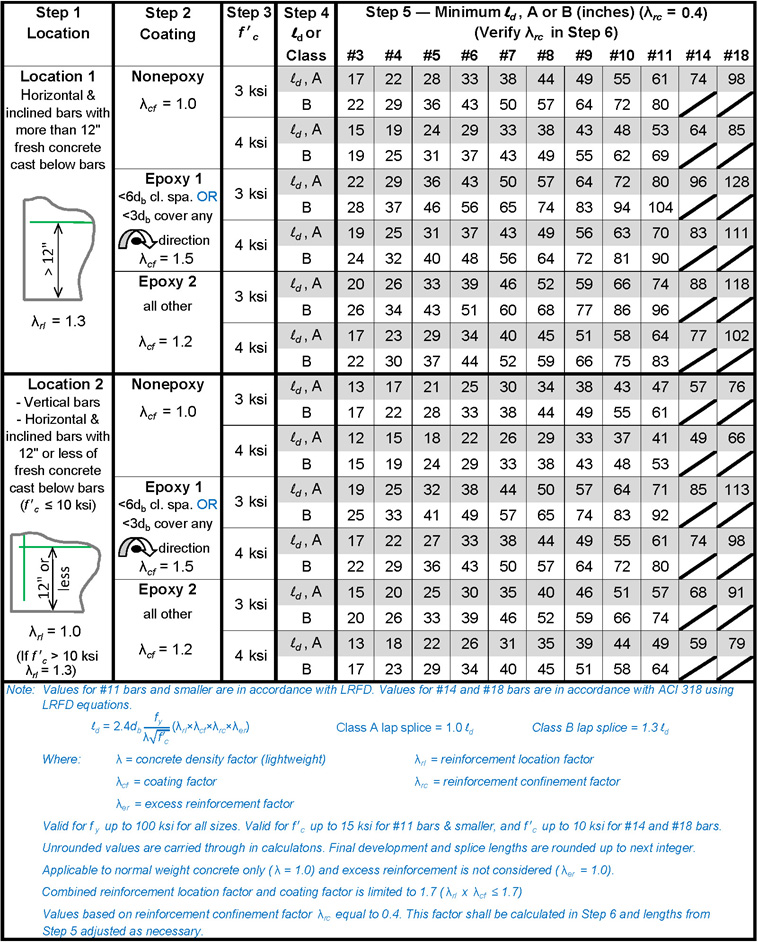

Lap Splice Length For Rebar Chart

Lap Splice Length For Rebar Chart - In which case, the required lap splice length is 1.3 x development length but not less than 12 inches. Refer to images to the right for further information. For astm a615 grade 60 bar: That is determined by the engineering load. Refer to your reinforcing chart for your particular project. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Compression lap splice length is governed by several conditions as follows: Web in the most common cases, the tension lap is considered class b. Web straight development and class b splice lengths shown in above tables are. Web a lap splice is the most common method of creating a single structural entity from two rebar segments. From a structural point of view, the most critical aspect of a lap splice is the overlap length. Type 1 mechanical splice shall develop in tension and compression as required at least 125% of the specified yield of the bar. In which case, the required lap splice length is 1.3 x development length but not less than 12 inches. Web. Compression lap splice length is governed by several conditions as follows: When reinforcement bars of different sizes are bundled as. Web wiring requirements for lap splicing rebar; So simply put, development is rebar to concrete, splice is rebar to rebar. Concrete strength steel grade rebar type splice length; [ for fy > 60,000 psi] the minimum lap length for compression bars must be 12inches. Type 1 mechanical splice shall develop in tension and compression as required at least 125% of the specified yield of the bar. Number of bar diameters (using bar size) 10: Web in the most common cases, the tension lap is considered class b. Web. Web the minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: The lap length for compression lap splice is calculated as per aci 12.16.1 as; Divide by 1.3 for class a splices or for developent lengths of deformed bars in tension. So simply put, development is rebar to concrete, splice is rebar to rebar.. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. They are dependent upon different factors. Web wiring requirements for lap splicing rebar; Ls = 0.0005fy (d) ; This is often a need for new construction with a preferred construction sequence. Extension of existing reinforced concrete structures. But not less than 12 inches (305 mm). They are dependent upon different factors. Web millimetres of lap related to number of bar diameters: Web straight development and class b splice lengths shown in above tables are. The lap length for compression lap splice is calculated as per aci 12.16.1 as; Web tables 4a and 4b present minimum lap splice lengths for reinforcement placed in the center of the wall, for f’ m = 1,500 and 2,000 psi (10.3 and 13.7 mpa), respectively. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create. Tables 4c and 4d present minimum lap splice lengths for reinforcement offset in the wall, for f’ m = 1,500 and 2,000 psi (10.3 and 13.7 mpa), respectively. As an alternative to lap splicing, reinforcing bars can be spliced by welding. Web lap splice lengths for f'c 12.3 and 12.16, respectively. To stay with the codes, we use this chart. Web splice lengths are rounded up to the nearest inch. Refer to your reinforcing chart for your particular project. Web the minimum length of lap splices for reinforcing bars in tension or compression, ld, shall be: Web millimetres of lap related to number of bar diameters: Fs = computed stress in reinforcement due to design loads, psi (mpa). Lengths are in inches.= 3,000 psi to 5,000 psi notes: When reinforcement bars of different sizes are bundled as. Select wire/bar size to be developed/spliced: For compression development lengths, if. Refer to your reinforcing chart for your particular project. Refer to your reinforcing chart for your particular project. Type 1 mechanical splice shall develop in tension and compression as required at least 125% of the specified yield of the bar. That is determined by the engineering load. Lengths are in inches.= 3,000 psi to 5,000 psi notes: Web the length of a lap splice varies with concrete strength, type of concrete, the yield strength (grade) of the reinforcing bars, bar size, bar spacing, concrete cover, and the amount of ties or stirrups. Web it doesn’t mean a size minimum; Extension of existing reinforced concrete structures. Web millimetres of lap related to number of bar diameters: Web tables 4a and 4b present minimum lap splice lengths for reinforcement placed in the center of the wall, for f’ m = 1,500 and 2,000 psi (10.3 and 13.7 mpa), respectively. Ls = 0.0005fy (d) ; Divide by 1.3 for class a splices or for developent lengths of deformed bars in tension. Web select either lap splice or development length. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Compression lap splice length is governed by several conditions as follows: [ for fy > 60,000 psi] the minimum lap length for compression bars must be 12inches. *table based on uniform building code (icbo, 1997), section 1912.2.2.

Rebar Splice Length Chart Online Shopping

Crsi Rebar Lap Splice Chart

Rebar Splicing and Rebar Sizing Monolithic Dome Institute

Aci Rebar Lap Splice Length Chart

What Is Lap Length Of Reinforcement Bars Lapping Length of Steel Bars

rebar embedment length chart

Rebar Lap Splice Tolerances SexiezPicz Web Porn

Rebar Splicing and Rebar Sizing

28+ Aci Rebar Lap Splice Chart Design Gallery

Rebar Splice Chart A Visual Reference of Charts Chart Master

A Lap Is When Two Pieces Of Reinforcing Bar (Rebar) Are Overlapped To Create A Continuous Line Of Rebar.

A Lap Splice Application Should Be Selected When Two Pieces Of Reinforcing Bar Being Overlapped To Create A Continuous Line Of Rebar.

They Are Dependent Upon Different Factors.

For Astm A615 Grade 60 Bar:

Related Post: