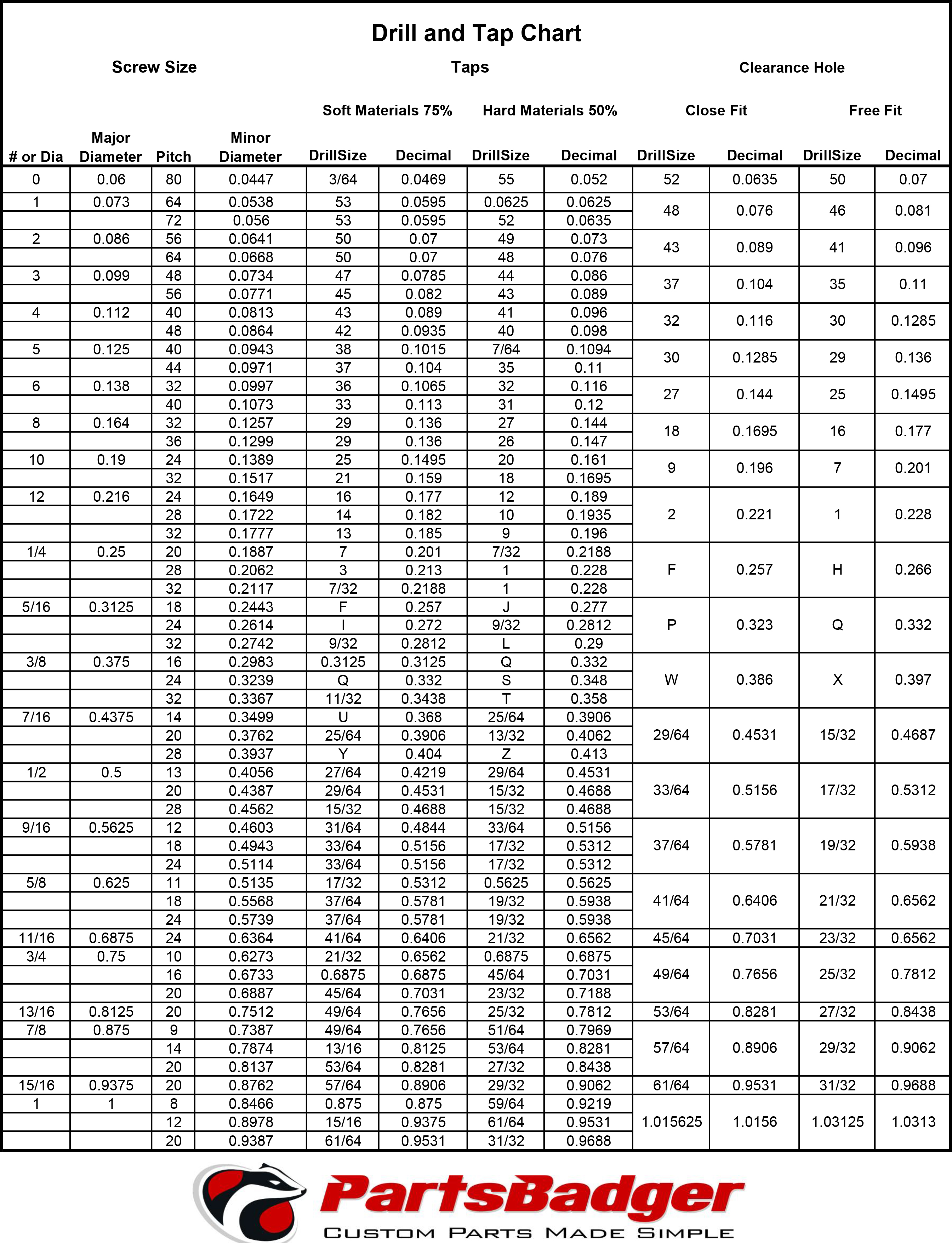

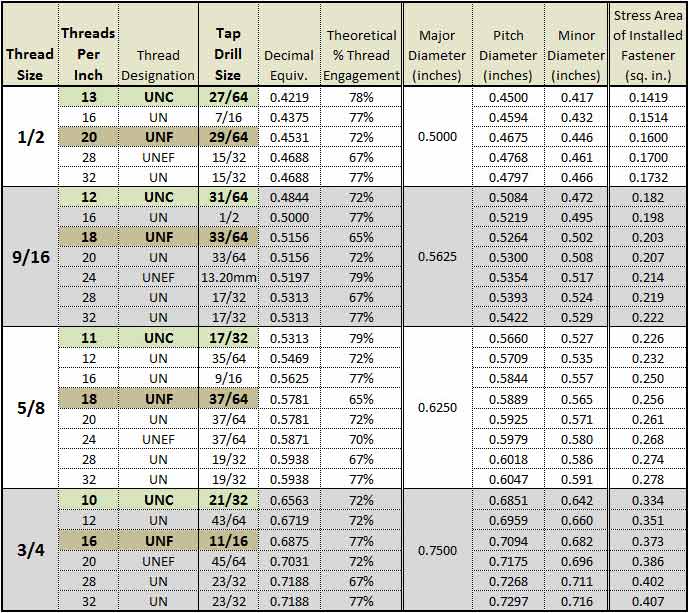

Tap Drill Chart

Repair Guides Engine Mechanical Specification Charts

Tap And Drill Chart Printable Printable Word Searches

Keensert Drill And Tap Chart Lamer

Tap Drill Chart

Keensert Solid Inserts

Keensert Drill And Tap Chart Labb by AG

Keensert Drill And Tap Chart Lamer

Gallery of cogent drill sizes for helicoil chart pipe tap drill chart

Keensert Solid Inserts

Key Inserts Are Often Used To Reinforce Tapped Holes In Aluminum Tooling Plates.

Many Popular Sizes Can Ship Within 24 Hours.

Camloc Keenserts ® Can Be Used To Give Increased Thread Strength In Low Strength Materials Such As Alloys.

Web Drill Out Old Threads With A Standard Drill.

Related Post: