Wire Rope Strength Chart

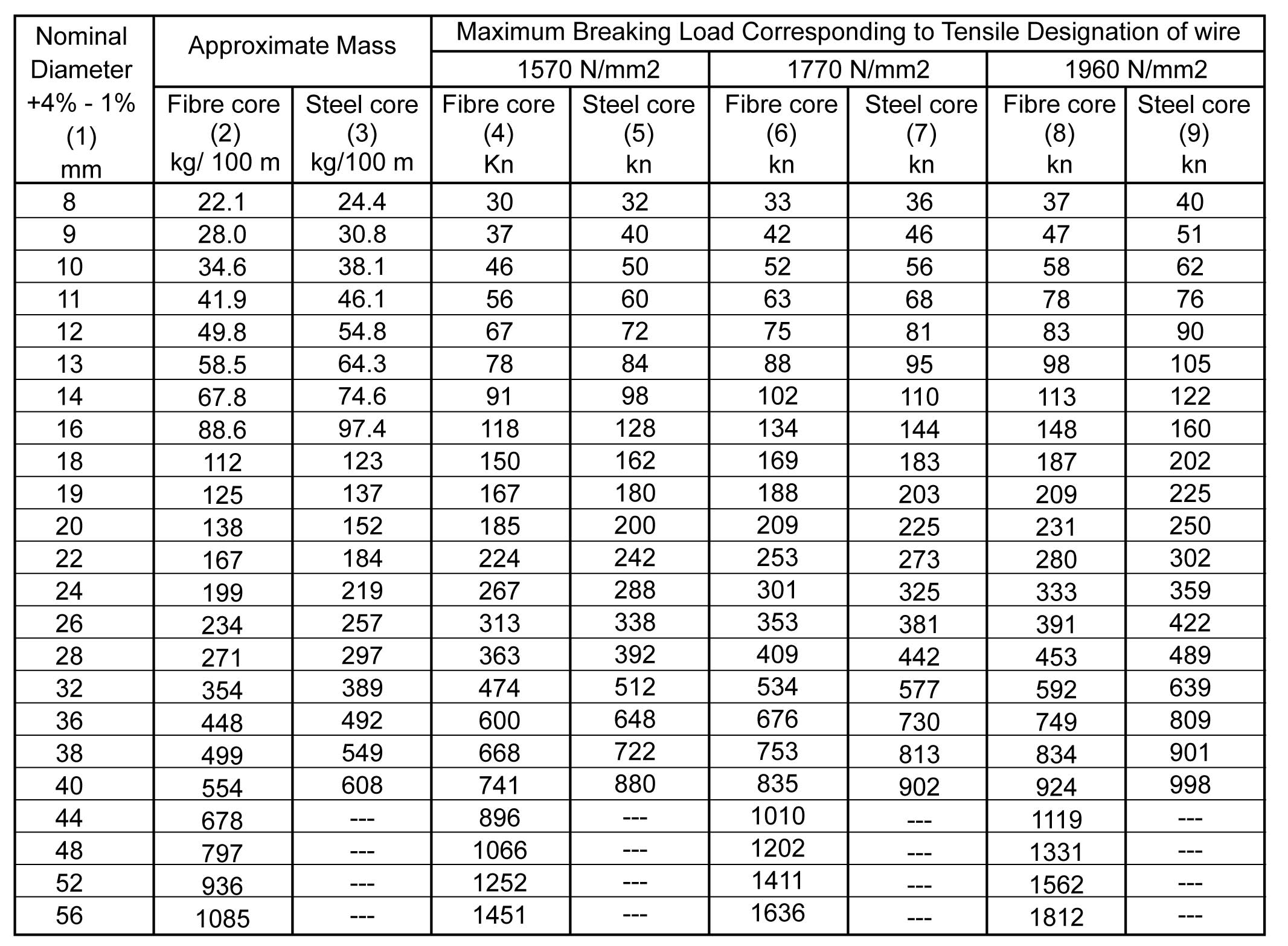

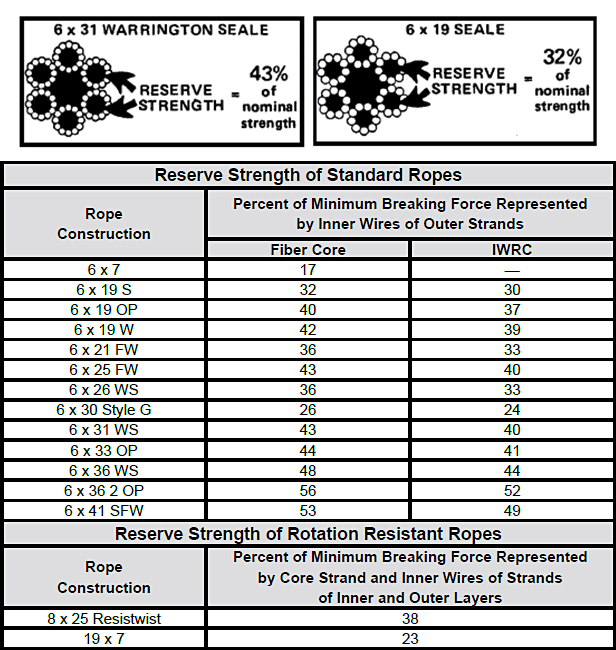

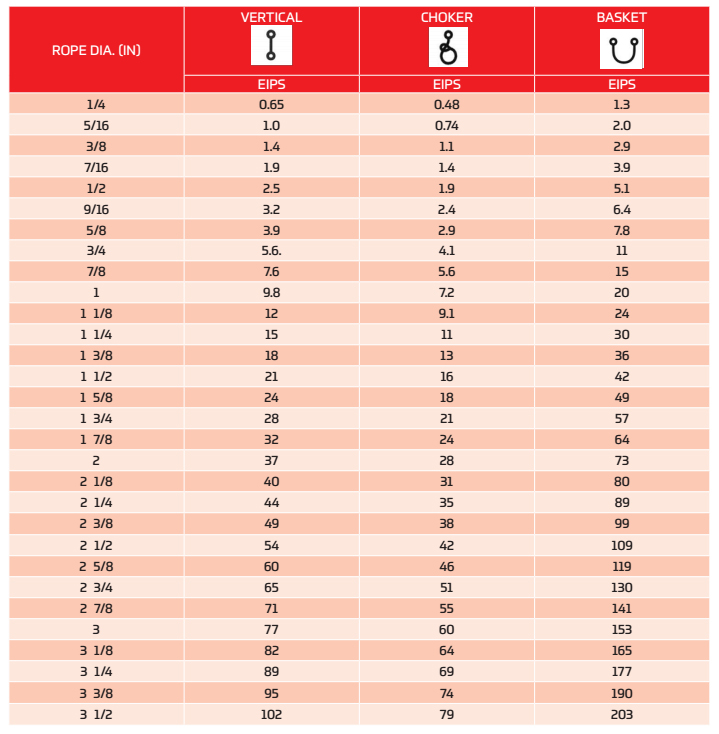

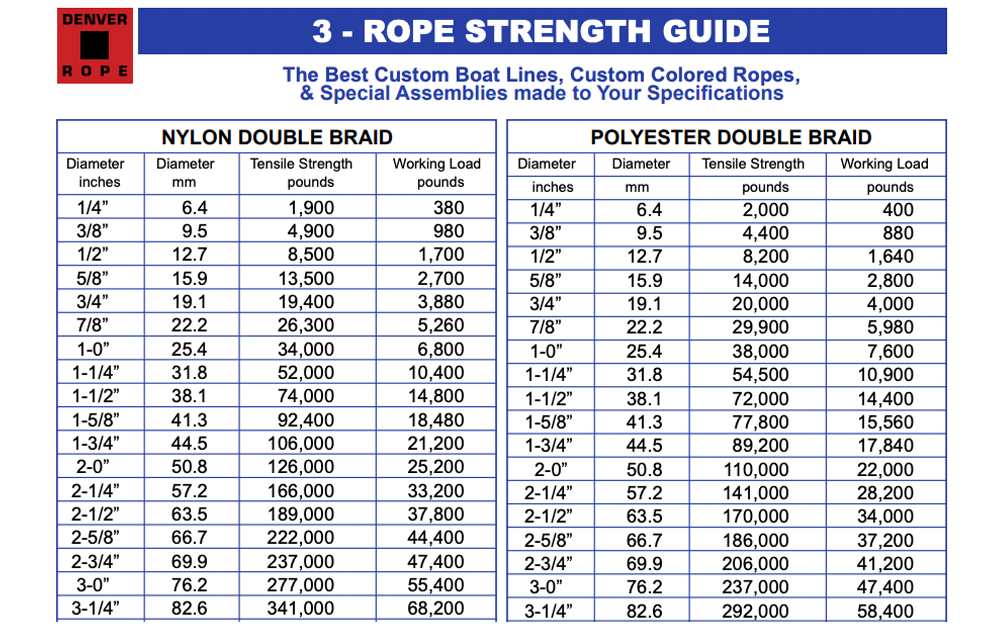

Wire Rope Strength Chart - Web the 6 x 36 classification of wire ropes includes standard 6 strand, round strand ropes with 27 through 49 wires per strand. Web the loss of strength due to bending wire ropes over the sheaves found in common use will not. If a particular rope has a rated strength of 100,000 lbs. Web wire rope user's handbook is a comprehensive guide to the selection, installation, maintenance and safety of wire ropes. Steel cables are made more durable in part due to a manufacturing process known as cold working or cold forming, where the material is shaped below its recrystallization temperature. Web divide the minimum tensile strength by the safety factor to calculate the safe working load limit for a specific cable. Web wire rope strength charts help you easily match the wire rope you need for your lift. And is working under an operating stress of 20,000 lbs., it has a rope strength design factor of 5. While the 6 x 19 ropes give primary important for their fatigue resistance. F = force, weigh t (n) m = mass (kg) g = acceleration of gravity (9.81 m/s2). Web a simple wire rope strength chart can help you keep a close eye on wire rope strengths if find this to be an issue: Nominal strengths of wire ropes provided by industrial rope. It also provides useful tables, charts and formulas for wire rope users. Web divide the minimum tensile strength by the safety factor to calculate the safe. Steel cables are made more durable in part due to a manufacturing process known as cold working or cold forming, where the material is shaped below its recrystallization temperature. If a particular rope has a rated strength of 100,000 lbs. All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot,. If a particular rope has a rated strength of 100,000 lbs. Web a simple wire rope strength chart can help you keep a close eye on wire rope strengths if find this to be an issue: F = force, weigh t (n) m = mass (kg) g = acceleration of gravity (9.81 m/s2). All ropes of the same size, grade. Steel cables are made more durable in part due to a manufacturing process known as cold working or cold forming, where the material is shaped below its recrystallization temperature. All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot, though they do differ depending on the construction type and materials. Web the 6 x 36 classification of wire ropes includes standard 6 strand, round strand ropes with 27 through 49 wires per strand. Characteristics like fatigue resistance and resistance to abrasion are directly affected by the design of strands. Web the rope strength design factor is the ratio of the rated strength of the rope to its operating stress. Nominal. It covers topics such as wire rope construction, properties, applications, inspection, lubrication and storage. It also provides useful tables, charts and formulas for wire rope users. Web divide the minimum tensile strength by the safety factor to calculate the safe working load limit for a specific cable. Web wire rope user's handbook is a comprehensive guide to the selection, installation,. Steel cables are made more durable in part due to a manufacturing process known as cold working or cold forming, where the material is shaped below its recrystallization temperature. If a particular rope has a rated strength of 100,000 lbs. And is working under an operating stress of 20,000 lbs., it has a rope strength design factor of 5. Web. Web the loss of strength due to bending wire ropes over the sheaves found in common use will not. In this reference document (an excerpt from the wire rope users handbook), you will learn what the strands are tested for. Web our galvanized strand products meet or exceed astm specifications a475 and astm a363. F = force, weigh t (n). And is working under an operating stress of 20,000 lbs., it has a rope strength design factor of 5. All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot, though they do differ depending on the construction type and materials used. Web our galvanized strand products meet or exceed astm. Web our galvanized strand products meet or exceed astm specifications a475 and astm a363. Web the 6 x 36 classification of wire ropes includes standard 6 strand, round strand ropes with 27 through 49 wires per strand. Web the loss of strength due to bending wire ropes over the sheaves found in common use will not. Nominal strengths of wire. Web m = f / g (1) where. All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot, though they do differ depending on the construction type and materials used. It also provides useful tables, charts and formulas for wire rope users. Characteristics like fatigue resistance and resistance to abrasion are directly affected by the design of strands. Web the 6 x 36 classification of wire ropes includes standard 6 strand, round strand ropes with 27 through 49 wires per strand. Although their operating properties vary, all have the same weight per foot and the same minimum breaking force, size for size. While the 6 x 19 ropes give primary important for their fatigue resistance. Web our galvanized strand products meet or exceed astm specifications a475 and astm a363. Web a simple wire rope strength chart can help you keep a close eye on wire rope strengths if find this to be an issue: And is working under an operating stress of 20,000 lbs., it has a rope strength design factor of 5. In this reference document (an excerpt from the wire rope users handbook), you will learn what the strands are tested for. Web the loss of strength due to bending wire ropes over the sheaves found in common use will not. They are so handy that you can easily either keep a printed copy or an image on your phone, allowing you to reference it at a moment’s notice. Web rope diameter example to determine the strength efficiency of 1/2 diameter wire rope using a. F = force, weigh t (n) m = mass (kg) g = acceleration of gravity (9.81 m/s2). Web wire rope weights and minimum breaking force.

General Purpose Wire Rope Charleston's Rigging

Wire Rope Chart

General Purpose Arizona Wire Rope

Wire Rope Slings Care Lifting

wireropeslingchart

8X19S FC TS1770N/MM2 Ungalvanized Steel Wire Rope

What Are the Seven Primary Characteristics of Wire Rope?

Wire Rope Lam Hong Group

Wire Rope Sling Capacities All Rigging

Wire Rope Breaking Strength Chart

Web Wire Rope User's Handbook Is A Comprehensive Guide To The Selection, Installation, Maintenance And Safety Of Wire Ropes.

It Covers Topics Such As Wire Rope Construction, Properties, Applications, Inspection, Lubrication And Storage.

Web The Rope Strength Design Factor Is The Ratio Of The Rated Strength Of The Rope To Its Operating Stress.

Steel Cables Are Made More Durable In Part Due To A Manufacturing Process Known As Cold Working Or Cold Forming, Where The Material Is Shaped Below Its Recrystallization Temperature.

Related Post: